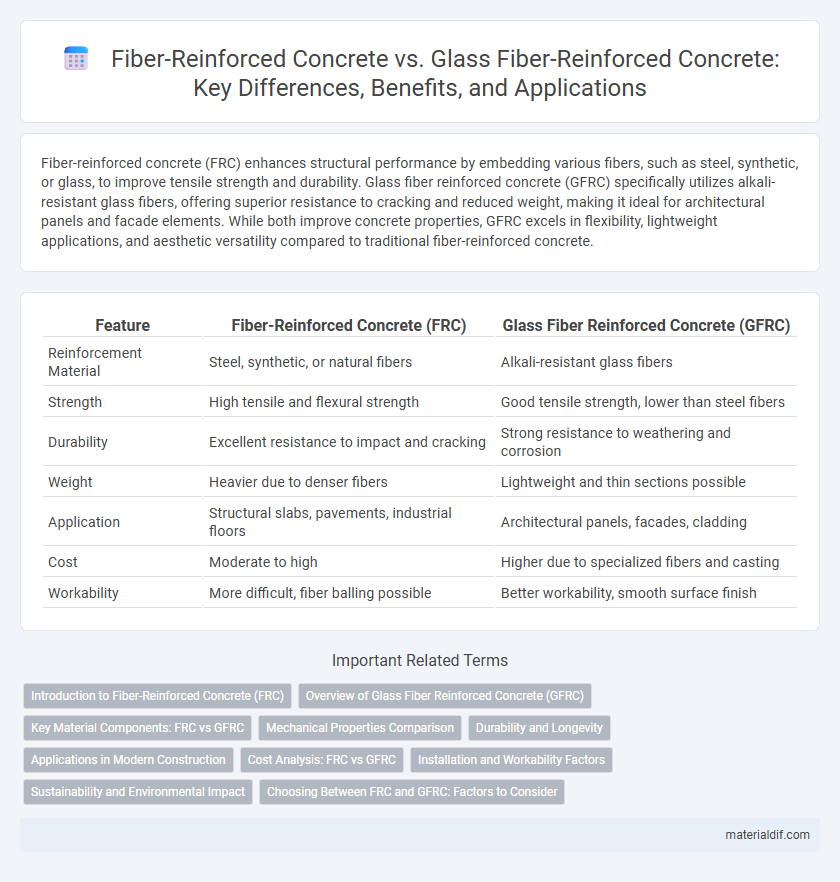

Fiber-reinforced concrete (FRC) enhances structural performance by embedding various fibers, such as steel, synthetic, or glass, to improve tensile strength and durability. Glass fiber reinforced concrete (GFRC) specifically utilizes alkali-resistant glass fibers, offering superior resistance to cracking and reduced weight, making it ideal for architectural panels and facade elements. While both improve concrete properties, GFRC excels in flexibility, lightweight applications, and aesthetic versatility compared to traditional fiber-reinforced concrete.

Table of Comparison

| Feature | Fiber-Reinforced Concrete (FRC) | Glass Fiber Reinforced Concrete (GFRC) |

|---|---|---|

| Reinforcement Material | Steel, synthetic, or natural fibers | Alkali-resistant glass fibers |

| Strength | High tensile and flexural strength | Good tensile strength, lower than steel fibers |

| Durability | Excellent resistance to impact and cracking | Strong resistance to weathering and corrosion |

| Weight | Heavier due to denser fibers | Lightweight and thin sections possible |

| Application | Structural slabs, pavements, industrial floors | Architectural panels, facades, cladding |

| Cost | Moderate to high | Higher due to specialized fibers and casting |

| Workability | More difficult, fiber balling possible | Better workability, smooth surface finish |

Introduction to Fiber-Reinforced Concrete (FRC)

Fiber-reinforced concrete (FRC) enhances structural performance by integrating various fibers, such as steel, synthetic, or glass, to improve tensile strength, durability, and crack resistance. Glass fiber reinforced concrete (GFRC) specifically utilizes alkali-resistant glass fibers, offering superior corrosion resistance and lightweight properties, making it ideal for architectural panels and thin-walled structures. Understanding the distinct fiber types and their mechanical advantages is essential in selecting the appropriate FRC for targeted construction applications.

Overview of Glass Fiber Reinforced Concrete (GFRC)

Glass Fiber Reinforced Concrete (GFRC) is a composite material that combines cement, fine aggregates, water, and alkali-resistant glass fibers, enhancing tensile strength and reducing weight compared to traditional concrete. The glass fibers improve durability, impact resistance, and flexibility, making GFRC ideal for architectural panels, cladding, and decorative elements. Its superior resistance to cracking and corrosion distinguishes GFRC from other fiber-reinforced concretes, providing long-lasting performance in diverse environmental conditions.

Key Material Components: FRC vs GFRC

Fiber-reinforced concrete (FRC) primarily utilizes steel, synthetic, or natural fibers to enhance tensile strength and ductility, improving crack resistance and overall durability. Glass fiber reinforced concrete (GFRC) incorporates alkali-resistant glass fibers specifically designed to prevent corrosion and provide lightweight, high-strength properties with increased flexibility in architectural applications. The key difference lies in fiber type and performance characteristics, where GFRC offers superior resistance to environmental degradation compared to traditional FRC materials.

Mechanical Properties Comparison

Fiber-reinforced concrete (FRC) exhibits enhanced tensile strength and toughness due to the inclusion of steel or synthetic fibers, improving crack resistance and durability under dynamic loading. Glass fiber reinforced concrete (GFRC) offers superior flexural strength and excellent resistance to shrinkage and thermal expansion, making it ideal for thin, lightweight architectural elements. Compared to traditional FRC, GFRC provides better corrosion resistance and increased impact resistance, though it generally has lower compressive strength.

Durability and Longevity

Fiber-reinforced concrete (FRC) exhibits enhanced durability through improved crack resistance and impact strength, extending structural lifespan under harsh conditions. Glass fiber reinforced concrete (GFRC) offers superior corrosion resistance and reduced permeability, making it ideal for environments prone to moisture and chemical exposure. Both materials significantly improve longevity compared to traditional concrete, with GFRC providing additional resilience against environmental degradation.

Applications in Modern Construction

Fiber-reinforced concrete (FRC) is widely used in modern construction for structural elements like slabs, pavements, and tunnels due to its enhanced tensile strength and crack resistance. Glass fiber reinforced concrete (GFRC) is preferred for architectural applications such as facades, decorative panels, and lightweight cladding because of its high durability, aesthetic flexibility, and resistance to corrosion. Both materials contribute to sustainable construction practices by reducing material thickness and extending the lifespan of concrete structures.

Cost Analysis: FRC vs GFRC

Fiber-reinforced concrete (FRC) typically demonstrates lower initial material costs compared to glass fiber reinforced concrete (GFRC) due to the affordability of steel or synthetic fibers versus glass fibers. However, GFRC offers enhanced durability and corrosion resistance that can reduce long-term maintenance and repair expenses, potentially offsetting higher upfront costs. Cost analysis must account for project scale, expected lifespan, and performance requirements to determine the most economical choice between FRC and GFRC.

Installation and Workability Factors

Fiber-reinforced concrete offers improved workability due to the uniform distribution of synthetic fibers, which enhances mixing and reduces segregation during installation. In contrast, glass fiber reinforced concrete requires careful handling as glass fibers can clump, affecting the consistency and ease of placement. Both types demand adjustments in mixing techniques, but glass fiber reinforced concrete often necessitates slower mixing speeds to prevent fiber damage and ensure proper dispersion.

Sustainability and Environmental Impact

Fiber-reinforced concrete (FRC) enhances structural durability and reduces maintenance frequency, leading to lower lifecycle environmental impact compared to conventional concrete. Glass fiber reinforced concrete (GFRC) incorporates alkali-resistant glass fibers, offering superior corrosion resistance and longer service life, which minimizes resource consumption and waste generation. GFRC's lightweight composition also reduces transportation emissions and energy use during installation, contributing to improved overall sustainability in construction projects.

Choosing Between FRC and GFRC: Factors to Consider

Fiber-reinforced concrete (FRC) offers enhanced tensile strength and crack resistance through synthetic or steel fibers, making it ideal for structural applications requiring durability and load-bearing capacity. Glass fiber reinforced concrete (GFRC) incorporates alkali-resistant glass fibers, providing superior tensile strength, flexibility, and reduced weight, often favored for architectural panels and decorative elements. Choosing between FRC and GFRC depends on factors such as exposure environment, aesthetic requirements, structural load demands, and cost-effectiveness for the specific construction project.

Fiber-reinforced concrete vs glass fiber reinforced concrete Infographic

materialdif.com

materialdif.com