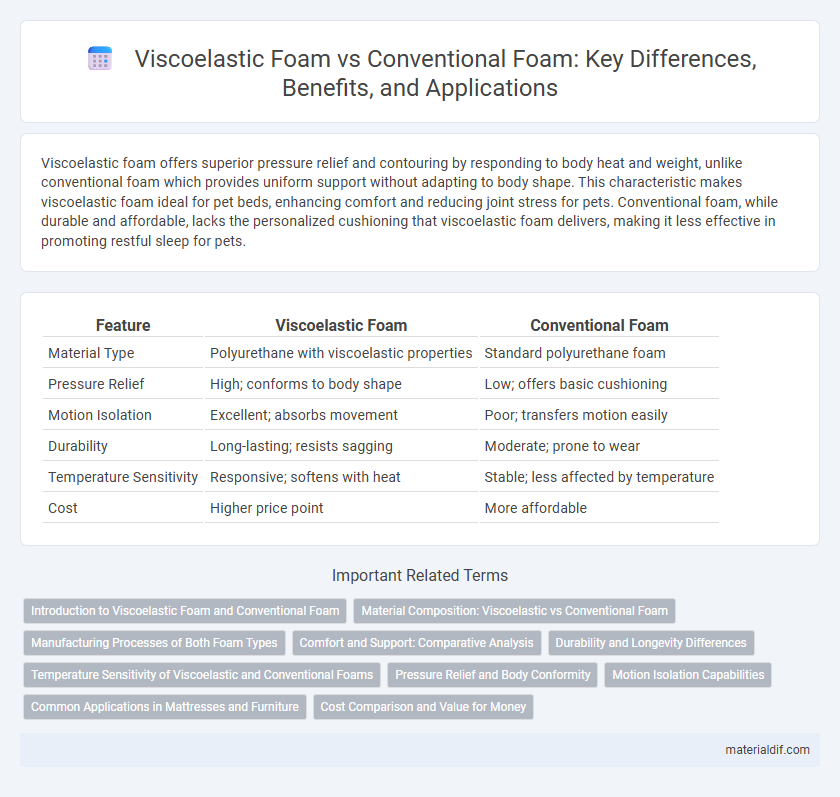

Viscoelastic foam offers superior pressure relief and contouring by responding to body heat and weight, unlike conventional foam which provides uniform support without adapting to body shape. This characteristic makes viscoelastic foam ideal for pet beds, enhancing comfort and reducing joint stress for pets. Conventional foam, while durable and affordable, lacks the personalized cushioning that viscoelastic foam delivers, making it less effective in promoting restful sleep for pets.

Table of Comparison

| Feature | Viscoelastic Foam | Conventional Foam |

|---|---|---|

| Material Type | Polyurethane with viscoelastic properties | Standard polyurethane foam |

| Pressure Relief | High; conforms to body shape | Low; offers basic cushioning |

| Motion Isolation | Excellent; absorbs movement | Poor; transfers motion easily |

| Durability | Long-lasting; resists sagging | Moderate; prone to wear |

| Temperature Sensitivity | Responsive; softens with heat | Stable; less affected by temperature |

| Cost | Higher price point | More affordable |

Introduction to Viscoelastic Foam and Conventional Foam

Viscoelastic foam, often referred to as memory foam, is characterized by its temperature-sensitive properties that allow it to contour closely to the body's shape, providing superior pressure relief and support compared to conventional foam. Conventional foam, typically made from polyurethane, offers varying densities and firmness but lacks the adaptive responsiveness of viscoelastic foam, making it more prone to quicker wear and less effective in evenly distributing body weight. The unique cell structure of viscoelastic foam slows its return to original shape, enhancing comfort and reducing motion transfer, features not commonly found in traditional foam materials.

Material Composition: Viscoelastic vs Conventional Foam

Viscoelastic foam, composed primarily of polyurethane combined with viscoelastic polymers, exhibits slow recovery and pressure-sensitive properties that conform closely to body contours. Conventional foam, typically made from standard polyurethane without viscoelastic additives, offers quicker rebound and less contouring effect. The unique molecular structure of viscoelastic foam provides enhanced energy absorption and durability compared to the open-cell matrix of conventional foam.

Manufacturing Processes of Both Foam Types

Viscoelastic foam is manufactured through a specialized process involving the reaction of polyurethane with additional chemicals such as viscoelastic polyols, resulting in a denser, more temperature-sensitive foam that molds to body contours. Conventional foam production utilizes a simpler polyurethane formulation and fewer additives, creating a more open-cell structure characterized by faster cooling and higher airflow. The manufacturing of viscoelastic foam requires precise control of chemical reactions and curing times to achieve its distinctive slow-recovery properties, whereas conventional foam leverages a quicker, less specialized production cycle.

Comfort and Support: Comparative Analysis

Viscoelastic foam, also known as memory foam, offers superior comfort by contouring to the body's shape, providing enhanced pressure relief and support compared to conventional foam, which tends to be firmer and less adaptive. The viscoelastic material reduces motion transfer, making it ideal for shared sleeping surfaces, while conventional foam lacks this dynamic response, often resulting in uneven support. Studies show that viscoelastic foam improves spinal alignment and reduces discomfort, leading to better sleep quality versus traditional polyurethane foam.

Durability and Longevity Differences

Viscoelastic foam, also known as memory foam, exhibits superior durability compared to conventional foam due to its higher density and resilience, which enables it to retain shape and support over extended use. Unlike conventional foam, which tends to degrade, compress, and lose bounce quickly under repetitive stress, viscoelastic foam withstands wear and maintains structural integrity for years. This longevity makes viscoelastic foam a preferred material in mattresses and cushions where sustained comfort and durability are critical.

Temperature Sensitivity of Viscoelastic and Conventional Foams

Viscoelastic foam exhibits high temperature sensitivity, becoming softer and more pliable as it warms to body heat, allowing for enhanced contouring and pressure relief. Conventional foam maintains a more consistent firmness across temperature variations, providing stable support without significant changes in texture or density. This temperature-responsive behavior of viscoelastic foam is crucial for applications requiring adaptive cushioning and comfort, whereas conventional foam suits environments needing steady structural integrity.

Pressure Relief and Body Conformity

Viscoelastic foam, often known as memory foam, provides superior pressure relief by evenly distributing body weight and reducing stress on pressure points, unlike conventional foam which tends to retain less body heat and offer firmer support. Its high body conformity contours closely to the body's shape, enhancing comfort and support, while conventional foam maintains a more rigid structure that does not adapt as closely to individual body curves. The viscoelastic properties allow for gradual response to pressure, improving spinal alignment and reducing discomfort during prolonged use.

Motion Isolation Capabilities

Viscoelastic foam, commonly known as memory foam, offers superior motion isolation capabilities compared to conventional polyurethane foam due to its high density and ability to conform closely to body contours. This unique property minimizes motion transfer, making it ideal for shared sleeping surfaces where disturbances from a partner's movement need to be reduced. Conventional foam typically exhibits more bounce and less contouring, resulting in greater motion transfer and less effective isolation.

Common Applications in Mattresses and Furniture

Viscoelastic foam, known for its slow response to pressure and superior contouring properties, is widely used in mattresses and furniture to provide enhanced comfort and pressure relief. Conventional foam, typically polyurethane-based, offers firmer support and is more common in budget mattresses and standard furniture cushioning due to its durability and cost-effectiveness. Both foams serve distinct purposes in the bedding and furniture industry, with viscoelastic foam favored for premium ergonomic benefits and conventional foam for affordable resilience.

Cost Comparison and Value for Money

Viscoelastic foam typically costs 20-40% more than conventional foam due to its advanced material technology and superior pressure-relief properties. Despite the higher initial price, viscoelastic foam offers greater durability, improved comfort, and better support, leading to longer lifespan and enhanced value for money. Conventional foam provides a more budget-friendly option but may require frequent replacement, resulting in higher long-term expenses.

Viscoelastic foam vs Conventional foam Infographic

materialdif.com

materialdif.com