Fly ash concrete offers improved workability, reduced heat of hydration, and enhanced long-term strength compared to traditional mixes. Slag cement concrete provides superior durability, increased resistance to chemical attack, and better sulfate resistance, making it ideal for harsh environments. Both materials contribute to sustainability by recycling industrial byproducts while improving concrete performance.

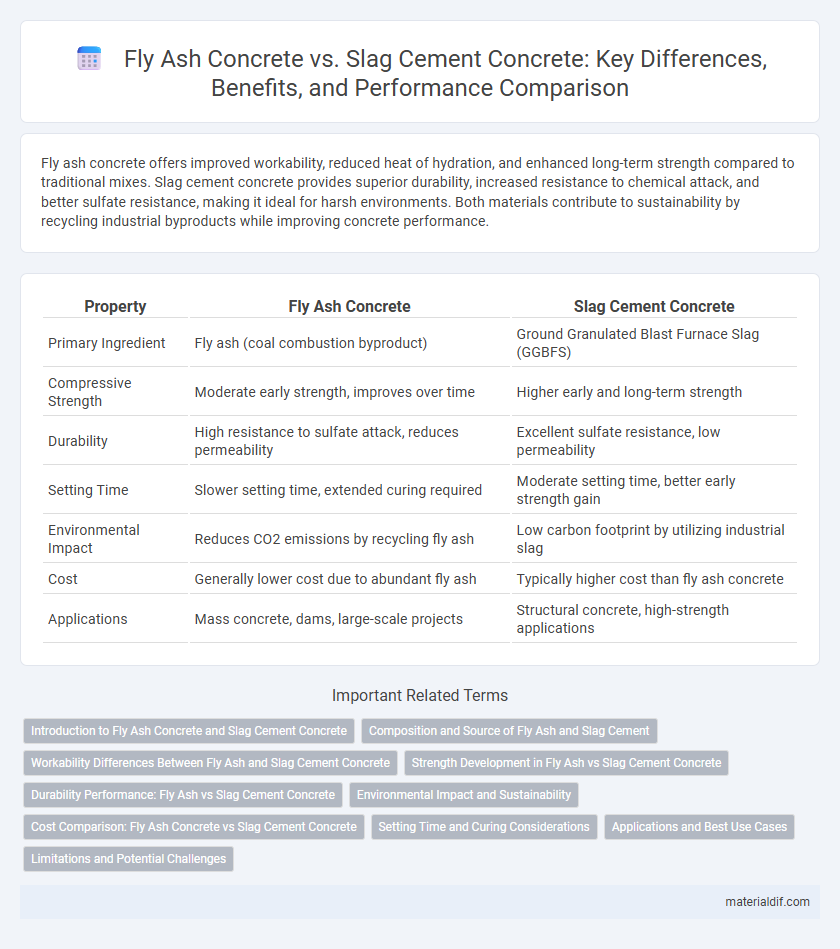

Table of Comparison

| Property | Fly Ash Concrete | Slag Cement Concrete |

|---|---|---|

| Primary Ingredient | Fly ash (coal combustion byproduct) | Ground Granulated Blast Furnace Slag (GGBFS) |

| Compressive Strength | Moderate early strength, improves over time | Higher early and long-term strength |

| Durability | High resistance to sulfate attack, reduces permeability | Excellent sulfate resistance, low permeability |

| Setting Time | Slower setting time, extended curing required | Moderate setting time, better early strength gain |

| Environmental Impact | Reduces CO2 emissions by recycling fly ash | Low carbon footprint by utilizing industrial slag |

| Cost | Generally lower cost due to abundant fly ash | Typically higher cost than fly ash concrete |

| Applications | Mass concrete, dams, large-scale projects | Structural concrete, high-strength applications |

Introduction to Fly Ash Concrete and Slag Cement Concrete

Fly ash concrete incorporates a byproduct from coal combustion, enhancing workability and durability while reducing permeability and heat of hydration. Slag cement concrete uses ground granulated blast-furnace slag (GGBFS), improving resistance to chemical attacks and increasing long-term strength. Both materials serve as supplementary cementitious materials, promoting sustainability by reducing Portland cement usage and lowering carbon emissions in construction.

Composition and Source of Fly Ash and Slag Cement

Fly ash concrete incorporates fly ash, a byproduct of coal combustion in power plants, predominantly composed of silica, alumina, and iron oxides, enhancing concrete strength and durability. Slag cement concrete uses ground granulated blast-furnace slag (GGBFS), derived from the molten iron slag of steel manufacturing, rich in calcium, silica, and alumina, which improves concrete's resistance to chemical attack and reduces permeability. Both materials serve as supplementary cementitious substances, replacing a portion of Portland cement to promote sustainability and improve concrete performance.

Workability Differences Between Fly Ash and Slag Cement Concrete

Fly ash concrete typically exhibits improved workability compared to slag cement concrete due to the spherical shape of fly ash particles, which act as lubricants in the mix, reducing water demand and enhancing fluidity. Slag cement concrete, while also enhancing workability, often requires slightly more water or admixtures to achieve comparable flow characteristics because of the angular and irregular shape of slag particles. These differences affect finishing processes and pumpability, with fly ash concrete generally offering smoother placement and reduced bleeding.

Strength Development in Fly Ash vs Slag Cement Concrete

Fly ash concrete typically exhibits slower early strength development compared to slag cement concrete, gaining significant strength after 28 days due to the pozzolanic reaction. Slag cement concrete achieves higher early strength as the latent hydraulic properties of slag contribute to quicker cementitious reactions. Long-term strength of both fly ash and slag cement concrete often surpasses that of ordinary Portland cement concrete, with slag cement concrete generally demonstrating superior strength performance at earlier ages.

Durability Performance: Fly Ash vs Slag Cement Concrete

Fly ash concrete exhibits excellent durability performance due to its ability to reduce permeability and enhance resistance to sulfate attack and alkali-silica reaction. Slag cement concrete offers superior durability in aggressive environments by improving resistance to chloride ingress, freeze-thaw cycles, and corrosion of reinforcement. Both materials enhance concrete's lifespan, but slag cement generally provides greater protection against chemical and physical degradation.

Environmental Impact and Sustainability

Fly ash concrete significantly reduces carbon dioxide emissions by utilizing industrial byproducts, lowering the demand for traditional Portland cement which is energy-intensive to produce. Slag cement concrete also promotes sustainability through recycling granulated blast furnace slag, decreasing landfill waste and further reducing greenhouse gas emissions. Both materials enhance durability and lifespan of concrete structures, minimizing resource consumption and environmental degradation over time.

Cost Comparison: Fly Ash Concrete vs Slag Cement Concrete

Fly ash concrete generally offers a lower cost compared to slag cement concrete due to the abundant availability and lower processing expenses of fly ash as a byproduct of coal combustion. Slag cement, derived from ground granulated blast-furnace slag, tends to have higher material costs influenced by steel production demand and transportation factors. Overall, fly ash concrete presents a more economical option for large-scale construction projects when considering material price and supply consistency.

Setting Time and Curing Considerations

Fly ash concrete generally exhibits a slower setting time compared to slag cement concrete due to the pozzolanic reaction kinetics of fly ash, which require extended curing to achieve optimal strength. Slag cement concrete typically offers faster initial set and earlier strength gain, making it suitable for projects with tight schedules. Proper curing is essential for both types to enhance durability and minimize shrinkage cracking, with moist curing extending up to 7 days for slag cement and 14 days or more recommended for fly ash concrete.

Applications and Best Use Cases

Fly ash concrete is ideal for large-scale infrastructure projects like dams, bridges, and high-rise buildings due to its enhanced workability, reduced heat of hydration, and improved durability in sulfate-rich environments. Slag cement concrete excels in marine structures, sewage treatment plants, and foundations exposed to aggressive chemicals because of its superior resistance to chloride and sulfate attack. Both materials optimize sustainability, but fly ash concrete is preferred for reducing heat and improving pumpability, while slag cement concrete is chosen for aggressive chemical exposure and high early strength development.

Limitations and Potential Challenges

Fly ash concrete may experience slower early strength development and increased susceptibility to carbonation, affecting durability in certain environments. Slag cement concrete often faces challenges related to longer setting times and potential variability in slag chemistry, which can impact consistency and performance. Both materials require careful quality control and mix design adjustments to address these limitations and optimize structural integrity.

Fly Ash Concrete vs Slag Cement Concrete Infographic

materialdif.com

materialdif.com