Rapid-setting concrete achieves high strength quickly, making it ideal for emergency repairs and projects with tight timelines. Slow-curing concrete develops strength gradually, enhancing durability and reducing the risk of cracking over time. Choosing between rapid-setting and slow-curing concrete depends on project requirements for speed, strength, and long-term performance.

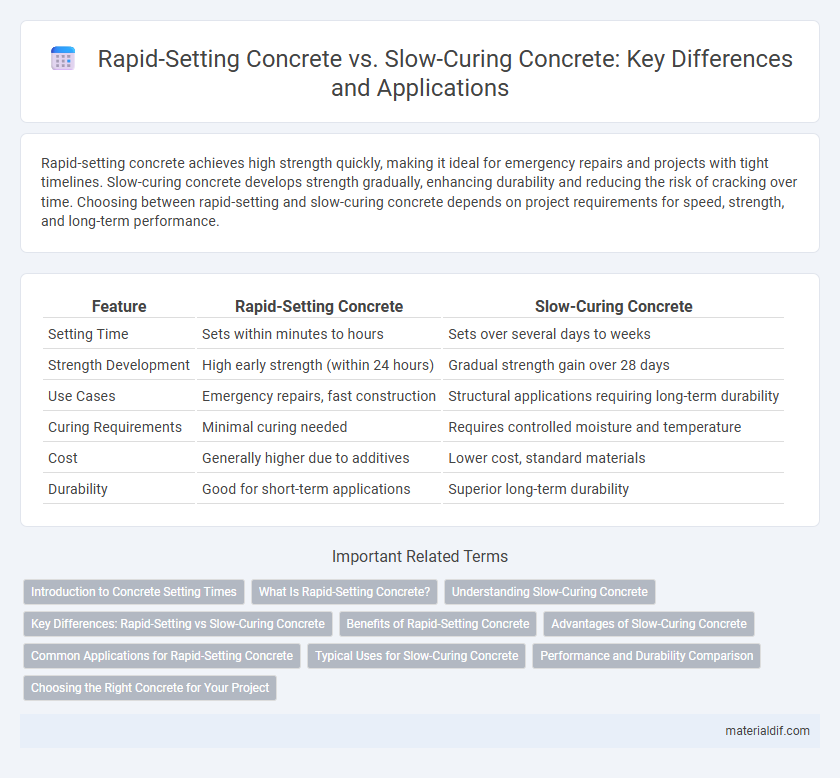

Table of Comparison

| Feature | Rapid-Setting Concrete | Slow-Curing Concrete |

|---|---|---|

| Setting Time | Sets within minutes to hours | Sets over several days to weeks |

| Strength Development | High early strength (within 24 hours) | Gradual strength gain over 28 days |

| Use Cases | Emergency repairs, fast construction | Structural applications requiring long-term durability |

| Curing Requirements | Minimal curing needed | Requires controlled moisture and temperature |

| Cost | Generally higher due to additives | Lower cost, standard materials |

| Durability | Good for short-term applications | Superior long-term durability |

Introduction to Concrete Setting Times

Rapid-setting concrete achieves initial hardness within 30 minutes to a few hours, making it ideal for emergency repairs and projects requiring fast turnaround. Slow-curing concrete, on the other hand, gains strength over days or weeks, providing enhanced durability and reduced shrinkage. Understanding the setting times is crucial for selecting the appropriate mix to meet specific structural and environmental demands.

What Is Rapid-Setting Concrete?

Rapid-setting concrete is a specialized type of concrete designed to harden and gain strength much faster than traditional slow-curing concrete, typically within minutes to hours rather than days. It contains chemical accelerators such as calcium chloride or rapid-hardening cement that promote quicker hydration and early strength development, making it ideal for urgent repairs and time-sensitive construction projects. Rapid-setting concrete is commonly used in road patching, emergency repairs, and precast concrete production where minimizing downtime and fast load-bearing capacity are critical.

Understanding Slow-Curing Concrete

Slow-curing concrete develops strength gradually over an extended period, typically taking 28 days or more to reach its full compressive capacity. This type of concrete offers enhanced durability and superior resistance to environmental factors due to its prolonged hydration process. The slower curing process minimizes shrinkage cracks and improves long-term performance in structural applications.

Key Differences: Rapid-Setting vs Slow-Curing Concrete

Rapid-setting concrete achieves initial set within minutes to hours, enabling faster construction progress and early load-bearing capacity, while slow-curing concrete requires days to weeks to develop strength, ensuring enhanced durability and reduced cracking risk. Rapid-setting variants are ideal for emergency repairs and projects with tight timelines, whereas slow-curing types offer superior long-term performance in structural applications. Differences in hydration rate, ambient temperature sensitivity, and curing methods significantly impact the mechanical properties and lifespan of each concrete type.

Benefits of Rapid-Setting Concrete

Rapid-setting concrete accelerates construction timelines by achieving initial set typically within 30 minutes to 2 hours, enabling faster project turnaround and reducing labor costs. Its high early strength development supports quick load-bearing capacity, making it ideal for emergency repairs, road maintenance, and industrial flooring. This type of concrete also minimizes downtime in infrastructure projects, improving overall efficiency and cost-effectiveness compared to slow-curing alternatives.

Advantages of Slow-Curing Concrete

Slow-curing concrete enhances long-term durability by allowing proper hydration, resulting in higher compressive strength and reduced permeability. Its gradual setting process minimizes cracking and shrinkage, improving structural integrity in demanding environments. This type of concrete is optimal for projects requiring maximum resilience and longevity, such as bridges and high-rise buildings.

Common Applications for Rapid-Setting Concrete

Rapid-setting concrete is commonly used in urgent repair works such as highway potholes, airport runways, and emergency structural fixes due to its accelerated strength development within hours. It is ideal for projects requiring quick turnaround times, including utility repairs and winter construction where fast curing is essential to prevent weather-related delays. This type of concrete enables minimal downtime in infrastructure maintenance and fast reopening of critical facilities.

Typical Uses for Slow-Curing Concrete

Slow-curing concrete is typically used in large-scale infrastructure projects such as bridges, dams, and highways where long-term strength and durability are critical. This type of concrete allows for gradual hydration, reducing the risk of cracking and improving resistance to environmental stresses over time. It is also favored in architectural applications where superior surface finish and dimensional stability are essential.

Performance and Durability Comparison

Rapid-setting concrete achieves high early strength within hours, making it ideal for emergency repairs and time-sensitive projects, while slow-curing concrete develops strength gradually, enhancing long-term durability and resistance to cracking. The accelerated hydration process in rapid-setting concrete can lead to increased porosity and reduced ultimate strength, whereas slow-curing concrete benefits from prolonged moisture retention that improves microstructural density and reduces permeability. Performance metrics indicate rapid-setting concrete excels in early load-bearing capacity but may exhibit lower lifespan and susceptibility to shrinkage-related issues compared to the superior durability and mechanical properties of slow-curing concrete under sustained environmental exposure.

Choosing the Right Concrete for Your Project

Rapid-setting concrete offers accelerated strength gain within hours, ideal for urgent repairs and cold weather applications, while slow-curing concrete ensures enhanced durability and reduced shrinkage through extended hydration. Selecting concrete depends on project timelines, environmental conditions, and load requirements, with rapid-setting preferred for fast turnaround and slow-curing favored for structural longevity. Understanding curing time and performance characteristics guarantees optimal concrete performance and lifecycle cost-efficiency.

Rapid-setting concrete vs slow-curing concrete Infographic

materialdif.com

materialdif.com