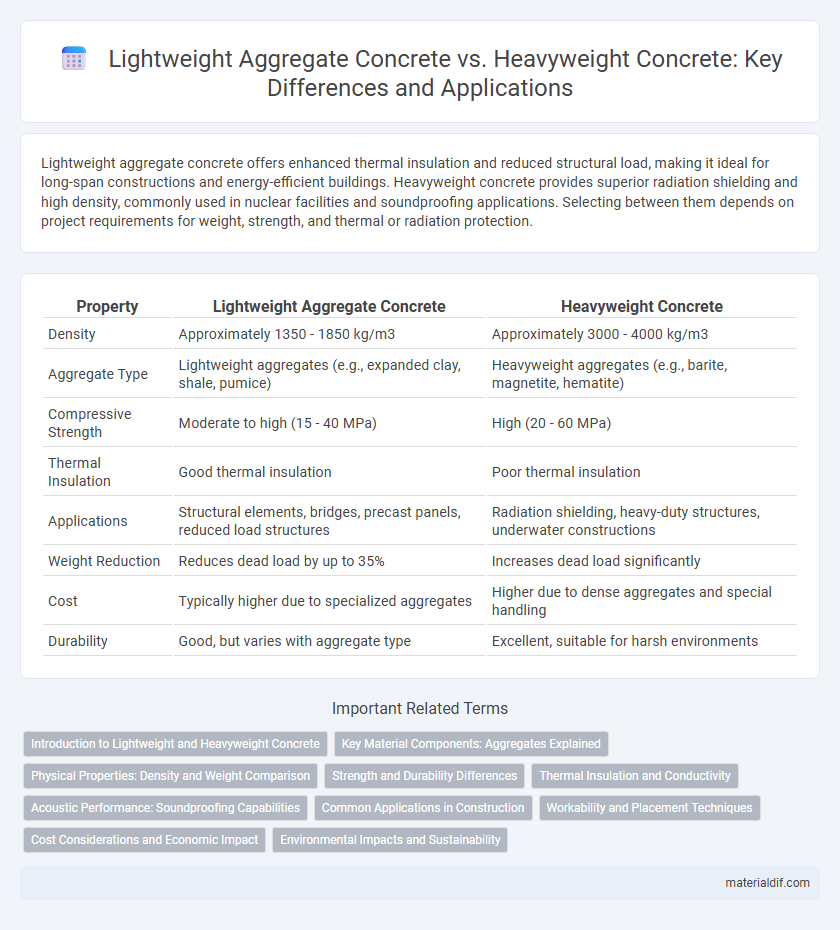

Lightweight aggregate concrete offers enhanced thermal insulation and reduced structural load, making it ideal for long-span constructions and energy-efficient buildings. Heavyweight concrete provides superior radiation shielding and high density, commonly used in nuclear facilities and soundproofing applications. Selecting between them depends on project requirements for weight, strength, and thermal or radiation protection.

Table of Comparison

| Property | Lightweight Aggregate Concrete | Heavyweight Concrete |

|---|---|---|

| Density | Approximately 1350 - 1850 kg/m3 | Approximately 3000 - 4000 kg/m3 |

| Aggregate Type | Lightweight aggregates (e.g., expanded clay, shale, pumice) | Heavyweight aggregates (e.g., barite, magnetite, hematite) |

| Compressive Strength | Moderate to high (15 - 40 MPa) | High (20 - 60 MPa) |

| Thermal Insulation | Good thermal insulation | Poor thermal insulation |

| Applications | Structural elements, bridges, precast panels, reduced load structures | Radiation shielding, heavy-duty structures, underwater constructions |

| Weight Reduction | Reduces dead load by up to 35% | Increases dead load significantly |

| Cost | Typically higher due to specialized aggregates | Higher due to dense aggregates and special handling |

| Durability | Good, but varies with aggregate type | Excellent, suitable for harsh environments |

Introduction to Lightweight and Heavyweight Concrete

Lightweight aggregate concrete utilizes aggregates such as expanded clay, shale, or pumice, resulting in a density ranging from 1,440 to 1,840 kg/m3, significantly reducing the dead load in structures. Heavyweight concrete incorporates dense aggregates like barytes, magnetite, or hematite, achieving densities up to 4,800 kg/m3, offering enhanced radiation shielding and improved impact resistance. These variations in aggregate types and densities directly influence the mechanical properties, thermal insulation, and application suitability of the concrete.

Key Material Components: Aggregates Explained

Lightweight aggregate concrete utilizes expanded clay, shale, or pumice aggregates that reduce density while maintaining strength, making it ideal for structural applications requiring lower self-weight. Heavyweight concrete incorporates dense aggregates like barite, magnetite, or hematite to significantly increase mass for radiation shielding and vibration damping. The choice of aggregate directly influences the concrete's weight, thermal properties, and mechanical performance.

Physical Properties: Density and Weight Comparison

Lightweight aggregate concrete exhibits densities typically ranging from 1,600 to 1,840 kg/m3, significantly lower than heavyweight concrete, which ranges from 2,400 to 3,800 kg/m3 due to the use of high-density aggregates like magnetite or hematite. The reduced density of lightweight concrete results in lower self-weight, enhancing structural efficiency and ease of handling in construction projects. Heavyweight concrete provides superior radiation shielding and impact resistance, making it suitable for specialized applications despite its increased weight and density.

Strength and Durability Differences

Lightweight aggregate concrete typically exhibits lower compressive strength compared to heavyweight concrete due to its porous aggregates, but it offers enhanced thermal insulation and reduced structural dead load. Heavyweight concrete, composed of dense aggregates like barite or magnetite, provides superior strength and exceptional radiation shielding, making it ideal for nuclear facilities and heavy-duty structures. Durability in heavyweight concrete is higher under aggressive environments, while lightweight concrete may require additional treatments to improve resistance to freeze-thaw cycles and abrasion.

Thermal Insulation and Conductivity

Lightweight aggregate concrete offers superior thermal insulation due to its lower density and higher porosity, reducing heat transfer compared to heavyweight concrete. Heavyweight concrete, characterized by higher density and mass, exhibits greater thermal conductivity, making it less efficient for insulation but ideal for applications requiring radiation shielding. Choosing between these concretes depends on balancing thermal performance needs with structural and environmental requirements.

Acoustic Performance: Soundproofing Capabilities

Lightweight aggregate concrete typically offers superior acoustic performance due to its porous structure, which enhances sound absorption and reduces noise transmission. In contrast, heavyweight concrete, with its dense composition, excels at blocking sound through mass but may reflect more noise internally. Selecting between the two depends on specific soundproofing needs, balancing absorption and sound blocking for optimal acoustic outcomes.

Common Applications in Construction

Lightweight aggregate concrete is commonly used in building facades, precast panels, and bridge decks due to its reduced density, which improves structural efficiency and thermal insulation. Heavyweight concrete is typically applied in radiation shielding for medical and nuclear facilities and in massive foundation works where high density provides enhanced strength and durability. Both materials meet specific engineering requirements, with lightweight concrete optimizing load reduction and heavyweight concrete ensuring resistance to impact and radiation.

Workability and Placement Techniques

Lightweight aggregate concrete offers enhanced workability due to its lower density and improved water retention, facilitating easier mixing and placement. Heavyweight concrete, characterized by its higher density and specialized aggregates, requires precise handling and vibration techniques to ensure proper compaction and avoid segregation. Optimizing placement methods such as pumping and formwork adjustments is crucial for maintaining quality in both lightweight and heavyweight concrete applications.

Cost Considerations and Economic Impact

Lightweight aggregate concrete generally offers cost savings through reduced transportation and handling expenses due to its lower density compared to heavyweight concrete, while heavyweight concrete incurs higher material costs from dense aggregates such as barite or magnetite. The economic impact of lightweight concrete includes potential reductions in structural support requirements and foundation costs, directly influencing overall project budgets. Heavyweight concrete is often selected for specialized applications requiring radiation shielding or high mass, which can justify its higher initial costs through long-term functional benefits.

Environmental Impacts and Sustainability

Lightweight aggregate concrete reduces environmental impact by utilizing recycled materials such as expanded clay, shale, or slate, which lower the overall carbon footprint and enhance energy efficiency in construction. Heavyweight concrete, often produced with dense aggregates like barite or magnetite, involves higher resource extraction and energy consumption, leading to greater environmental degradation. Sustainability in concrete production benefits from lightweight aggregate concrete's ability to improve thermal insulation and reduce structural load, contributing to long-term energy savings and reduced greenhouse gas emissions.

Lightweight Aggregate Concrete vs Heavyweight Concrete Infographic

materialdif.com

materialdif.com