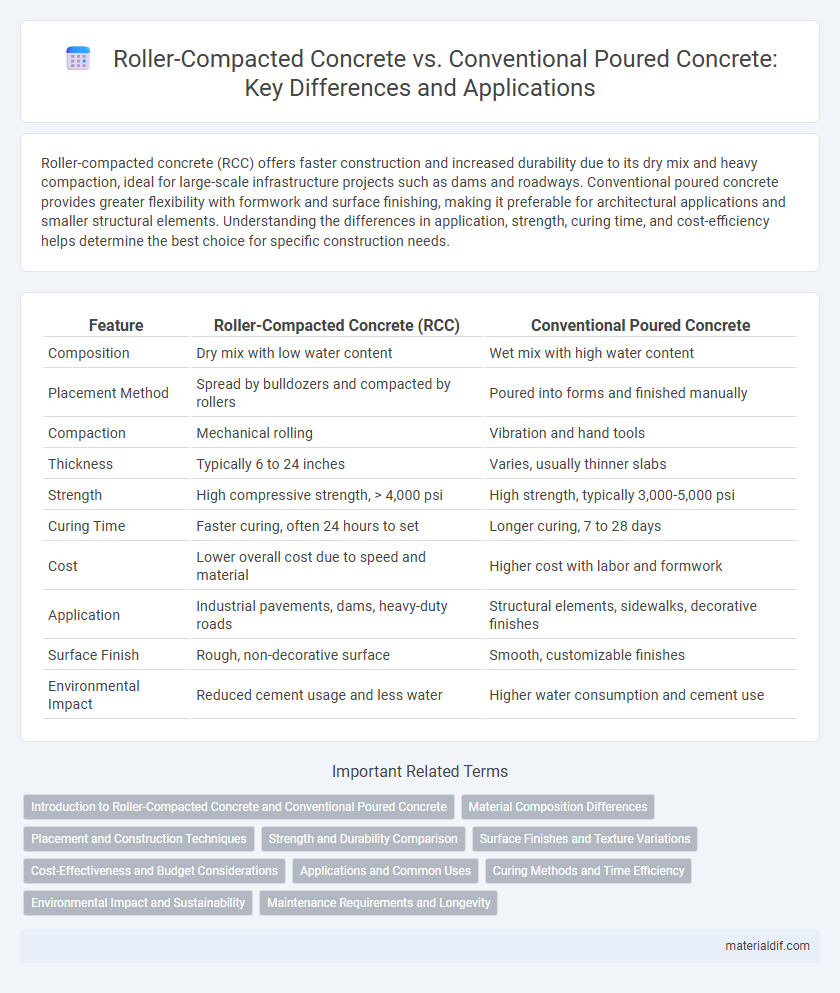

Roller-compacted concrete (RCC) offers faster construction and increased durability due to its dry mix and heavy compaction, ideal for large-scale infrastructure projects such as dams and roadways. Conventional poured concrete provides greater flexibility with formwork and surface finishing, making it preferable for architectural applications and smaller structural elements. Understanding the differences in application, strength, curing time, and cost-efficiency helps determine the best choice for specific construction needs.

Table of Comparison

| Feature | Roller-Compacted Concrete (RCC) | Conventional Poured Concrete |

|---|---|---|

| Composition | Dry mix with low water content | Wet mix with high water content |

| Placement Method | Spread by bulldozers and compacted by rollers | Poured into forms and finished manually |

| Compaction | Mechanical rolling | Vibration and hand tools |

| Thickness | Typically 6 to 24 inches | Varies, usually thinner slabs |

| Strength | High compressive strength, > 4,000 psi | High strength, typically 3,000-5,000 psi |

| Curing Time | Faster curing, often 24 hours to set | Longer curing, 7 to 28 days |

| Cost | Lower overall cost due to speed and material | Higher cost with labor and formwork |

| Application | Industrial pavements, dams, heavy-duty roads | Structural elements, sidewalks, decorative finishes |

| Surface Finish | Rough, non-decorative surface | Smooth, customizable finishes |

| Environmental Impact | Reduced cement usage and less water | Higher water consumption and cement use |

Introduction to Roller-Compacted Concrete and Conventional Poured Concrete

Roller-compacted concrete (RCC) is a dry mix concrete placed using asphalt paving equipment and compacted with vibratory rollers, offering rapid construction and high durability for large-scale infrastructure like dams and pavements. Conventional poured concrete involves a wet mix poured into forms, providing flexibility in shaping and finishing for structural elements such as beams, slabs, and columns. RCC's low slump consistency contrasts with the fluid nature of conventional concrete, influencing placement methods and application suitability.

Material Composition Differences

Roller-compacted concrete (RCC) features a drier mix with lower water content and a higher proportion of coarse aggregates compared to conventional poured concrete, resulting in a stiff, low-slump consistency ideal for layering with rollers. Conventional poured concrete typically includes more water, finer aggregates, and admixtures to achieve a fluid mixture suitable for forming and finishing. The reduced water-to-cement ratio in RCC enhances its density and compressive strength, while conventional concrete's higher workability allows for complex shapes and smooth surface finishes.

Placement and Construction Techniques

Roller-compacted concrete (RCC) is placed using heavy rollers that compact the concrete after it is spread, enabling faster construction and reduced labor compared to conventional poured concrete, which requires formwork, vibration, and finishing. RCC's dry, low-slump consistency allows for rapid placement in large volumes, ideal for pavements and dam construction, while conventional poured concrete demands careful placement, consolidation, and curing for structural integrity in buildings and complex forms. The construction techniques for RCC emphasize continuous layering and compaction, contrasting with the controlled pouring and finishing processes essential for traditional concrete applications.

Strength and Durability Comparison

Roller-compacted concrete (RCC) exhibits superior compressive strength and enhanced durability due to its low water-cement ratio and dense matrix, making it ideal for heavy-duty pavements and industrial floors. Conventional poured concrete offers more flexibility in mix design and finish but typically has lower strength and durability when exposed to high loads and harsh environmental conditions. Studies indicate RCC's homogenous structure reduces permeability and improves resistance to freeze-thaw cycles compared to traditional concrete.

Surface Finishes and Texture Variations

Roller-compacted concrete (RCC) typically exhibits a rougher, more textured surface finish due to its dry consistency and compaction process, making it ideal for heavy-duty pavement applications requiring high durability. In contrast, conventional poured concrete allows for smoother and more varied textures, including stamped, broom-finished, or exposed aggregate surfaces, providing greater aesthetic flexibility for architectural and decorative purposes. Surface finish choices directly impact slip resistance, visual appeal, and maintenance requirements in both RCC and conventional applications.

Cost-Effectiveness and Budget Considerations

Roller-compacted concrete (RCC) offers significant cost savings over conventional poured concrete by reducing material and labor expenses through faster placement and minimal formwork requirements. The compacting process of RCC allows for large-scale projects like dam construction and industrial pavements to meet tight budgets without sacrificing durability. Conventional poured concrete, while providing greater finish flexibility, often incurs higher costs due to extended curing times and more labor-intensive installation methods.

Applications and Common Uses

Roller-compacted concrete (RCC) is widely used for heavy-duty applications such as dam construction, industrial floors, and pavements due to its high durability and rapid placement. Conventional poured concrete is preferred for structural elements like beams, slabs, and columns where precise formwork and smooth finishes are essential. RCC's compacted stiffness suits large-scale infrastructure, while conventional concrete excels in architectural and detailed structural uses.

Curing Methods and Time Efficiency

Roller-Compacted Concrete (RCC) requires shorter curing times compared to conventional poured concrete due to its dry consistency and compaction method, typically allowing for faster strength gain within 24 to 48 hours. Conventional poured concrete curing involves maintaining moisture for 7 to 28 days to achieve optimal hydration and strength, which can slow construction schedules. RCC's accelerated curing process improves time efficiency, making it ideal for large-scale infrastructure projects like dams and pavements where rapid load application is critical.

Environmental Impact and Sustainability

Roller-compacted concrete (RCC) significantly reduces environmental impact by using less water and cement compared to conventional poured concrete, leading to lower carbon emissions during production. RCC's rapid placement and compaction reduce energy consumption on-site, enhancing sustainability through faster construction times and less machinery fuel usage. Additionally, RCC's durability and reduced maintenance needs contribute to a longer service life, minimizing resource consumption over the structure's lifespan.

Maintenance Requirements and Longevity

Roller-compacted concrete (RCC) requires less maintenance than conventional poured concrete due to its dense, low-permeability surface that resists cracking and erosion. RCC's high durability makes it ideal for heavy-duty applications like industrial floors and pavements, offering extended longevity compared to traditional poured concrete, which often demands periodic sealing and repair. The reduced maintenance frequency and superior resistance of RCC contribute to lower life-cycle costs and enhanced structural lifespan.

Roller-Compacted Concrete vs Conventional Poured Concrete Infographic

materialdif.com

materialdif.com