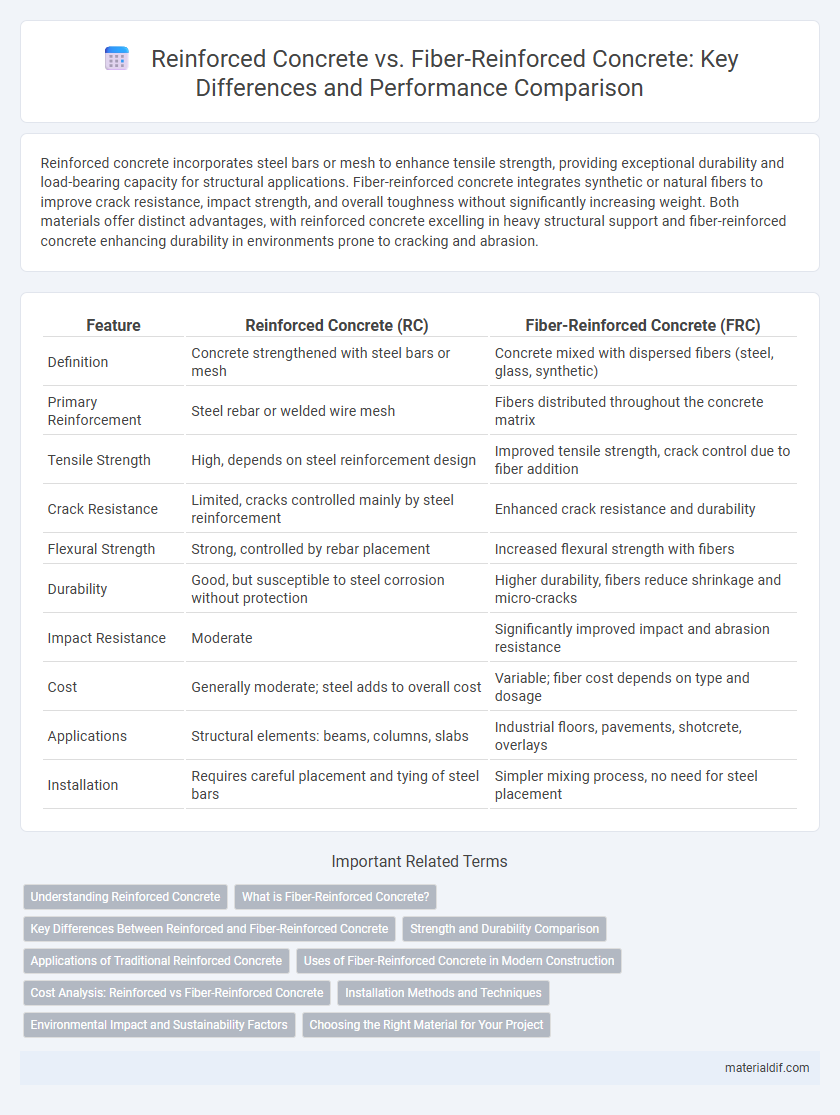

Reinforced concrete incorporates steel bars or mesh to enhance tensile strength, providing exceptional durability and load-bearing capacity for structural applications. Fiber-reinforced concrete integrates synthetic or natural fibers to improve crack resistance, impact strength, and overall toughness without significantly increasing weight. Both materials offer distinct advantages, with reinforced concrete excelling in heavy structural support and fiber-reinforced concrete enhancing durability in environments prone to cracking and abrasion.

Table of Comparison

| Feature | Reinforced Concrete (RC) | Fiber-Reinforced Concrete (FRC) |

|---|---|---|

| Definition | Concrete strengthened with steel bars or mesh | Concrete mixed with dispersed fibers (steel, glass, synthetic) |

| Primary Reinforcement | Steel rebar or welded wire mesh | Fibers distributed throughout the concrete matrix |

| Tensile Strength | High, depends on steel reinforcement design | Improved tensile strength, crack control due to fiber addition |

| Crack Resistance | Limited, cracks controlled mainly by steel reinforcement | Enhanced crack resistance and durability |

| Flexural Strength | Strong, controlled by rebar placement | Increased flexural strength with fibers |

| Durability | Good, but susceptible to steel corrosion without protection | Higher durability, fibers reduce shrinkage and micro-cracks |

| Impact Resistance | Moderate | Significantly improved impact and abrasion resistance |

| Cost | Generally moderate; steel adds to overall cost | Variable; fiber cost depends on type and dosage |

| Applications | Structural elements: beams, columns, slabs | Industrial floors, pavements, shotcrete, overlays |

| Installation | Requires careful placement and tying of steel bars | Simpler mixing process, no need for steel placement |

Understanding Reinforced Concrete

Reinforced concrete combines concrete's compressive strength with steel reinforcement bars to improve tensile strength, making it essential in construction for structural integrity and durability. Steel reinforcement resists tensile forces, crack propagation, and enhances load-bearing capacity, which typical concrete alone cannot withstand effectively. This composite material is extensively used in beams, columns, slabs, and foundations where resistance to bending and shear stresses is critical.

What is Fiber-Reinforced Concrete?

Fiber-reinforced concrete (FRC) is a composite material that integrates fibrous materials such as steel, glass, synthetic, or natural fibers into the concrete matrix to improve its structural performance. These fibers enhance tensile strength, reduce cracking, and increase durability compared to traditional reinforced concrete, which relies on steel bars or mesh for reinforcement. FRC is widely used in applications requiring higher impact resistance, reduced shrinkage, and improved flexural strength.

Key Differences Between Reinforced and Fiber-Reinforced Concrete

Reinforced concrete incorporates steel bars or mesh to enhance tensile strength, while fiber-reinforced concrete uses synthetic or steel fibers dispersed throughout the mix to improve toughness and crack resistance. Reinforced concrete excels in handling structural loads, whereas fiber-reinforced concrete provides better impact resistance and controls shrinkage cracks. The choice between them depends on project requirements for load-bearing capacity, durability, and resistance to cracking.

Strength and Durability Comparison

Reinforced concrete utilizes steel bars to enhance tensile strength, providing robust load-bearing capacity ideal for structural applications. Fiber-reinforced concrete incorporates synthetic or metallic fibers, improving crack resistance and toughness while maintaining comparable compressive strength. Durability assessments show fiber-reinforced concrete offers superior resistance to impact, shrinkage, and corrosion-related deterioration compared to traditional reinforced concrete.

Applications of Traditional Reinforced Concrete

Traditional reinforced concrete is widely used in the construction of bridges, high-rise buildings, and foundations due to its high compressive strength and structural durability. Steel reinforcement bars embedded within the concrete provide tensile strength, making it ideal for load-bearing applications and infrastructure projects requiring long-term stability. Its versatility in shaping and cost-effectiveness have cemented its role in commercial, residential, and industrial construction.

Uses of Fiber-Reinforced Concrete in Modern Construction

Fiber-reinforced concrete (FRC) enhances structural durability and crack resistance, making it ideal for pavements, industrial floors, and tunnel linings in modern construction. Its improved tensile strength and impact resistance allow for reduced slab thickness and lower maintenance costs compared to traditional reinforced concrete. The adaptability of FRC in pre-stressed elements, shotcrete applications, and earthquake-resistant structures drives its growing use in innovative engineering projects.

Cost Analysis: Reinforced vs Fiber-Reinforced Concrete

Reinforced concrete typically involves steel bars or mesh, which can lead to higher material and labor costs due to corrosion protection and installation complexity. Fiber-reinforced concrete incorporates synthetic or steel fibers distributed throughout the mixture, reducing labor expenses and enhancing durability, often resulting in lower maintenance costs over time. Cost analysis must consider initial investment, lifecycle expenses, and specific application requirements to determine the most economical choice.

Installation Methods and Techniques

Reinforced concrete installation involves placing steel rebar within forms before pouring concrete, requiring precise positioning and secure tying to ensure structural integrity. Fiber-reinforced concrete eliminates the need for traditional rebar by mixing synthetic or steel fibers directly into the concrete, allowing for faster application and reduced labor during placement. Techniques for fiber-reinforced concrete focus on uniform fiber dispersion and controlled vibration to avoid fiber balling, enhancing durability and crack resistance in construction projects.

Environmental Impact and Sustainability Factors

Reinforced concrete, traditionally made with steel bars, has a significant carbon footprint due to steel production and contributes to higher embodied energy in construction. Fiber-reinforced concrete incorporates synthetic or natural fibers that reduce steel usage, lowering overall material consumption and improving durability, which extends structure lifespan and reduces maintenance frequency. The reduced resource demand and potential for recycling fibers enhance the sustainability profile of fiber-reinforced concrete compared to conventional reinforced concrete.

Choosing the Right Material for Your Project

Reinforced concrete employs steel bars to enhance tensile strength, making it ideal for structural elements subjected to heavy loads. Fiber-reinforced concrete integrates synthetic or steel fibers to improve crack resistance and durability, suitable for slabs, pavements, and repair works. Selecting between the two depends on project requirements, balancing factors like load capacity, flexibility, cost, and maintenance needs.

Reinforced Concrete vs Fiber-Reinforced Concrete Infographic

materialdif.com

materialdif.com