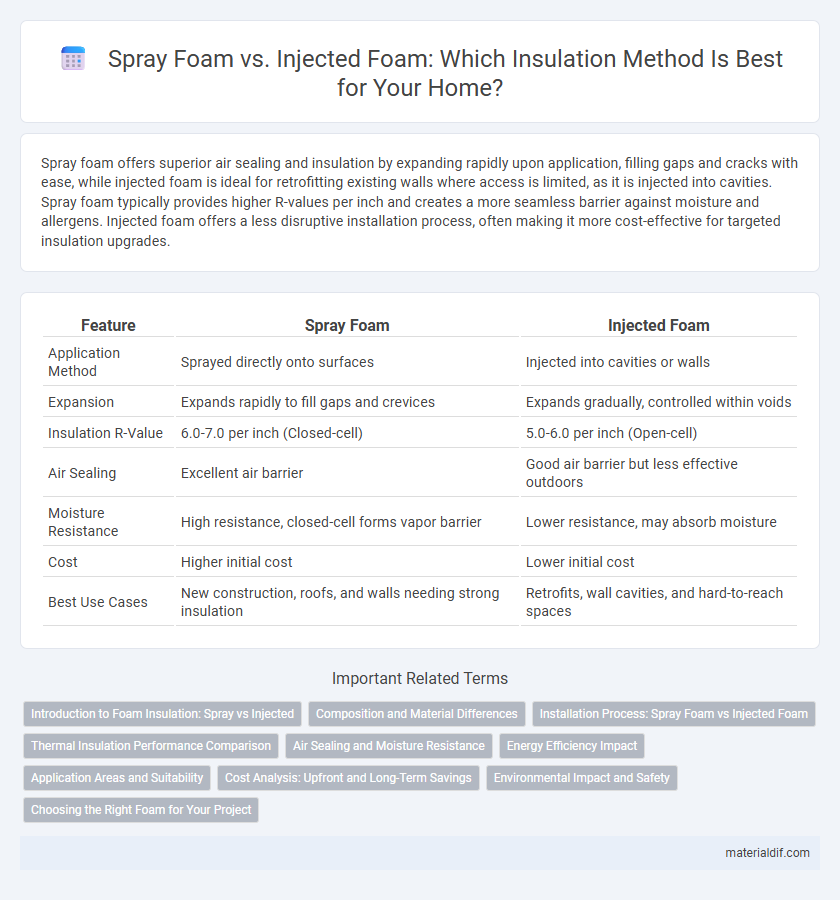

Spray foam offers superior air sealing and insulation by expanding rapidly upon application, filling gaps and cracks with ease, while injected foam is ideal for retrofitting existing walls where access is limited, as it is injected into cavities. Spray foam typically provides higher R-values per inch and creates a more seamless barrier against moisture and allergens. Injected foam offers a less disruptive installation process, often making it more cost-effective for targeted insulation upgrades.

Table of Comparison

| Feature | Spray Foam | Injected Foam |

|---|---|---|

| Application Method | Sprayed directly onto surfaces | Injected into cavities or walls |

| Expansion | Expands rapidly to fill gaps and crevices | Expands gradually, controlled within voids |

| Insulation R-Value | 6.0-7.0 per inch (Closed-cell) | 5.0-6.0 per inch (Open-cell) |

| Air Sealing | Excellent air barrier | Good air barrier but less effective outdoors |

| Moisture Resistance | High resistance, closed-cell forms vapor barrier | Lower resistance, may absorb moisture |

| Cost | Higher initial cost | Lower initial cost |

| Best Use Cases | New construction, roofs, and walls needing strong insulation | Retrofits, wall cavities, and hard-to-reach spaces |

Introduction to Foam Insulation: Spray vs Injected

Spray foam insulation is applied using a spray gun that expands upon contact, creating an airtight and seamless barrier ideal for irregular surfaces and hard-to-reach areas. Injected foam insulation involves pumping foam into cavities through small holes, filling gaps without extensive demolition, most effective in retrofitting existing walls. Both methods enhance thermal resistance (R-value), reduce air leakage, and improve energy efficiency, but selection depends on project specifics like accessibility and surface type.

Composition and Material Differences

Spray foam consists of a liquid polyurethane mixture that expands rapidly upon application, forming a rigid, insulating layer, while injected foam is typically a two-part chemical blend injected into cavities where it expands more slowly to fill voids. Spray foam generally includes isocyanates, polyols, and blowing agents that react instantly to create closed-cell or open-cell structures, whereas injected foam often relies on similar chemicals but with a controlled reaction to target specific cavity shapes. The material density and thermal resistance vary, with spray foam offering higher R-values per inch compared to injected foam, which is optimized for precision filling and structural reinforcement.

Installation Process: Spray Foam vs Injected Foam

Spray foam insulation involves spraying a liquid mixture that rapidly expands and hardens on contact, creating an airtight seal ideal for walls, roofs, and tight spaces. Injected foam is applied by injecting a foam mixture into pre-drilled holes, making it suitable for existing walls without demolition. Spray foam requires specialized equipment and professional expertise for proper application, while injected foam offers a less invasive installation with minimal disruption.

Thermal Insulation Performance Comparison

Spray foam insulation typically offers superior thermal insulation performance with R-values ranging from 6 to 7 per inch for closed-cell varieties, compared to injected foam, which generally provides R-values around 3.5 to 4 per inch. The higher density of spray foam enhances air sealing and reduces thermal bridging, resulting in improved energy efficiency in building envelopes. Injected foam can fill cavities in retrofit applications but often lacks the consistent expansion and coverage of spray foam, leading to potential gaps in thermal insulation.

Air Sealing and Moisture Resistance

Spray foam provides superior air sealing by expanding and filling gaps in walls, ceilings, and floors, creating a continuous barrier that reduces air leakage significantly. Injected foam is effective for retrofitting existing walls, offering moderate air sealing by filling cavities but may leave minor voids compared to spray foam. Both foam types offer strong moisture resistance, but spray foam's denser structure better prevents water vapor transmission and reduces the risk of mold growth.

Energy Efficiency Impact

Spray foam insulation creates an airtight seal by expanding upon application, significantly reducing air leaks and enhancing thermal resistance with an R-value of approximately 6.5 per inch. Injected foam, typically used in closed cavities, provides targeted insulation and can effectively fill gaps but often has a lower R-value around 3.5 to 4 per inch. Spray foam's superior air sealing capabilities and higher R-value result in greater energy efficiency, reducing heating and cooling costs more effectively than injected foam.

Application Areas and Suitability

Spray foam insulation is ideal for irregularly shaped areas, wall cavities, and roofing applications due to its ability to expand and fill gaps, providing an airtight seal. Injected foam is better suited for existing walls and closed cavities where minimal disruption is necessary, as it is injected through small holes and expands inside. Both types offer excellent thermal insulation and moisture control but differ in installation methods and application flexibility.

Cost Analysis: Upfront and Long-Term Savings

Spray foam insulation generally requires higher upfront investment, averaging $1.50 to $3.00 per board foot, but offers superior air sealing that reduces energy bills by up to 50% over time. Injected foam tends to be more affordable initially, around $1.00 to $2.50 per board foot, making it a budget-friendly option for smaller projects with moderate insulation needs. Long-term savings for spray foam outweigh initial costs due to enhanced durability and moisture resistance, which decrease maintenance expenses and improve energy efficiency compared to injected foam.

Environmental Impact and Safety

Spray foam insulation typically contains chemicals like isocyanates that can release volatile organic compounds (VOCs), raising indoor air quality concerns during installation and curing. Injected foam tends to have a lower environmental impact, using less hazardous materials and often providing better airtight sealing that reduces energy consumption and greenhouse gas emissions. Both types require proper protective equipment, but injected foam is generally considered safer for installers and occupants due to controlled application methods and reduced chemical exposure.

Choosing the Right Foam for Your Project

Spray foam offers superior insulation by expanding on application, filling irregular spaces and creating an airtight seal, making it ideal for new construction or hard-to-reach areas. Injected foam is better suited for retrofit projects, as it can be injected into existing walls without demolition, providing efficient thermal and sound insulation in older buildings. Assess project scope, accessibility, and budget to select the foam type that maximizes energy efficiency and structural integrity.

Spray foam vs Injected foam Infographic

materialdif.com

materialdif.com