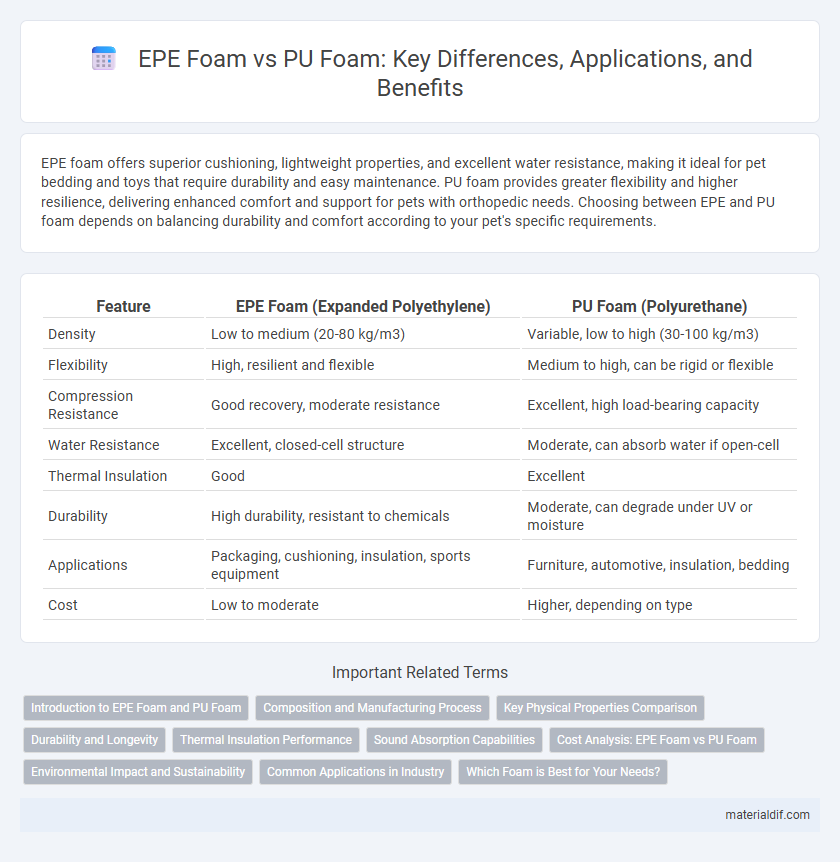

EPE foam offers superior cushioning, lightweight properties, and excellent water resistance, making it ideal for pet bedding and toys that require durability and easy maintenance. PU foam provides greater flexibility and higher resilience, delivering enhanced comfort and support for pets with orthopedic needs. Choosing between EPE and PU foam depends on balancing durability and comfort according to your pet's specific requirements.

Table of Comparison

| Feature | EPE Foam (Expanded Polyethylene) | PU Foam (Polyurethane) |

|---|---|---|

| Density | Low to medium (20-80 kg/m3) | Variable, low to high (30-100 kg/m3) |

| Flexibility | High, resilient and flexible | Medium to high, can be rigid or flexible |

| Compression Resistance | Good recovery, moderate resistance | Excellent, high load-bearing capacity |

| Water Resistance | Excellent, closed-cell structure | Moderate, can absorb water if open-cell |

| Thermal Insulation | Good | Excellent |

| Durability | High durability, resistant to chemicals | Moderate, can degrade under UV or moisture |

| Applications | Packaging, cushioning, insulation, sports equipment | Furniture, automotive, insulation, bedding |

| Cost | Low to moderate | Higher, depending on type |

Introduction to EPE Foam and PU Foam

EPE foam (Expanded Polyethylene) is a lightweight, resilient material known for its excellent cushioning, thermal insulation, and water resistance, often used in packaging and sports equipment. PU foam (Polyurethane) is a versatile polymer foam with superior flexibility and durability, commonly utilized in furniture, automotive seating, and thermal insulation. Both foams offer distinct properties, with EPE foam excelling in impact absorption and PU foam providing enhanced comfort and structural support.

Composition and Manufacturing Process

EPE foam (expanded polyethylene) is composed of polyethylene beads that expand through a steam heating process, resulting in a closed-cell, lightweight material with excellent flexibility and cushioning properties. PU foam (polyurethane) is synthesized by reacting polyols with diisocyanates, forming a polymer matrix through chemical foaming agents that create an open or closed-cell structure, offering varied density and firmness options. The manufacturing of EPE foam relies on bead expansion and molding techniques, while PU foam production involves chemical reactions and curing processes that allow for greater customization in texture and durability.

Key Physical Properties Comparison

EPE foam offers superior resilience and impact absorption with a density range of 16-40 kg/m3, making it ideal for packaging and cushioning applications, while PU foam, characterized by a density of 30-80 kg/m3, excels in thermal insulation and comfort due to its higher compressive strength and flexibility. EPE foam features closed-cell structure providing excellent water resistance and dimensional stability, whereas PU foam's open-cell structure delivers better breathability but lower moisture resistance. The thermal conductivity of EPE foam is typically around 0.038 W/m*K, compared to PU foam's lower thermal conductivity of 0.022-0.028 W/m*K, highlighting PU's enhanced insulation capability.

Durability and Longevity

EPE foam exhibits superior durability and longevity compared to PU foam due to its closed-cell structure, which provides excellent resistance to moisture, chemicals, and physical impacts. PU foam tends to degrade faster under prolonged exposure to UV radiation and compression, resulting in reduced lifespan and structural integrity. For applications demanding long-term performance and resilience in harsh environments, EPE foam is the preferred choice.

Thermal Insulation Performance

EPE foam offers superior thermal insulation performance due to its closed-cell structure, which effectively minimizes heat transfer and moisture absorption. PU foam also provides good insulation but tends to have higher thermal conductivity compared to EPE foam, making EPE a more efficient choice for retaining temperature. The lightweight and durable nature of EPE foam further enhances its application in thermal insulation across construction and packaging industries.

Sound Absorption Capabilities

EPE foam offers moderate sound absorption due to its closed-cell structure, making it suitable for basic noise reduction applications. PU foam, especially open-cell types, exhibits superior acoustic insulation by effectively trapping air and dampening sound waves across a wider frequency range. Industries prioritize PU foam for soundproofing in automotive, construction, and audio equipment due to its enhanced sound absorption capabilities compared to EPE foam.

Cost Analysis: EPE Foam vs PU Foam

EPE foam typically offers a lower cost per unit compared to PU foam due to its simpler manufacturing process and raw material expenses. PU foam, while more expensive, provides superior cushioning and resilience, which can justify higher upfront costs in applications requiring durability. Choosing between EPE and PU foam depends on budget constraints and performance requirements, with EPE foam favored for cost-effective packaging and PU foam preferred for high-performance comfort solutions.

Environmental Impact and Sustainability

EPE foam, made from expanded polyethylene, is lightweight, recyclable, and has lower environmental impact due to its non-toxic composition and longer lifecycle compared to PU foam, which is derived from petroleum with lingering chemical pollutants. PU foam, or polyurethane, is less biodegradable and poses challenges in waste management and off-gassing of volatile organic compounds, impacting indoor air quality and contributing to environmental pollution. Sustainable alternatives emphasize EPE foam's recyclability and reduced carbon footprint, aligning with eco-friendly manufacturing practices and circular economy initiatives.

Common Applications in Industry

EPE foam is widely used in packaging, cushioning, and insulation due to its lightweight, resilient, and chemical-resistant properties, making it ideal for protecting electronics and fragile goods. PU foam is primarily employed in furniture, automotive seating, and thermal insulation because of its superior comfort, durability, and excellent thermal resistance. Both foams serve crucial roles in industries requiring impact absorption, noise reduction, and temperature control.

Which Foam is Best for Your Needs?

EPE foam offers superior flexibility, lightweight properties, and excellent moisture resistance, making it ideal for packaging and cushioning applications. PU foam excels in durability, high-density support, and thermal insulation, commonly used in furniture and bedding. Choosing the best foam depends on specific needs such as impact protection, comfort, or insulation, with EPE favored for packaging and PU preferred for structural support.

EPE foam vs PU foam Infographic

materialdif.com

materialdif.com