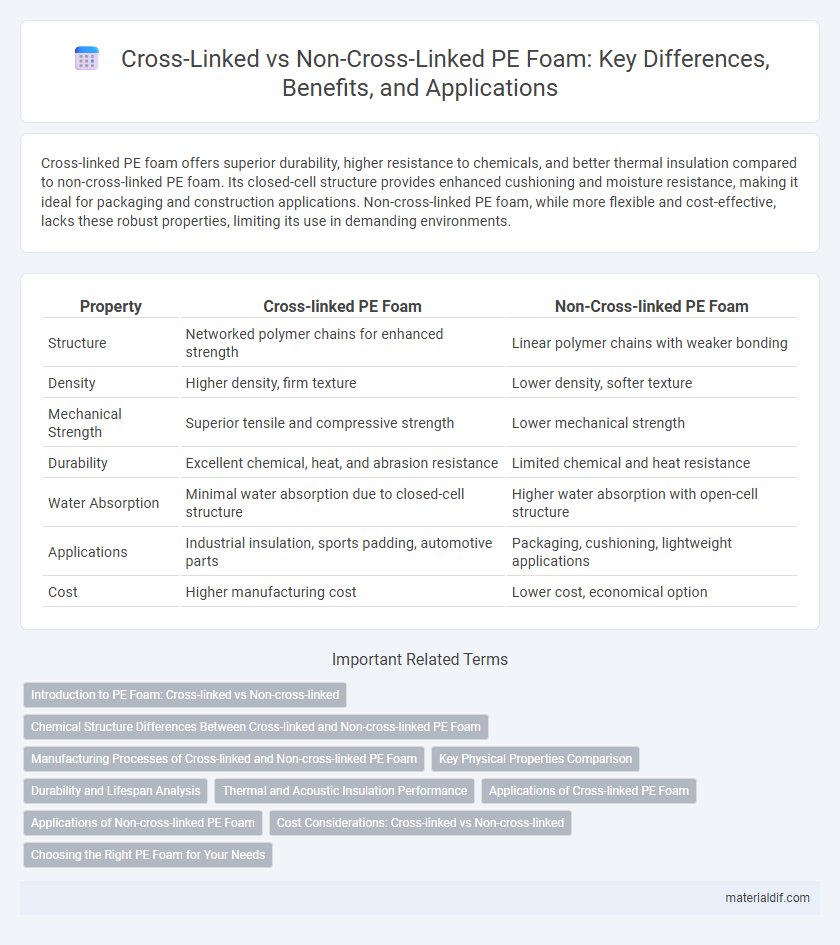

Cross-linked PE foam offers superior durability, higher resistance to chemicals, and better thermal insulation compared to non-cross-linked PE foam. Its closed-cell structure provides enhanced cushioning and moisture resistance, making it ideal for packaging and construction applications. Non-cross-linked PE foam, while more flexible and cost-effective, lacks these robust properties, limiting its use in demanding environments.

Table of Comparison

| Property | Cross-linked PE Foam | Non-Cross-linked PE Foam |

|---|---|---|

| Structure | Networked polymer chains for enhanced strength | Linear polymer chains with weaker bonding |

| Density | Higher density, firm texture | Lower density, softer texture |

| Mechanical Strength | Superior tensile and compressive strength | Lower mechanical strength |

| Durability | Excellent chemical, heat, and abrasion resistance | Limited chemical and heat resistance |

| Water Absorption | Minimal water absorption due to closed-cell structure | Higher water absorption with open-cell structure |

| Applications | Industrial insulation, sports padding, automotive parts | Packaging, cushioning, lightweight applications |

| Cost | Higher manufacturing cost | Lower cost, economical option |

Introduction to PE Foam: Cross-linked vs Non-cross-linked

Cross-linked PE foam features a networked molecular structure that enhances durability, chemical resistance, and compression recovery, making it ideal for high-performance applications. Non-cross-linked PE foam has a linear polymer structure with lower density, offering superior flexibility and cost-effectiveness for general cushioning and packaging needs. The cross-linking process significantly alters cellular structure, resulting in improved mechanical properties and longer lifespan in demanding environments.

Chemical Structure Differences Between Cross-linked and Non-cross-linked PE Foam

Cross-linked PE foam features a three-dimensional polymer network formed by covalent bonds, enhancing its thermal stability, mechanical strength, and chemical resistance compared to non-cross-linked PE foam, which consists of linear polymer chains without interconnections. This chemical structure difference results in cross-linked PE foam having improved elasticity and durability, whereas non-cross-linked PE foam tends to be softer and less resistant to deformation. The cross-linking process reduces the polymer's molecular mobility, leading to superior performance in demanding applications such as insulation and impact protection.

Manufacturing Processes of Cross-linked and Non-cross-linked PE Foam

Cross-linked PE foam is produced through chemical or physical methods that create bonds between polymer chains, enhancing its structural integrity and thermal stability. Non-cross-linked PE foam, in contrast, is typically manufactured by mechanically foaming polyethylene without forming these interchain bonds, resulting in a softer, less durable material. The cross-linking process involves high temperatures or irradiation, which significantly improves foam resilience compared to the simpler extrusion or molding techniques used for non-cross-linked variants.

Key Physical Properties Comparison

Cross-linked PE foam exhibits higher tensile strength and improved compressive resistance compared to non-cross-linked PE foam, making it more durable under mechanical stress. It also shows superior chemical and thermal stability due to its cross-linked molecular structure, which enhances its resilience in harsh environments. Non-cross-linked PE foam, while more flexible and lightweight, typically has lower density and reduced resistance to deformation and wear.

Durability and Lifespan Analysis

Cross-linked PE foam exhibits superior durability compared to non-cross-linked PE foam due to its enhanced molecular structure, which increases resistance to compression, wear, and chemical degradation. This improved structural integrity extends the lifespan of cross-linked PE foam, making it ideal for long-term applications in insulation, cushioning, and sealing. Non-cross-linked PE foam, while cost-effective, tends to degrade faster under mechanical stress and environmental exposure, resulting in a shorter service life.

Thermal and Acoustic Insulation Performance

Cross-linked PE foam exhibits superior thermal insulation due to its closed-cell structure, which significantly reduces heat transfer and enhances energy efficiency. Its dense network of interconnected polymer chains also provides better acoustic insulation by effectively dampening sound waves and minimizing noise transmission compared to non-cross-linked PE foam. Non-cross-linked PE foam, with its open-cell composition, offers less resistance to heat flow and sound, making it less effective for high-performance thermal and acoustic applications.

Applications of Cross-linked PE Foam

Cross-linked PE foam offers superior durability, chemical resistance, and thermal insulation, making it ideal for automotive gaskets, pipe insulation, and sports equipment padding. Its closed-cell structure provides enhanced water and vapor resistance, which is essential in marine and construction applications. The foam's resilience under compression extends its use to packaging sensitive electronics and medical devices.

Applications of Non-cross-linked PE Foam

Non-cross-linked PE foam is widely used in packaging, cushioning, and insulation due to its lightweight and flexible nature, providing effective shock absorption and thermal resistance. It is commonly applied in protective packaging for electronics, automotive components, and consumer goods, where moderate durability suffices. The foam's open-cell structure enhances breathability and moisture resistance, making it suitable for sports equipment padding and gasket materials.

Cost Considerations: Cross-linked vs Non-cross-linked

Cross-linked PE foam typically incurs higher manufacturing costs due to the complex cross-linking process that enhances durability and chemical resistance. Non-cross-linked PE foam is more cost-effective, offering basic cushioning and insulation properties ideal for budget-conscious applications. Choosing between them depends on balancing upfront expenses against long-term performance and lifespan requirements.

Choosing the Right PE Foam for Your Needs

Cross-linked PE foam offers superior durability, higher resilience, and enhanced chemical resistance compared to non-cross-linked PE foam, making it ideal for heavy-duty applications and long-term use. Non-cross-linked PE foam is more flexible, softer, and cost-effective, suitable for cushioning, insulation, and packaging where high mechanical strength is not critical. Selecting the right PE foam depends on balancing factors such as required toughness, flexibility, environmental exposure, and budget constraints.

Cross-linked PE foam vs Non-cross-linked PE foam Infographic

materialdif.com

materialdif.com