Precast concrete offers superior quality control and faster construction times due to factory production, while cast-in-place concrete provides greater flexibility for complex shapes and on-site adjustments. Precast elements reduce on-site labor and minimize weather-related delays, contrasting with cast-in-place methods that require formwork and curing time at the construction site. Choosing between precast and cast-in-place concrete depends on project requirements, timeline, budget, and design complexity.

Table of Comparison

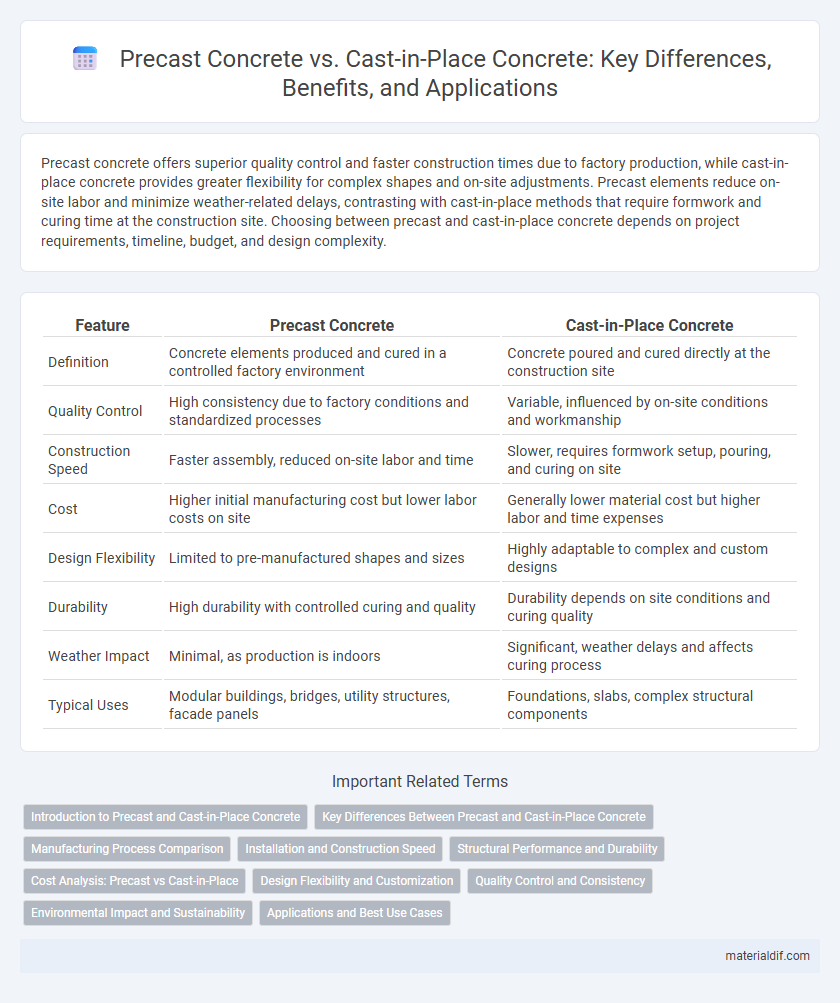

| Feature | Precast Concrete | Cast-in-Place Concrete |

|---|---|---|

| Definition | Concrete elements produced and cured in a controlled factory environment | Concrete poured and cured directly at the construction site |

| Quality Control | High consistency due to factory conditions and standardized processes | Variable, influenced by on-site conditions and workmanship |

| Construction Speed | Faster assembly, reduced on-site labor and time | Slower, requires formwork setup, pouring, and curing on site |

| Cost | Higher initial manufacturing cost but lower labor costs on site | Generally lower material cost but higher labor and time expenses |

| Design Flexibility | Limited to pre-manufactured shapes and sizes | Highly adaptable to complex and custom designs |

| Durability | High durability with controlled curing and quality | Durability depends on site conditions and curing quality |

| Weather Impact | Minimal, as production is indoors | Significant, weather delays and affects curing process |

| Typical Uses | Modular buildings, bridges, utility structures, facade panels | Foundations, slabs, complex structural components |

Introduction to Precast and Cast-in-Place Concrete

Precast concrete refers to concrete components that are cast and cured in a controlled factory environment, allowing for high-quality finishes and consistent structural performance. Cast-in-place concrete, also known as in-situ concrete, is poured and cured directly on the construction site, offering flexibility in design and adaptability to complex architectural forms. Both methods are essential in modern construction, with precast concrete providing faster installation and reduced labor costs, while cast-in-place concrete allows for customized shapes and seamless integration with existing structures.

Key Differences Between Precast and Cast-in-Place Concrete

Precast concrete is manufactured in a controlled factory environment, offering higher quality control and faster installation compared to cast-in-place concrete, which is poured and cured directly on the construction site. Cast-in-place concrete allows for greater flexibility in design and is ideal for complex, custom-shaped structures, while precast components are limited to standard molds and require transportation logistics. The curing time for cast-in-place concrete typically extends project timelines, whereas precast concrete accelerates construction schedules through simultaneous off-site production and on-site preparation.

Manufacturing Process Comparison

Precast concrete is manufactured in a controlled factory environment, allowing for precise mixing, curing, and quality control before transportation to the construction site. Cast-in-place concrete is mixed and poured directly on-site, requiring formwork setup, manual finishing, and longer curing times influenced by weather conditions. The factory setting of precast concrete results in faster installation and consistent structural performance compared to the variability of cast-in-place methods.

Installation and Construction Speed

Precast concrete components are manufactured off-site under controlled conditions, enabling rapid on-site assembly and significantly reducing overall construction time. Cast-in-place concrete requires on-site formwork, pouring, and curing, which extends installation time and is more weather-dependent. Projects utilizing precast concrete often benefit from accelerated schedules and decreased labor costs compared to cast-in-place methods.

Structural Performance and Durability

Precast concrete offers superior structural performance due to its factory-controlled fabrication, ensuring consistent strength and reduced defects compared to cast-in-place concrete. Its enhanced durability results from optimal curing conditions, minimizing permeability and increasing resistance to environmental factors such as freeze-thaw cycles and chemical exposure. Cast-in-place concrete provides flexibility in design and onsite adjustments but may experience variability in strength and durability due to site conditions and curing inconsistencies.

Cost Analysis: Precast vs Cast-in-Place

Precast concrete typically reduces labor costs due to factory-controlled production and faster on-site assembly, while cast-in-place concrete often incurs higher labor expenses from extended curing times and on-site formwork. Material costs can be lower in cast-in-place projects because of local sourcing, but the increased time and labor can offset these savings. Overall, precast concrete offers cost advantages in large-scale or repetitive projects through streamlined production and minimized site disruption.

Design Flexibility and Customization

Precast concrete offers limited design flexibility due to its factory-controlled production and standardized molds, making it ideal for repetitive, modular structures. Cast-in-place concrete provides superior customization options, allowing architects and engineers to create complex shapes and unique architectural features on-site. This adaptability makes cast-in-place concrete preferred for projects requiring intricate design details and bespoke construction elements.

Quality Control and Consistency

Precast concrete offers superior quality control and consistency due to its production in a controlled factory environment, allowing for precise mixing, molding, and curing processes. Cast-in-place concrete often faces variability from onsite conditions such as weather, mixing methods, and workmanship, which can affect the final strength and durability. The uniformity of precast elements reduces the risk of defects, ensuring reliable performance in structural applications.

Environmental Impact and Sustainability

Precast concrete significantly reduces environmental impact by minimizing on-site waste and enabling precise material use through factory-controlled production. Cast-in-place concrete often involves higher energy consumption and greenhouse gas emissions due to extended curing times and transportation of raw materials to the site. Utilizing precast concrete enhances sustainability by promoting recycling of concrete components and reducing construction timelines, thereby lowering overall carbon footprints.

Applications and Best Use Cases

Precast concrete is ideal for repetitive, large-scale projects like bridges, parking structures, and modular building components due to its factory-controlled quality and faster installation times. Cast-in-place concrete excels in custom, complex designs such as foundations, slabs, and structures requiring on-site customization or unique shapes. Selecting between precast and cast-in-place concrete depends on project scale, design complexity, construction timeline, and site accessibility.

Precast Concrete vs Cast-in-Place Concrete Infographic

materialdif.com

materialdif.com