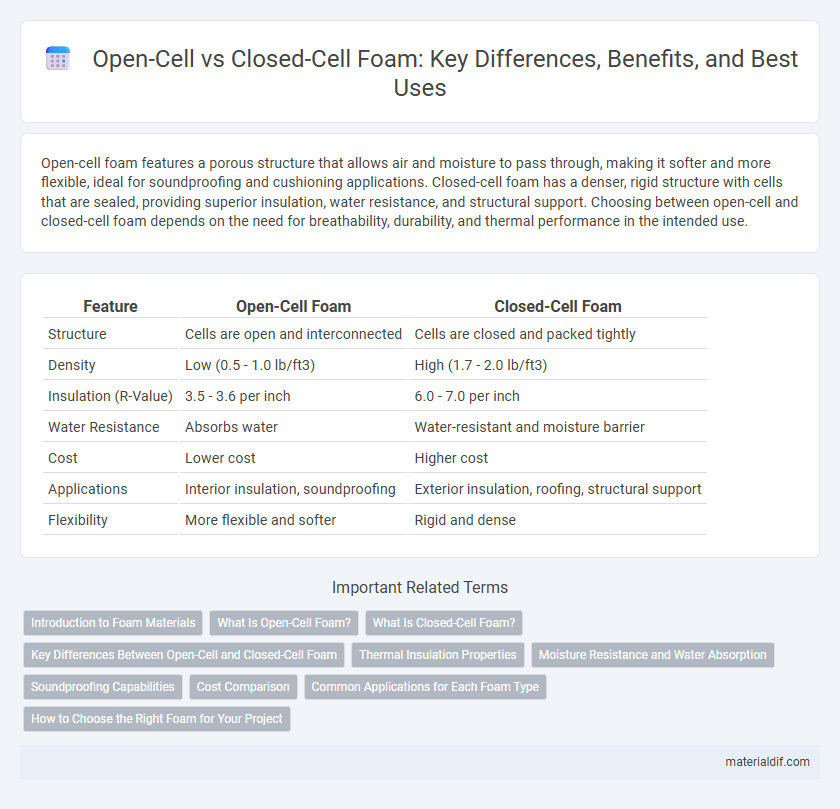

Open-cell foam features a porous structure that allows air and moisture to pass through, making it softer and more flexible, ideal for soundproofing and cushioning applications. Closed-cell foam has a denser, rigid structure with cells that are sealed, providing superior insulation, water resistance, and structural support. Choosing between open-cell and closed-cell foam depends on the need for breathability, durability, and thermal performance in the intended use.

Table of Comparison

| Feature | Open-Cell Foam | Closed-Cell Foam |

|---|---|---|

| Structure | Cells are open and interconnected | Cells are closed and packed tightly |

| Density | Low (0.5 - 1.0 lb/ft3) | High (1.7 - 2.0 lb/ft3) |

| Insulation (R-Value) | 3.5 - 3.6 per inch | 6.0 - 7.0 per inch |

| Water Resistance | Absorbs water | Water-resistant and moisture barrier |

| Cost | Lower cost | Higher cost |

| Applications | Interior insulation, soundproofing | Exterior insulation, roofing, structural support |

| Flexibility | More flexible and softer | Rigid and dense |

Introduction to Foam Materials

Open-cell foam features interconnected pores that allow air and moisture to pass through, making it lightweight and flexible, ideal for cushioning and sound absorption applications. Closed-cell foam consists of tightly packed cells filled with gas, offering higher density, superior insulation, and water resistance, commonly used in thermal insulation and flotation devices. Both foam types are derived from polymer-based materials such as polyurethane, polyethylene, or polystyrene, each selected based on specific performance requirements.

What Is Open-Cell Foam?

Open-cell foam consists of interconnected cells that allow air and moisture to pass through, making it lightweight and breathable. This type of foam provides excellent sound absorption and insulation but has a lower density compared to closed-cell foam, which reduces its moisture resistance. Commonly used in furniture cushions, acoustic panels, and insulation where breathability is essential, open-cell foam offers flexibility and comfort.

What Is Closed-Cell Foam?

Closed-cell foam is a dense, rigid material composed of cells that are completely enclosed and not interconnected, providing superior insulation and moisture resistance compared to open-cell foam. It boasts higher structural strength, making it ideal for applications requiring durability, such as roofing, insulation panels, and flotation devices. The foam's low permeability also enhances its thermal performance by minimizing air and water vapor infiltration.

Key Differences Between Open-Cell and Closed-Cell Foam

Open-cell foam features interconnected cells that allow air and moisture to pass through, making it softer and more flexible, ideal for soundproofing and cushioning applications. Closed-cell foam consists of tightly packed cells filled with gas, providing higher density, superior insulation, and increased water resistance, often used in thermal insulation and structural support. The key differences include cell structure, density, moisture resistance, and insulation capabilities, which determine the suitability of each foam type for specific industries and environments.

Thermal Insulation Properties

Open-cell foam features a porous structure that allows air to flow freely, resulting in lower thermal insulation performance compared to closed-cell foam. Closed-cell foam has dense, tightly packed cells filled with gas, providing superior thermal resistance and minimizing heat transfer. This makes closed-cell foam ideal for applications requiring high energy efficiency and moisture resistance.

Moisture Resistance and Water Absorption

Closed-cell foam offers superior moisture resistance and minimal water absorption due to its dense, impermeable structure, making it ideal for applications exposed to wet environments. Open-cell foam, characterized by its porous and breathable nature, absorbs water more easily, leading to reduced insulation performance and potential mold growth. Selecting the appropriate foam type depends on evaluating specific moisture exposure and durability requirements in construction or packaging projects.

Soundproofing Capabilities

Open-cell foam absorbs sound waves effectively due to its porous structure, making it ideal for reducing echo and ambient noise within rooms. Closed-cell foam offers superior soundproofing by creating a dense barrier that blocks external noise and prevents sound transmission between spaces. The choice between open-cell and closed-cell foam depends on whether sound absorption or sound blockage is the primary goal.

Cost Comparison

Open-cell foam generally costs less than closed-cell foam due to its lower density and simpler manufacturing process. Closed-cell foam, with its higher density and superior insulating properties, commands a higher price but offers better moisture resistance and durability. Budget considerations often influence the choice between these foams, balancing upfront cost against long-term performance and efficiency benefits.

Common Applications for Each Foam Type

Open-cell foam is commonly used in soundproofing, cushioning, and insulation for interior walls due to its breathability and softness. Closed-cell foam finds frequent applications in marine flotation devices, insulation panels, and high-impact protective gear because of its rigidity, water resistance, and high insulation value. Both foam types are essential in packaging, with open-cell providing shock absorption and closed-cell offering moisture barriers.

How to Choose the Right Foam for Your Project

Open-cell foam offers superior breathability and flexibility, making it ideal for soundproofing and cushioning applications, while closed-cell foam provides higher density, moisture resistance, and structural support, suited for insulation and flotation purposes. Choose open-cell foam when softness and airflow are critical, and opt for closed-cell foam for environments requiring durability and water resistance. Assess the project's specific needs regarding insulation, weight, and exposure to moisture to select the most effective foam type.

Open-cell foam vs Closed-cell foam Infographic

materialdif.com

materialdif.com