Polymer-modified concrete enhances the durability and flexibility of traditional concrete by incorporating synthetic polymers, which improve adhesion, reduce permeability, and increase resistance to chemicals and weathering. Unlike traditional concrete, which primarily relies on cement and aggregates, polymer-modified concrete exhibits superior tensile strength and crack resistance, making it ideal for pavements and repair works. This advanced formulation extends the lifespan of concrete structures and reduces maintenance costs in harsh environments.

Table of Comparison

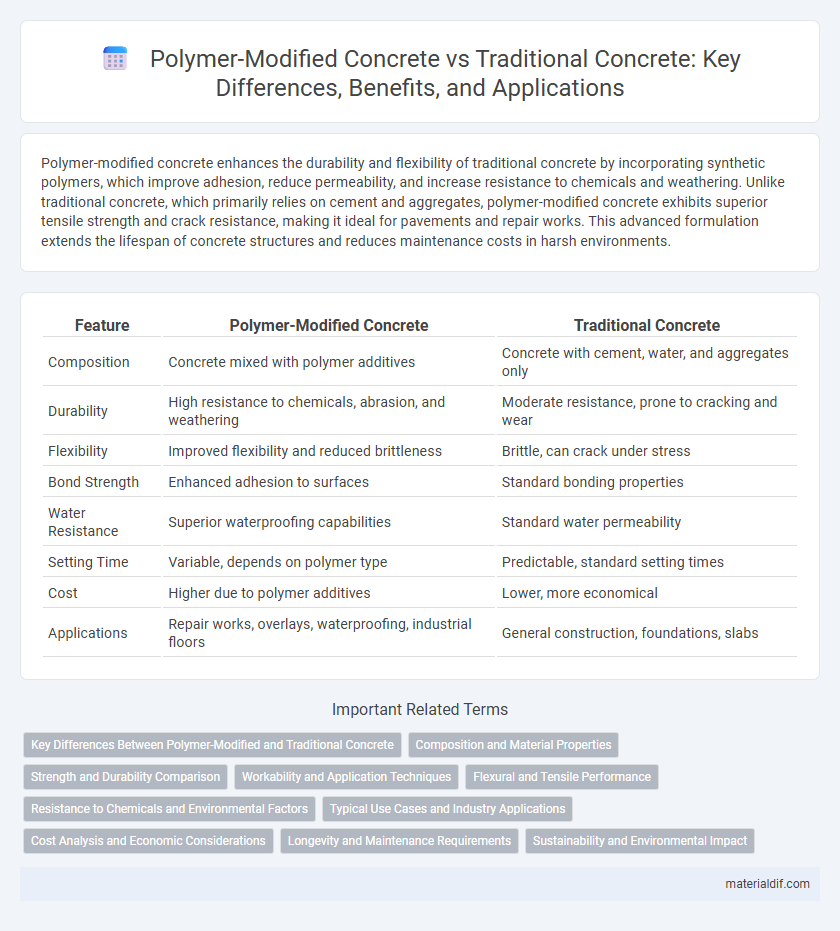

| Feature | Polymer-Modified Concrete | Traditional Concrete |

|---|---|---|

| Composition | Concrete mixed with polymer additives | Concrete with cement, water, and aggregates only |

| Durability | High resistance to chemicals, abrasion, and weathering | Moderate resistance, prone to cracking and wear |

| Flexibility | Improved flexibility and reduced brittleness | Brittle, can crack under stress |

| Bond Strength | Enhanced adhesion to surfaces | Standard bonding properties |

| Water Resistance | Superior waterproofing capabilities | Standard water permeability |

| Setting Time | Variable, depends on polymer type | Predictable, standard setting times |

| Cost | Higher due to polymer additives | Lower, more economical |

| Applications | Repair works, overlays, waterproofing, industrial floors | General construction, foundations, slabs |

Key Differences Between Polymer-Modified and Traditional Concrete

Polymer-modified concrete incorporates synthetic polymers, enhancing properties like adhesion, flexibility, and chemical resistance compared to traditional concrete, which relies solely on cement, water, and aggregates. These polymers improve performance in high-stress environments, offering superior durability, reduced permeability, and enhanced freeze-thaw resistance. Traditional concrete typically exhibits higher brittleness and lower tensile strength, making polymer-modified variants more suitable for specialized construction applications such as overlays, repairs, and chemical containment.

Composition and Material Properties

Polymer-modified concrete incorporates polymers such as styrene-butadiene rubber or acrylics into the cement matrix, enhancing its adhesion, flexibility, and resistance to chemical attack compared to traditional concrete. This modified composition reduces permeability and increases tensile strength, resulting in improved durability and reduced cracking under stress. Traditional concrete primarily relies on cement, aggregates, and water, offering good compressive strength but lower performance in terms of elasticity and resistance to environmental degradation.

Strength and Durability Comparison

Polymer-modified concrete exhibits significantly higher compressive and tensile strength compared to traditional concrete due to the incorporation of polymer resins that enhance the cementitious matrix. The polymer film improves bonding and reduces porosity, resulting in superior durability, chemical resistance, and reduced water permeability. Consequently, polymer-modified concrete offers enhanced performance in aggressive environments and applications requiring long-term structural integrity.

Workability and Application Techniques

Polymer-modified concrete offers enhanced workability due to improved flow characteristics and reduced segregation compared to traditional concrete. The presence of polymers increases adhesion and flexibility, allowing for easier placement and finishing in complex applications such as overlays and repairs. Traditional concrete typically requires more water and vibration for proper compaction, whereas polymer-modified mixes enable more efficient techniques with better durability outcomes.

Flexural and Tensile Performance

Polymer-modified concrete exhibits superior flexural and tensile strength compared to traditional concrete due to the incorporation of polymer resins that enhance bonding and reduce micro-cracking. This improvement results in greater resistance to bending stresses and improved durability in tensile applications, making it ideal for structural components subjected to dynamic loads. Studies show that polymer-modified concrete can increase flexural strength by up to 50% and significantly improve tensile capacity, extending the lifespan of concrete structures.

Resistance to Chemicals and Environmental Factors

Polymer-modified concrete exhibits superior resistance to chemicals and environmental factors compared to traditional concrete due to its enhanced polymer matrix that reduces permeability and increases durability. The integration of polymers improves resistance to acids, sulfates, and chlorides, making it ideal for harsh industrial environments and marine applications. Traditional concrete often suffers from chemical attack and surface degradation, leading to reduced lifespan and increased maintenance requirements.

Typical Use Cases and Industry Applications

Polymer-modified concrete is widely used in repair works, industrial flooring, and structures exposed to chemicals due to its enhanced durability, adhesion, and resistance to water and chemicals. Traditional concrete remains the preferred choice for large-scale infrastructure projects such as highways, bridges, and residential buildings where cost efficiency and compressive strength are critical. The construction industry often selects polymer-modified concrete for specialized applications requiring superior bonding and flexibility, while traditional concrete dominates in standard, high-load-bearing scenarios.

Cost Analysis and Economic Considerations

Polymer-modified concrete (PMC) generally entails higher initial costs compared to traditional concrete due to the expense of polymer additives, which can increase material prices by 20-40%. Despite the upfront investment, PMC often provides superior durability, reduced maintenance costs, and longer service life, resulting in lower total lifecycle costs over time. Economic considerations favor PMC in infrastructure projects exposed to harsh environments, where enhanced performance justifies the premium through savings on repairs and extended replacement intervals.

Longevity and Maintenance Requirements

Polymer-modified concrete exhibits significantly enhanced longevity compared to traditional concrete due to its superior resistance to cracking, chemical attack, and freeze-thaw cycles. Maintenance requirements for polymer-modified concrete are substantially lower because its improved durability reduces the frequency of repairs and surface treatments. In contrast, traditional concrete often demands more frequent maintenance to address issues like spalling and surface degradation.

Sustainability and Environmental Impact

Polymer-modified concrete enhances sustainability by improving durability and reducing maintenance frequency, leading to lower material consumption over its lifespan compared to traditional concrete. Its reduced permeability minimizes water ingress and chemical attack, decreasing the need for repair and the associated carbon emissions. Traditional concrete, while widely used, typically exhibits higher porosity and susceptibility to damage, which can result in increased resource use and environmental impact over time.

Polymer-Modified Concrete vs Traditional Concrete Infographic

materialdif.com

materialdif.com