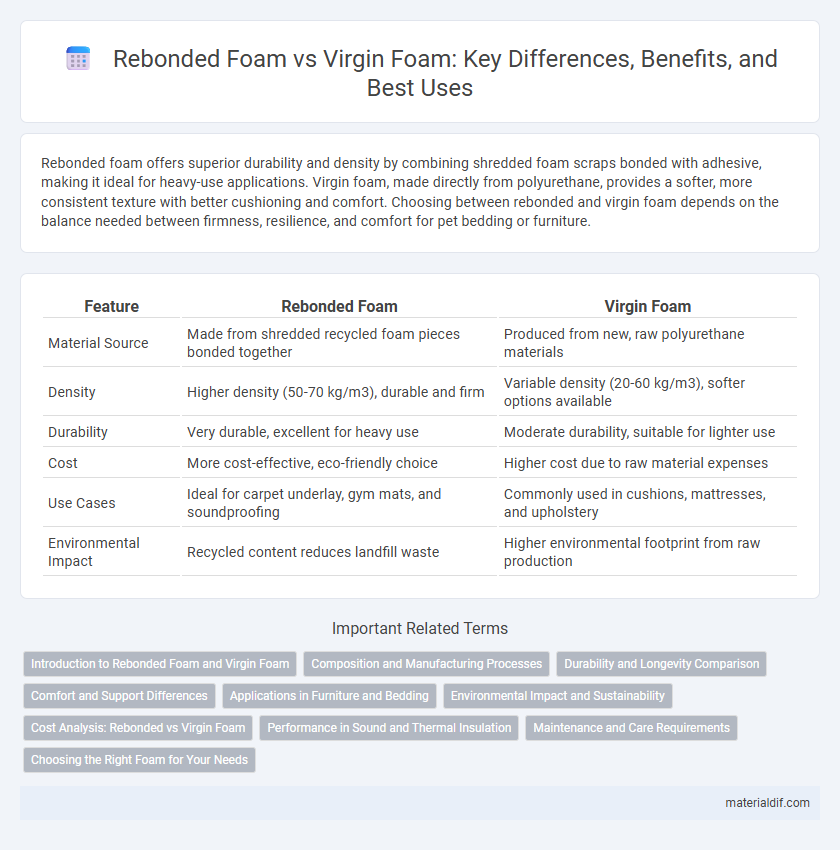

Rebonded foam offers superior durability and density by combining shredded foam scraps bonded with adhesive, making it ideal for heavy-use applications. Virgin foam, made directly from polyurethane, provides a softer, more consistent texture with better cushioning and comfort. Choosing between rebonded and virgin foam depends on the balance needed between firmness, resilience, and comfort for pet bedding or furniture.

Table of Comparison

| Feature | Rebonded Foam | Virgin Foam |

|---|---|---|

| Material Source | Made from shredded recycled foam pieces bonded together | Produced from new, raw polyurethane materials |

| Density | Higher density (50-70 kg/m3), durable and firm | Variable density (20-60 kg/m3), softer options available |

| Durability | Very durable, excellent for heavy use | Moderate durability, suitable for lighter use |

| Cost | More cost-effective, eco-friendly choice | Higher cost due to raw material expenses |

| Use Cases | Ideal for carpet underlay, gym mats, and soundproofing | Commonly used in cushions, mattresses, and upholstery |

| Environmental Impact | Recycled content reduces landfill waste | Higher environmental footprint from raw production |

Introduction to Rebonded Foam and Virgin Foam

Rebonded foam is manufactured by compressing shredded scrap foam bonded together with polyurethane adhesive, offering high density and durability optimal for heavy-duty applications. Virgin foam is produced directly from liquid polyurethane without recycling, providing consistent cell structure and cushioning suitable for comfort-focused products. Understanding the differences in composition and performance helps determine their best use in furniture, bedding, insulation, or packaging industries.

Composition and Manufacturing Processes

Rebonded foam is produced by shredding and fusing recycled foam scraps using adhesives and heat, resulting in a dense, firm material composed primarily of polyurethane remnants bonded together. Virgin foam is created from raw polyurethane chemicals through a controlled foaming process, allowing precise control over density, cell structure, and firmness. The manufacturing of virgin foam ensures consistent quality and performance, whereas rebonded foam emphasizes sustainability through material reuse but may vary in composition and texture due to its recycled nature.

Durability and Longevity Comparison

Rebonded foam, made from shredded recycled foam pieces bonded together, offers enhanced durability due to its dense structure, making it ideal for high-impact applications and extended use. Virgin foam, crafted from new polyurethane without recycled content, typically provides superior resilience and uncompressed longevity, maintaining shape and cushioning over time with less risk of degradation. When evaluating durability and longevity, rebonded foam excels in strength and cost-effectiveness, while virgin foam ensures consistent performance and greater lifespan under normal usage conditions.

Comfort and Support Differences

Rebonded foam offers firmer support due to its dense composition made from shredded foam pieces bonded together, making it ideal for heavy-duty applications requiring durability and resistance to compression. Virgin foam, produced from fresh polyurethane without recycled content, provides a softer, more consistent comfort level with better cushioning and pressure relief, enhancing overall comfort in furniture and bedding. The choice between rebonded and virgin foam hinges on desired firmness and longevity, with virgin foam favoring comfort and rebonded foam prioritizing robust support.

Applications in Furniture and Bedding

Rebonded foam offers superior density and durability, making it ideal for high-traffic furniture such as sofas and office chairs where long-lasting support is essential. Virgin foam provides enhanced softness and resilience, preferred in bedding applications like mattresses and pillows for optimal comfort and pressure relief. Selecting between rebonded and virgin foam depends on balancing firmness and cushioning tailored to specific furniture and bedding needs.

Environmental Impact and Sustainability

Rebonded foam is made from recycled foam scraps, significantly reducing landfill waste and lowering the demand for new raw materials, which enhances its environmental sustainability compared to virgin foam. Virgin foam production relies on petrochemicals and generates higher carbon emissions, contributing to environmental degradation and resource depletion. Choosing rebonded foam supports circular economy principles by minimizing waste and conserving resources, making it a more eco-friendly option in foam manufacturing.

Cost Analysis: Rebonded vs Virgin Foam

Rebonded foam offers significant cost savings compared to virgin foam due to its production from recycled foam scraps, reducing raw material expenses by up to 50%. Virgin foam, while more expensive due to higher quality and consistency, typically costs 30-60% more per cubic foot than rebonded foam. Businesses often prefer rebonded foam for budget-sensitive projects without demanding premium softness or uniformity, striking a balance between affordability and performance.

Performance in Sound and Thermal Insulation

Rebonded foam offers superior sound insulation due to its dense structure, effectively absorbing noise and vibrations in various applications. Virgin foam excels in thermal insulation with its closed-cell composition, which reduces heat transfer and maintains consistent temperature control. Both foams provide distinct performance benefits, with rebonded foam favored for acoustic barriers and virgin foam preferred for energy-efficient thermal management.

Maintenance and Care Requirements

Rebonded foam requires more frequent inspection and cleaning due to its composite nature, which can trap dust and moisture more easily than virgin foam. Virgin foam demonstrates superior durability and typically needs less intensive maintenance, retaining its shape and cushioning properties longer under regular use. Proper care for rebonded foam involves using gentle vacuuming and spot cleaning to maintain its integrity, whereas virgin foam benefits from periodic airing and avoiding prolonged compression.

Choosing the Right Foam for Your Needs

Choosing the right foam depends on your specific application, where rebonded foam offers superior density and durability due to its composite nature, making it ideal for heavy-use furniture and gym mats. Virgin foam provides consistent quality and softness, preferred for cushioning in mattresses and pillows where comfort and uniformity are priorities. Understanding the balance between rebonded foam's sturdiness and virgin foam's plush feel ensures optimal performance and longevity in your project.

Rebonded foam vs Virgin foam Infographic

materialdif.com

materialdif.com