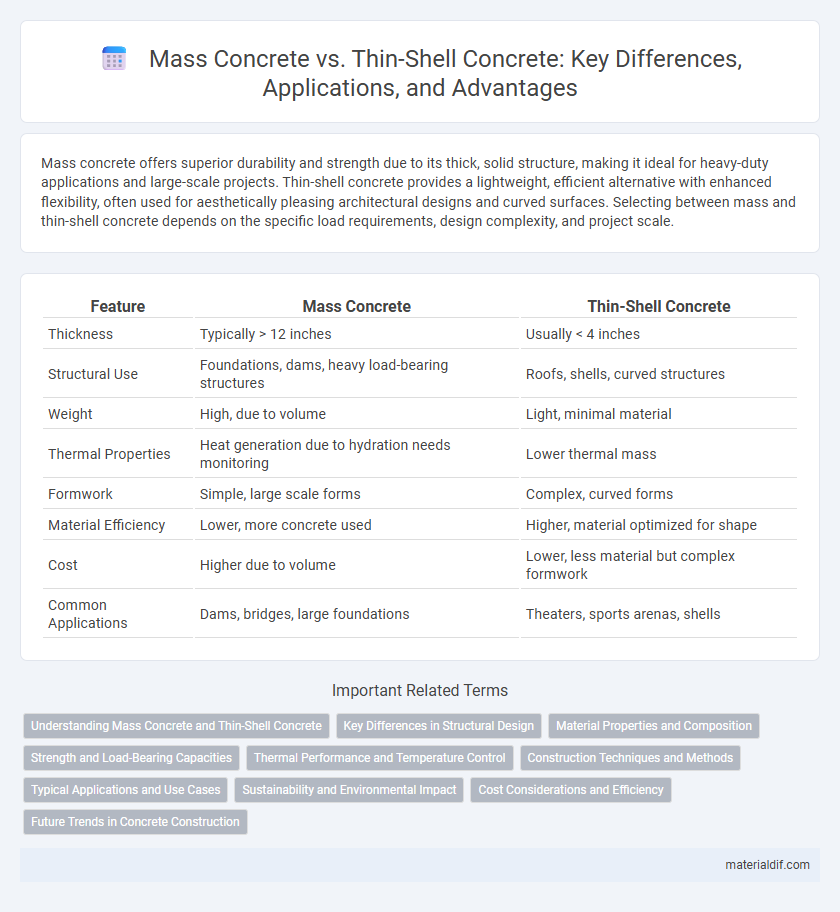

Mass concrete offers superior durability and strength due to its thick, solid structure, making it ideal for heavy-duty applications and large-scale projects. Thin-shell concrete provides a lightweight, efficient alternative with enhanced flexibility, often used for aesthetically pleasing architectural designs and curved surfaces. Selecting between mass and thin-shell concrete depends on the specific load requirements, design complexity, and project scale.

Table of Comparison

| Feature | Mass Concrete | Thin-Shell Concrete |

|---|---|---|

| Thickness | Typically > 12 inches | Usually < 4 inches |

| Structural Use | Foundations, dams, heavy load-bearing structures | Roofs, shells, curved structures |

| Weight | High, due to volume | Light, minimal material |

| Thermal Properties | Heat generation due to hydration needs monitoring | Lower thermal mass |

| Formwork | Simple, large scale forms | Complex, curved forms |

| Material Efficiency | Lower, more concrete used | Higher, material optimized for shape |

| Cost | Higher due to volume | Lower, less material but complex formwork |

| Common Applications | Dams, bridges, large foundations | Theaters, sports arenas, shells |

Understanding Mass Concrete and Thin-Shell Concrete

Mass concrete involves large volumes of concrete poured in a single placement, designed to resist significant structural loads and reduce thermal stresses during curing. Thin-shell concrete uses a curved, slender form to provide high strength with minimal material, optimizing structural efficiency through geometric shape. Understanding the differences between these types helps engineers select the appropriate method for each project's load-bearing and design requirements.

Key Differences in Structural Design

Mass concrete features a thick, heavy structure designed to withstand compression and thermal stresses, often used in dams and foundations for its durability and strength. Thin-shell concrete employs a lightweight, curved form that efficiently distributes loads through membrane action, minimizing material usage while maximizing strength. The key structural design difference lies in mass concrete's reliance on bulk and thickness to resist forces versus thin-shell concrete's optimization of shape and geometry for load-bearing capacity.

Material Properties and Composition

Mass concrete exhibits higher thermal conductivity and greater density due to its thick cross-section and substantial cement content, which leads to slower heat dissipation and potential thermal cracking risks. Thin-shell concrete, characterized by a reduced thickness and often reinforced with fibers or mesh, demonstrates enhanced tensile strength, flexibility, and reduced self-weight, making it suitable for complex, curved structures. The composition of mass concrete typically involves a higher aggregate-to-cement ratio to improve thermal stability, whereas thin-shell concrete incorporates admixtures and finer aggregates to increase workability and durability.

Strength and Load-Bearing Capacities

Mass concrete exhibits high compressive strength and superior load-bearing capacity due to its substantial volume and density, making it ideal for foundations and large structural elements. Thin-shell concrete structures leverage their curved geometry to efficiently distribute stresses, enabling them to carry significant loads despite their reduced thickness. Structural engineers must evaluate the trade-offs between mass concrete's durability and thin-shell designs' material efficiency when optimizing for strength and load-bearing performance.

Thermal Performance and Temperature Control

Mass concrete exhibits superior thermal stability due to its large volume and slow temperature changes, effectively minimizing thermal gradients and reducing the risk of cracking. Thin-shell concrete, with its slender profile, experiences rapid temperature fluctuations that require precise temperature control measures, such as cooling pipes or insulation, to prevent thermal stress. Optimizing thermal performance in mass concrete involves managing heat of hydration and curing processes, whereas thin-shell structures demand advanced monitoring and rapid response systems to maintain structural integrity.

Construction Techniques and Methods

Mass concrete construction relies on large volumes of untreated concrete poured in place, requiring careful control of heat generation and curing to prevent thermal cracking, often using layered pours and cooling pipes. Thin-shell concrete employs lightweight formwork and high-strength concrete to create curved, thin structures with minimal material use, utilizing advanced reinforcement and precision casting methods. The construction technique for mass concrete emphasizes bulk stability and thermal management, whereas thin-shell concrete focuses on geometric complexity and structural efficiency.

Typical Applications and Use Cases

Mass concrete is typically used in large-scale infrastructure projects such as dams, foundations, and retaining walls where its high thermal mass helps control heat generation during curing. Thin-shell concrete finds common applications in lightweight architectural structures, roofs, and domes due to its ability to span large areas with minimal material thickness. The choice between mass and thin-shell concrete depends largely on structural requirements, load-bearing capacity, and design aesthetics.

Sustainability and Environmental Impact

Mass concrete structures typically have a larger carbon footprint due to the extensive use of cement and formwork materials, leading to higher embodied energy and increased CO2 emissions. Thin-shell concrete designs optimize material efficiency by using less concrete while maintaining structural integrity, significantly reducing resource consumption and waste generation. The durability and thermal mass properties of thin-shell concrete further enhance sustainability by lowering energy needs for heating and cooling over the building's lifespan.

Cost Considerations and Efficiency

Mass concrete requires significantly more material volume and extended curing times, leading to higher initial costs and increased labor expenses compared to thin-shell concrete. Thin-shell concrete designs optimize material use by employing thinner sections with curved shapes, enhancing structural efficiency while reducing both material costs and construction duration. Efficient load distribution in thin-shell concrete minimizes reinforcement needs, further lowering overall project expenditure.

Future Trends in Concrete Construction

Future trends in concrete construction emphasize advancements in mass concrete and thin-shell concrete technologies, leveraging eco-friendly materials and digital modeling for enhanced structural performance. Innovations in mix design and curing methods are improving the durability and sustainability of mass concrete, while thin-shell concrete benefits from 3D printing and parametric design to create lightweight, efficient forms. Integration of smart sensors and real-time monitoring systems is transforming both mass and thin-shell concrete applications, driving smarter, more resilient infrastructure development.

Mass Concrete vs Thin-Shell Concrete Infographic

materialdif.com

materialdif.com