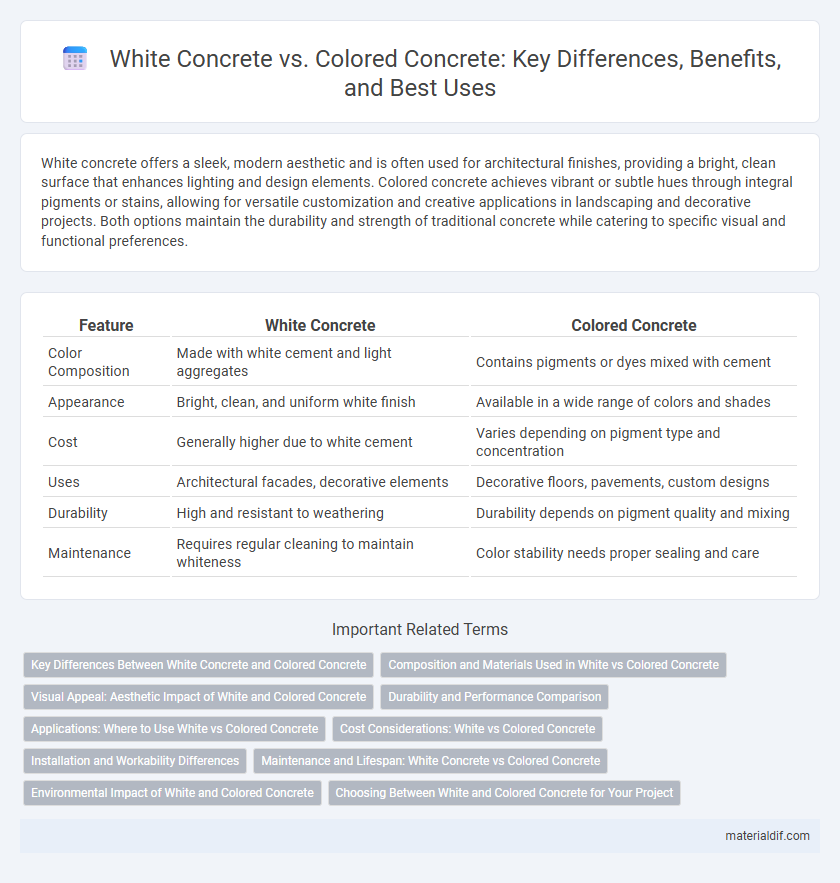

White concrete offers a sleek, modern aesthetic and is often used for architectural finishes, providing a bright, clean surface that enhances lighting and design elements. Colored concrete achieves vibrant or subtle hues through integral pigments or stains, allowing for versatile customization and creative applications in landscaping and decorative projects. Both options maintain the durability and strength of traditional concrete while catering to specific visual and functional preferences.

Table of Comparison

| Feature | White Concrete | Colored Concrete |

|---|---|---|

| Color Composition | Made with white cement and light aggregates | Contains pigments or dyes mixed with cement |

| Appearance | Bright, clean, and uniform white finish | Available in a wide range of colors and shades |

| Cost | Generally higher due to white cement | Varies depending on pigment type and concentration |

| Uses | Architectural facades, decorative elements | Decorative floors, pavements, custom designs |

| Durability | High and resistant to weathering | Durability depends on pigment quality and mixing |

| Maintenance | Requires regular cleaning to maintain whiteness | Color stability needs proper sealing and care |

Key Differences Between White Concrete and Colored Concrete

White concrete is made using white cement and light-colored aggregates, resulting in a bright, clean appearance ideal for architectural and decorative applications. Colored concrete incorporates pigments into the mix to achieve a wide range of hues, offering greater versatility for design customization and creative finishes. The key differences lie in their composition, color uniformity, and cost, with white concrete providing a more consistent base color and colored concrete allowing for broader color options but potential variations.

Composition and Materials Used in White vs Colored Concrete

White concrete is primarily composed of white Portland cement, white aggregates such as quartz or limestone, and minimal iron content to achieve its bright appearance, whereas colored concrete incorporates regular gray Portland cement mixed with various pigments including iron oxides, chromium, and cobalt compounds to create a wide spectrum of hues. The white cement's low content of iron and manganese reduces discoloration, making it ideal for architectural applications requiring brightness, while colored concrete relies on synthetic or natural pigments blended into the mix to maintain color consistency throughout the material. Both types use similar base aggregates and admixtures, but the key difference lies in the cement's purity and the pigment additives that determine the final concrete color and aesthetic performance.

Visual Appeal: Aesthetic Impact of White and Colored Concrete

White concrete offers a sleek, modern aesthetic with a bright, clean surface that enhances natural lighting and creates a sense of spaciousness. Colored concrete provides versatile design options through pigmentation, allowing for customized hues that complement architectural styles and landscape designs. Both options maintain durability, but colored concrete can resist surface blemishes and fading better, preserving its visual appeal over time.

Durability and Performance Comparison

White concrete demonstrates superior durability due to its lower heat absorption and reduced thermal cracking, making it ideal for hot climates and reflective surfaces. Colored concrete, while offering aesthetic versatility, may experience slight reductions in strength and increased susceptibility to UV degradation depending on the pigments used. Performance differences largely depend on pigment quality and mix design, with white concrete often preferred for high-performance applications requiring longevity and structural integrity.

Applications: Where to Use White vs Colored Concrete

White concrete is ideal for architectural projects requiring a bright, clean aesthetic such as modern facades, decorative pavements, and interior floors where color uniformity enhances design elements. Colored concrete is preferred for landscaping, driveways, and patios where vibrant hues contribute to visual appeal and help define outdoor spaces. Both types offer durability and versatility, but choosing white or colored concrete depends on the desired style, environmental context, and functional requirements of the construction project.

Cost Considerations: White vs Colored Concrete

White concrete generally incurs higher costs compared to colored concrete due to the use of white cement and lighter aggregates, which are more expensive than traditional gray cement and pigments. Colored concrete, while offering a wide range of aesthetic options with integral pigments or stains, tends to be more cost-effective because it typically relies on standard gray cement combined with color additives. Project budgets must account for these material cost differences, as well as potential variations in labor and finishing techniques associated with each type of concrete.

Installation and Workability Differences

White concrete typically requires more precise mixing and careful water-to-cement ratios to maintain its bright appearance, leading to stricter quality control during installation. Colored concrete incorporates pigments that can affect setting times and workability, often necessitating adjustments in admixtures to achieve uniform color and consistent finish. Differences in drying rates and surface texture between white and colored concrete influence finishing techniques and curing processes on-site.

Maintenance and Lifespan: White Concrete vs Colored Concrete

White concrete typically requires less frequent maintenance than colored concrete because its light hue hides surface stains and fading more effectively. Colored concrete often needs periodic sealing and color touch-ups to maintain its vibrancy, which can increase overall upkeep costs. Both types offer long lifespans, but white concrete generally demonstrates better durability in UV exposure and weathering conditions.

Environmental Impact of White and Colored Concrete

White concrete demonstrates a higher albedo effect, reflecting more sunlight and reducing urban heat island intensity compared to colored concrete, which tends to absorb more solar radiation leading to increased surface temperatures. The production of colored concrete often requires additional pigments and additives, resulting in a slightly higher carbon footprint due to increased raw material processing and transportation. Lifecycle assessments indicate white concrete contributes to lower overall environmental impact by enhancing energy efficiency in urban environments through its reflective properties.

Choosing Between White and Colored Concrete for Your Project

White concrete offers a clean, bright foundation ideal for modern and minimalist designs, enhancing natural light reflection and providing a neutral base for architectural elements. Colored concrete allows for greater customization with a variety of pigments, enabling designers to match specific aesthetic requirements and create visually striking surfaces that complement landscaping or branding. Consider factors such as project location, desired ambiance, maintenance needs, and budget when deciding between white and colored concrete to achieve optimal durability and appearance.

White Concrete vs Colored Concrete Infographic

materialdif.com

materialdif.com