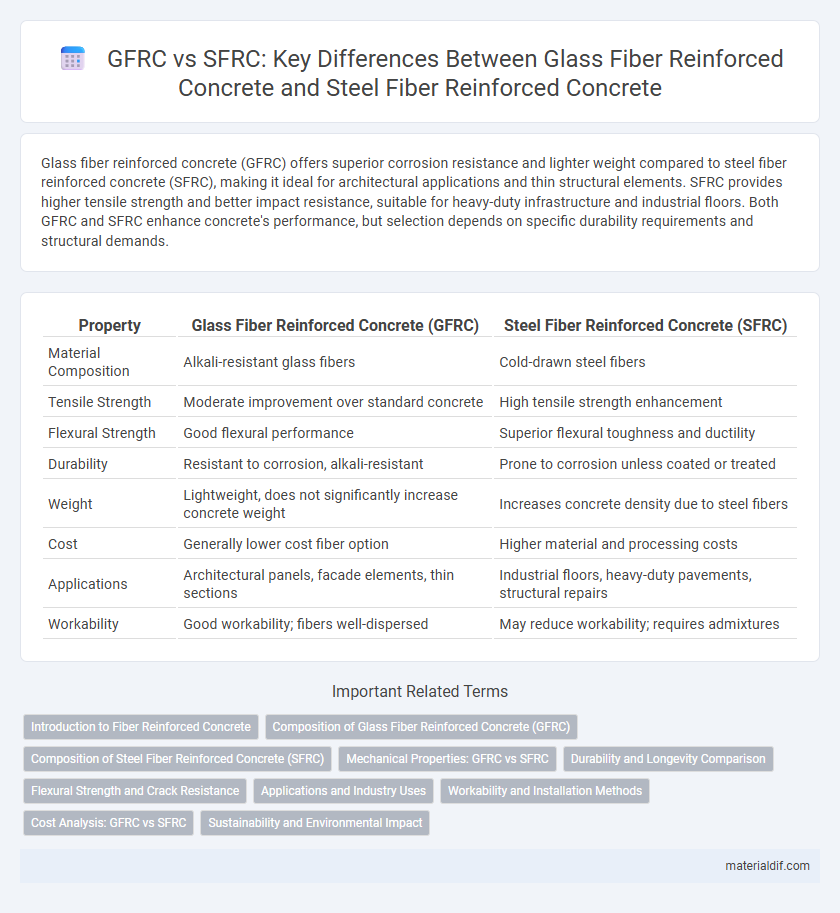

Glass fiber reinforced concrete (GFRC) offers superior corrosion resistance and lighter weight compared to steel fiber reinforced concrete (SFRC), making it ideal for architectural applications and thin structural elements. SFRC provides higher tensile strength and better impact resistance, suitable for heavy-duty infrastructure and industrial floors. Both GFRC and SFRC enhance concrete's performance, but selection depends on specific durability requirements and structural demands.

Table of Comparison

| Property | Glass Fiber Reinforced Concrete (GFRC) | Steel Fiber Reinforced Concrete (SFRC) |

|---|---|---|

| Material Composition | Alkali-resistant glass fibers | Cold-drawn steel fibers |

| Tensile Strength | Moderate improvement over standard concrete | High tensile strength enhancement |

| Flexural Strength | Good flexural performance | Superior flexural toughness and ductility |

| Durability | Resistant to corrosion, alkali-resistant | Prone to corrosion unless coated or treated |

| Weight | Lightweight, does not significantly increase concrete weight | Increases concrete density due to steel fibers |

| Cost | Generally lower cost fiber option | Higher material and processing costs |

| Applications | Architectural panels, facade elements, thin sections | Industrial floors, heavy-duty pavements, structural repairs |

| Workability | Good workability; fibers well-dispersed | May reduce workability; requires admixtures |

Introduction to Fiber Reinforced Concrete

Fiber reinforced concrete (FRC) enhances traditional concrete by incorporating fibers to improve tensile strength, crack resistance, and durability. Glass fiber reinforced concrete (GFRC) uses alkali-resistant glass fibers, offering lightweight properties and excellent corrosion resistance, making it ideal for architectural panels and facade elements. Steel fiber reinforced concrete (SFRC) contains steel fibers that provide superior toughness, impact resistance, and load-bearing capacity, commonly used in industrial floors, highways, and structural components.

Composition of Glass Fiber Reinforced Concrete (GFRC)

Glass Fiber Reinforced Concrete (GFRC) consists primarily of a cementitious matrix combined with alkali-resistant glass fibers, typically ranging from 0.5% to 5% by volume for optimal performance. These glass fibers measure between 12 to 18 microns in diameter and are specifically engineered to resist alkaline degradation within the concrete matrix. The composition also includes fine aggregates and various admixtures that enhance workability, durability, and bonding between fibers and the cement paste.

Composition of Steel Fiber Reinforced Concrete (SFRC)

Steel Fiber Reinforced Concrete (SFRC) is composed of a traditional concrete mix integrated with discrete steel fibers, typically ranging from 0.5% to 2.0% by volume. These steel fibers, often made of carbon or stainless steel, vary in length and diameter, enhancing tensile strength, crack resistance, and impact durability. The matrix includes cement, aggregates, water, and admixtures, optimized to ensure proper fiber dispersion and bond within the concrete.

Mechanical Properties: GFRC vs SFRC

Glass fiber reinforced concrete (GFRC) exhibits excellent tensile strength and improved crack resistance due to the high modulus of elasticity of glass fibers, making it suitable for architectural panels and thin sections. Steel fiber reinforced concrete (SFRC) offers superior flexural strength, impact resistance, and toughness, attributed to the ductile nature of steel fibers, enhancing structural performance in heavy-load applications. Both GFRC and SFRC improve concrete's mechanical properties, but GFRC excels in lightweight, corrosion-resistant environments, while SFRC is preferred for durability and load-bearing capacity.

Durability and Longevity Comparison

Glass fiber reinforced concrete (GFRC) offers excellent resistance to corrosion and chemical attack, making it highly durable in harsh environments. Steel fiber reinforced concrete (SFRC) provides superior toughness and crack control, extending structural longevity under heavy load and impact conditions. GFRC's lightweight nature reduces stress on structures, while SFRC's metal fibers contribute to enhanced fatigue resistance and long-term stability.

Flexural Strength and Crack Resistance

Glass fiber reinforced concrete (GFRC) exhibits high flexural strength due to the fine glass fibers that distribute tensile loads efficiently, enhancing resistance to bending stresses. Steel fiber reinforced concrete (SFRC) demonstrates superior crack resistance with its ductile steel fibers that bridge cracks and inhibit crack propagation under tensile and flexural loading. Comparative studies show SFRC generally outperforms GFRC in crack control, while GFRC offers improved flexural strength-to-weight ratio and corrosion resistance in aggressive environments.

Applications and Industry Uses

Glass fiber reinforced concrete (GFRC) is widely used in architectural panels, facade cladding, and decorative elements due to its lightweight and high tensile strength, making it ideal for intricate and thin designs. Steel fiber reinforced concrete (SFRC) finds extensive application in industrial floors, bridges, tunnels, and precast elements because of its superior impact resistance, toughness, and load-bearing capacity. Both materials enhance durability and crack control but are selected based on specific industry needs--GFRC for aesthetic and lightweight structural components, SFRC for heavy-duty infrastructure requiring enhanced mechanical performance.

Workability and Installation Methods

Glass fiber reinforced concrete (GFRC) offers superior workability due to its lightweight fibers that enhance mix flexibility and ease of placing, making it ideal for intricate architectural designs. Steel fiber reinforced concrete (SFRC) exhibits reduced workability because steel fibers increase mix stiffness, requiring specialized vibration techniques to ensure proper consolidation. Installation of GFRC often employs spraying or casting methods, while SFRC typically utilizes conventional pouring and mechanical compaction to accommodate the heavier fiber content.

Cost Analysis: GFRC vs SFRC

Glass fiber reinforced concrete (GFRC) generally offers lower material and production costs compared to steel fiber reinforced concrete (SFRC) due to the less expensive and corrosion-resistant glass fibers. Steel fibers provide superior tensile strength and impact resistance but often result in higher overall expenses from raw materials and maintenance. The choice between GFRC and SFRC should consider budget constraints, performance requirements, and lifecycle costs.

Sustainability and Environmental Impact

Glass fiber reinforced concrete (GFRC) offers superior sustainability benefits compared to steel fiber reinforced concrete (SFRC) due to its lower embodied energy and recyclability of glass fibers. GFRC utilizes recycled glass content, reducing landfill waste and lowering carbon emissions associated with raw material extraction and processing. In contrast, SFRC relies on steel fibers that require energy-intensive steel production, resulting in higher environmental impact and less potential for eco-friendly disposal or recycling.

Glass fiber reinforced concrete (GFRC) vs steel fiber reinforced concrete (SFRC) Infographic

materialdif.com

materialdif.com