Polymer-modified concrete enhances durability and flexibility compared to ordinary Portland cement concrete by incorporating polymers that improve bonding and reduce permeability. This upgrade results in superior resistance to chemical attacks, abrasion, and cracking, making it ideal for demanding environments. Ordinary Portland cement concrete, while cost-effective and widely used, lacks the enhanced mechanical properties and resistance offered by polymer modifications.

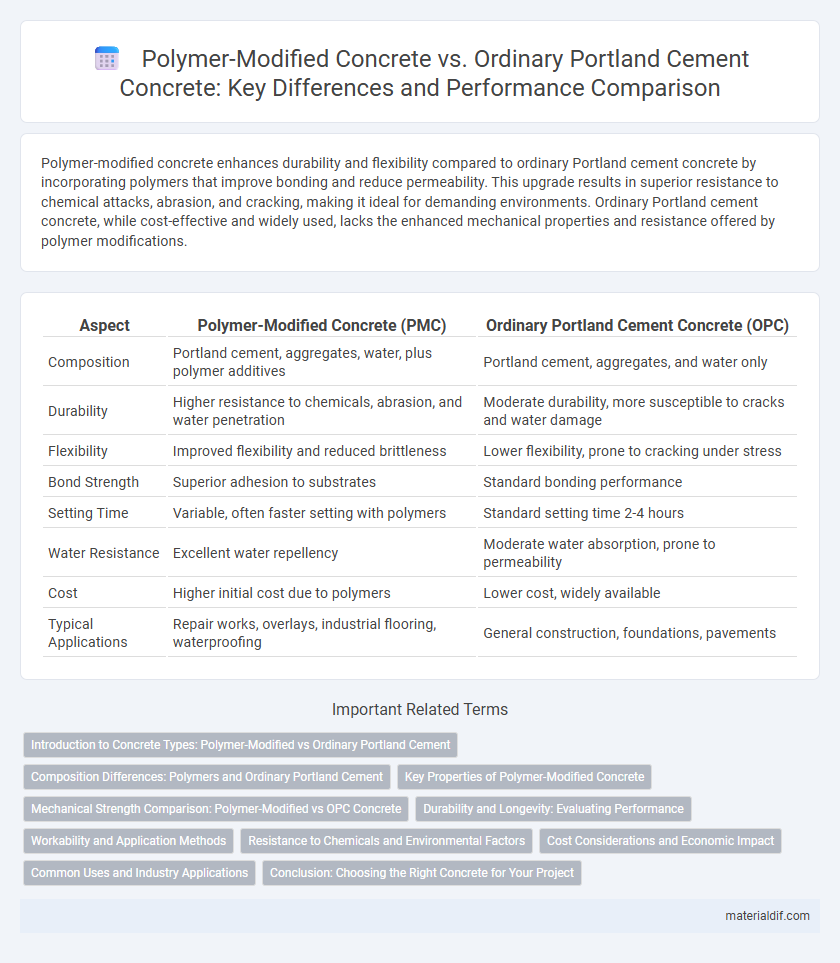

Table of Comparison

| Aspect | Polymer-Modified Concrete (PMC) | Ordinary Portland Cement Concrete (OPC) |

|---|---|---|

| Composition | Portland cement, aggregates, water, plus polymer additives | Portland cement, aggregates, and water only |

| Durability | Higher resistance to chemicals, abrasion, and water penetration | Moderate durability, more susceptible to cracks and water damage |

| Flexibility | Improved flexibility and reduced brittleness | Lower flexibility, prone to cracking under stress |

| Bond Strength | Superior adhesion to substrates | Standard bonding performance |

| Setting Time | Variable, often faster setting with polymers | Standard setting time 2-4 hours |

| Water Resistance | Excellent water repellency | Moderate water absorption, prone to permeability |

| Cost | Higher initial cost due to polymers | Lower cost, widely available |

| Typical Applications | Repair works, overlays, industrial flooring, waterproofing | General construction, foundations, pavements |

Introduction to Concrete Types: Polymer-Modified vs Ordinary Portland Cement

Polymer-modified concrete (PMC) incorporates polymers such as styrene-butadiene or acrylics to enhance properties like adhesion, flexibility, and chemical resistance compared to ordinary Portland cement concrete (OPC). OPC primarily relies on hydration of clinker minerals like tricalcium silicate to develop strength, making it cost-effective but less adaptable to aggressive environments. PMC offers improved durability in harsh chemical exposures and dynamic loading, making it suitable for specialized construction applications where OPC's performance may be limited.

Composition Differences: Polymers and Ordinary Portland Cement

Polymer-modified concrete (PMC) incorporates synthetic polymers such as styrene-butadiene rubber (SBR) or acrylics, which enhance adhesion, flexibility, and chemical resistance compared to Ordinary Portland Cement (OPC) concrete. OPC concrete primarily consists of clinker compounds like alite and belite, along with gypsum, creating a rigid matrix upon hydration. The inclusion of polymers in PMC alters the microstructure, resulting in improved tensile strength and reduced permeability relative to standard OPC concrete.

Key Properties of Polymer-Modified Concrete

Polymer-modified concrete (PMC) exhibits superior tensile strength, enhanced flexural strength, and improved adhesion compared to ordinary Portland cement concrete (OPC). The incorporation of polymers reduces porosity and increases resistance to chemical attacks, water penetration, and freeze-thaw cycles, significantly extending the durability of concrete structures. These key properties make PMC ideal for infrastructure exposed to harsh environmental conditions and heavy mechanical loads.

Mechanical Strength Comparison: Polymer-Modified vs OPC Concrete

Polymer-modified concrete (PMC) exhibits superior mechanical strength compared to ordinary Portland cement (OPC) concrete due to enhanced bonding and reduced porosity, resulting in increased compressive and tensile strength. Studies show PMC can improve flexural strength by up to 30% and compressive strength by approximately 15-20% over conventional OPC mixtures. This strength enhancement is attributed to the polymer film formed within the cement matrix, which improves microstructure and durability under mechanical stress.

Durability and Longevity: Evaluating Performance

Polymer-modified concrete demonstrates superior durability and longevity compared to ordinary Portland cement concrete due to its enhanced resistance to chemical attacks, moisture ingress, and freeze-thaw cycles. The incorporation of polymers improves the concrete's tensile strength and reduces permeability, effectively minimizing cracking and extending service life in aggressive environments. Studies indicate polymer-modified concrete can achieve lifespan extensions of up to 50% in infrastructure exposed to harsh conditions, making it a preferred choice for long-term performance.

Workability and Application Methods

Polymer-modified concrete exhibits superior workability compared to ordinary Portland cement concrete due to the inclusion of polymer additives that enhance flowability and reduce water demand. This improved workability allows for easier placement and better surface finishing, making it ideal for complex forms and thin overlays. Application methods for polymer-modified concrete often involve spraying or troweling, providing greater versatility in repair works and protective coatings compared to conventional mixing and pouring techniques used for ordinary Portland cement concrete.

Resistance to Chemicals and Environmental Factors

Polymer-modified concrete exhibits superior resistance to chemicals such as acids, sulfates, and chlorides compared to ordinary Portland cement concrete, making it ideal for harsh industrial environments. Its enhanced durability against freeze-thaw cycles, abrasion, and moisture ingress ensures longer service life and reduced maintenance costs. This improved chemical and environmental resilience stems from the polymer additives that reduce porosity and increase bonding within the concrete matrix.

Cost Considerations and Economic Impact

Polymer-modified concrete (PMC) typically incurs higher initial costs due to the expense of polymer additives compared to ordinary Portland cement (OPC) concrete, which relies on widely available cement and aggregates. Despite the upfront investment, PMC offers enhanced durability and reduced maintenance expenses, resulting in lower life-cycle costs and improved economic efficiency over time. Choosing PMC can lead to significant long-term savings in infrastructure projects, particularly where resistance to chemicals, abrasion, and weathering is critical.

Common Uses and Industry Applications

Polymer-modified concrete (PMC) is commonly used in applications requiring enhanced durability, chemical resistance, and flexibility, such as industrial flooring, bridge overlays, and waterproofing structures. Ordinary Portland Cement (OPC) concrete is widely applied in general construction projects like residential buildings, highways, and sidewalks due to its cost-effectiveness and adequate strength. The choice between PMC and OPC concrete is driven by project-specific requirements related to environmental exposure and mechanical performance.

Conclusion: Choosing the Right Concrete for Your Project

Polymer-modified concrete offers enhanced durability, improved bonding strength, and superior resistance to chemical attacks compared to ordinary Portland cement concrete, making it ideal for infrastructure exposed to harsh environments. Ordinary Portland cement concrete remains cost-effective and suitable for standard construction projects where extreme performance requirements are not critical. Selecting the right concrete depends on project-specific factors such as environmental exposure, structural demands, and budget constraints to ensure optimal performance and longevity.

Polymer-Modified Concrete vs Ordinary Portland Cement Concrete Infographic

materialdif.com

materialdif.com