Sulphate-resistant concrete is specifically designed to withstand harsh sulfate environments by using sulfate-resisting cement, which reduces the risk of chemical attack and deterioration compared to ordinary Portland cement. This type of concrete exhibits enhanced durability in sewage treatment plants, marine structures, and soil with high sulfate content. Ordinary Portland concrete tends to deteriorate faster in these conditions due to the formation of expansive compounds that cause cracking and loss of strength.

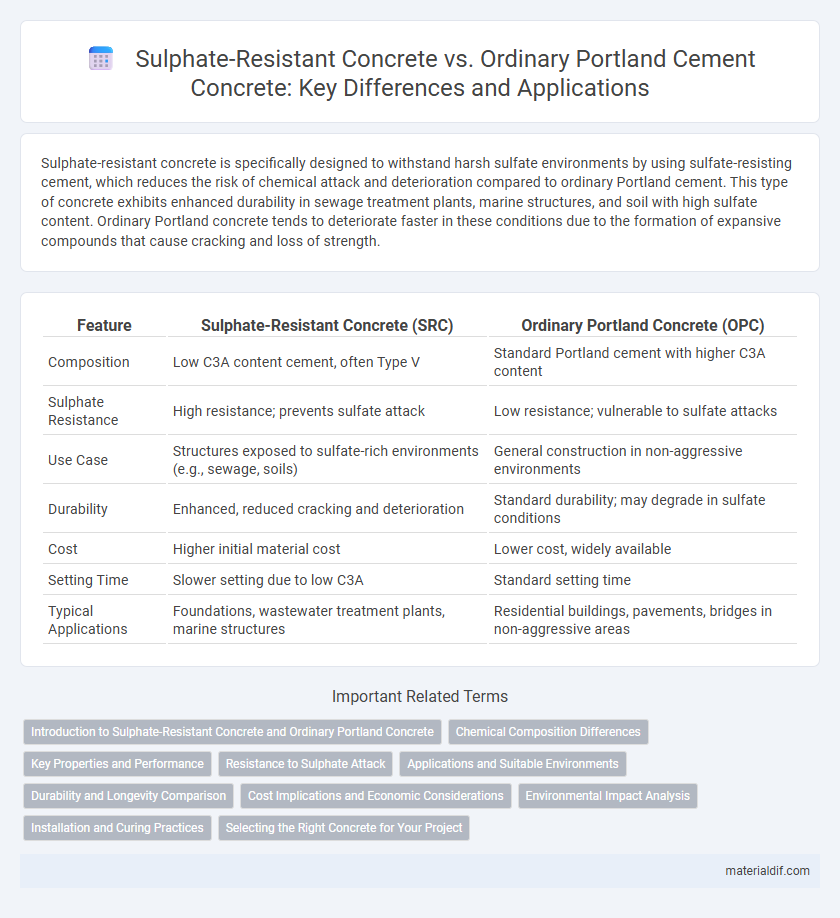

Table of Comparison

| Feature | Sulphate-Resistant Concrete (SRC) | Ordinary Portland Concrete (OPC) |

|---|---|---|

| Composition | Low C3A content cement, often Type V | Standard Portland cement with higher C3A content |

| Sulphate Resistance | High resistance; prevents sulfate attack | Low resistance; vulnerable to sulfate attacks |

| Use Case | Structures exposed to sulfate-rich environments (e.g., sewage, soils) | General construction in non-aggressive environments |

| Durability | Enhanced, reduced cracking and deterioration | Standard durability; may degrade in sulfate conditions |

| Cost | Higher initial material cost | Lower cost, widely available |

| Setting Time | Slower setting due to low C3A | Standard setting time |

| Typical Applications | Foundations, wastewater treatment plants, marine structures | Residential buildings, pavements, bridges in non-aggressive areas |

Introduction to Sulphate-Resistant Concrete and Ordinary Portland Concrete

Sulphate-resistant concrete is specially formulated to resist damage from sulfate ions commonly found in soil and groundwater, making it ideal for structures exposed to aggressive environments. It typically contains a low percentage of tricalcium aluminate (C3A) in the cement, significantly reducing sulfate attack and enhancing durability compared to ordinary Portland cement (OPC). Ordinary Portland concrete, while versatile and widely used for general construction, is more susceptible to deterioration in sulfate-rich conditions, leading to potential structural failure over time.

Chemical Composition Differences

Sulphate-resistant concrete contains a higher proportion of tri-calcium aluminate (C3A) in its chemical composition, which is reduced to minimize reactivity with sulphates, unlike Ordinary Portland Cement (OPC) that has a higher C3A content making it more susceptible to sulphate attack. The lower C3A content in sulphate-resistant concrete reduces the formation of expansive products such as ettringite, enhancing durability in sulfate-rich environments. Additionally, slag and pozzolanic materials are commonly blended in sulphate-resistant concrete to further improve its chemical resistance compared to standard OPC.

Key Properties and Performance

Sulphate-resistant concrete features low tricalcium aluminate content, enhancing durability against sulphate attack by minimizing expansion and cracking in aggressive environments. Ordinary Portland concrete, with higher tricalcium aluminate levels, is more susceptible to sulphate-induced deterioration, leading to reduced lifespan in sulfate-rich soils or water. Sulphate-resistant concrete typically exhibits improved chemical stability, lower permeability, and superior resistance to sulfate ions, making it ideal for sewage treatment plants, marine structures, and foundations in sulfate-laden soils.

Resistance to Sulphate Attack

Sulphate-resistant concrete (SRC) is specifically formulated with low tricalcium aluminate content and supplementary cementitious materials like fly ash or slag to enhance resistance against sulphate attack in aggressive soil or groundwater environments. Ordinary Portland concrete (OPC) is more susceptible to sulphate-induced expansion and degradation due to its higher C3A content, leading to potential structural damage and reduced durability. SRC's improved chemical stability ensures longer lifespan and structural integrity in sulphate-rich conditions compared to OPC.

Applications and Suitable Environments

Sulphate-resistant concrete is ideal for construction in environments with high sulphate concentrations, such as sewage treatment plants, marine structures, and foundations in sulfate-rich soils, where ordinary Portland cement concrete would deteriorate rapidly. Ordinary Portland concrete suits general construction projects in dry, non-aggressive environments like buildings, pavements, and bridges with low exposure to sulphates. The choice between these concretes depends on the chemical exposure risks and the required durability for long-term structural integrity.

Durability and Longevity Comparison

Sulphate-resistant concrete demonstrates superior durability compared to ordinary Portland concrete due to its enhanced resistance to sulfate attack, which prevents expansive reactions that cause cracking and deterioration in aggressive soil or groundwater environments. This concrete type typically incorporates low C3A clinker or supplementary cementitious materials like fly ash, significantly extending the service life of structures exposed to sulfate-rich conditions. Ordinary Portland concrete, lacking these modifications, tends to experience reduced longevity in such environments, leading to increased maintenance costs and structural failures.

Cost Implications and Economic Considerations

Sulphate-resistant concrete generally incurs higher initial costs due to specialized cement materials and production processes but offers long-term economic benefits by reducing repair and maintenance expenses in sulfate-rich environments. Ordinary Portland concrete, while cheaper upfront, risks significant structural damage and costly rehabilitation when exposed to sulfates, leading to increased lifecycle expenses. Evaluating total cost of ownership favors sulphate-resistant concrete in aggressive sulfate conditions, making it a cost-effective solution for durability and infrastructure longevity.

Environmental Impact Analysis

Sulphate-resistant concrete reduces environmental impact by extending the lifespan of structures in sulphate-rich soils, minimizing the need for frequent repairs and reconstruction. Ordinary Portland cement contributes higher CO2 emissions during production due to its increased clinker content, exacerbating carbon footprints. Utilizing sulphate-resistant concrete supports sustainable construction by lowering greenhouse gas emissions and resource consumption over time.

Installation and Curing Practices

Sulphate-resistant concrete requires careful mixing with low heat of hydration cement and consistent moisture curing for at least 7 days to prevent premature cracking and ensure sulfate resistance. Ordinary Portland cement concrete typically allows for faster setting times but necessitates protection from rapid drying to avoid shrinkage and reduced strength. Proper curing methods, such as wet curing or curing compounds, are critical for both types to achieve optimal durability and performance in their respective applications.

Selecting the Right Concrete for Your Project

Sulphate-resistant concrete offers enhanced durability in environments with high sulphate concentrations, preventing chemical attacks that can degrade ordinary Portland cement. Selecting the right concrete depends on assessing soil and groundwater sulphate levels, project exposure conditions, and required lifespan to ensure structural integrity. Testing for sulphate content and consulting ASTM C150 Type V specifications helps engineers avoid premature deterioration and costly repairs.

Sulphate-Resistant Concrete vs Ordinary Portland Concrete Infographic

materialdif.com

materialdif.com