Ready-mix concrete offers precise batching and consistent quality by being prepared in a controlled plant environment, reducing material waste and labor costs on-site. Site-mixed concrete provides flexibility for small projects or urgent repairs, allowing immediate adjustments to mix design but often results in variable quality and longer preparation time. Choosing between ready-mix and site-mixed concrete depends on project scale, quality requirements, and logistical considerations.

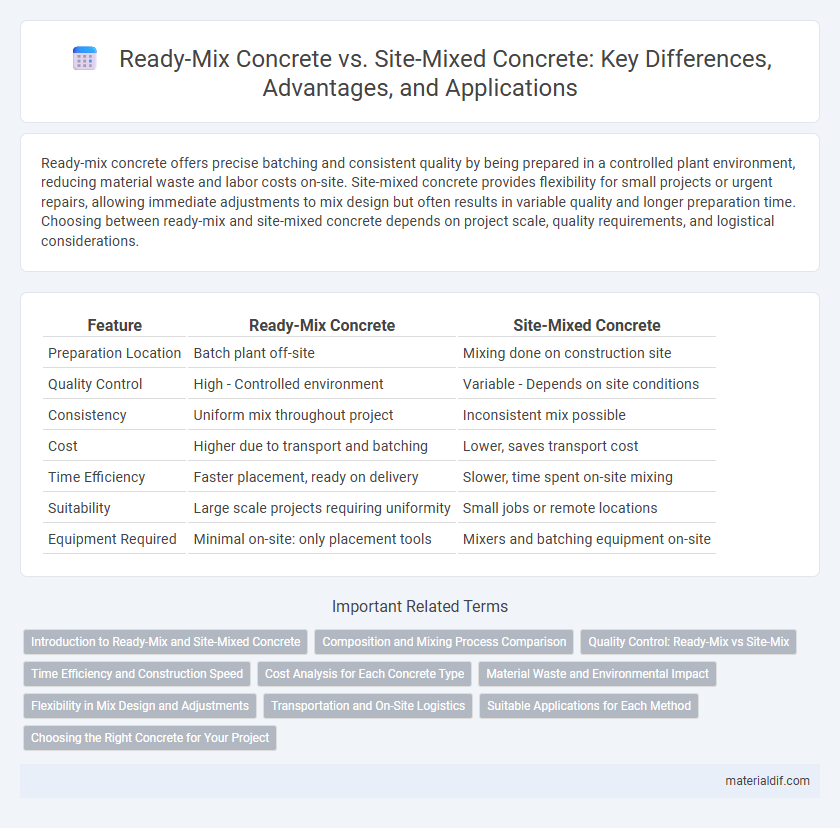

Table of Comparison

| Feature | Ready-Mix Concrete | Site-Mixed Concrete |

|---|---|---|

| Preparation Location | Batch plant off-site | Mixing done on construction site |

| Quality Control | High - Controlled environment | Variable - Depends on site conditions |

| Consistency | Uniform mix throughout project | Inconsistent mix possible |

| Cost | Higher due to transport and batching | Lower, saves transport cost |

| Time Efficiency | Faster placement, ready on delivery | Slower, time spent on-site mixing |

| Suitability | Large scale projects requiring uniformity | Small jobs or remote locations |

| Equipment Required | Minimal on-site: only placement tools | Mixers and batching equipment on-site |

Introduction to Ready-Mix and Site-Mixed Concrete

Ready-mix concrete is a pre-mixed batch of concrete manufactured at a centralized plant, ensuring precise proportions of cement, aggregates, water, and admixtures for consistent quality and strength. Site-mixed concrete involves on-site blending of raw materials, offering flexibility but often resulting in variable consistency and potential quality issues due to manual mixing processes. The choice between ready-mix and site-mixed concrete depends on project scale, required quality control, and logistical considerations.

Composition and Mixing Process Comparison

Ready-mix concrete is manufactured in a controlled plant environment where precise proportions of cement, water, aggregates, and admixtures are mixed to ensure consistent quality and strength. Site-mixed concrete, however, involves on-site blending of ingredients using manual or machine mixers, which can lead to variations in composition and potential inconsistencies in the final product. The standardized mixing process of ready-mix concrete improves uniformity and reduces waste compared to the less controlled and labor-intensive site-mixed method.

Quality Control: Ready-Mix vs Site-Mix

Ready-mix concrete offers superior quality control through precise batching in controlled plant conditions, ensuring consistent strength and durability. Site-mixed concrete often suffers from variability due to manual measurements and environmental factors, leading to inconsistent performance. Advanced technology in ready-mix plants enables real-time monitoring and adjustments, minimizing human error and enhancing overall concrete quality.

Time Efficiency and Construction Speed

Ready-mix concrete significantly enhances time efficiency by arriving pre-mixed and ready to pour, eliminating on-site batching and reducing labor requirements. This pre-prepared material accelerates construction speed, enabling continuous workflow and minimizing delays caused by mixing errors or inconsistent quality. In contrast, site-mixed concrete requires longer preparation times and involves more variability, which can slow down project timelines and increase the risk of rework.

Cost Analysis for Each Concrete Type

Ready-mix concrete typically incurs higher initial costs due to factory batching, transportation, and delivery fees, but reduces on-site labor and equipment expenses, resulting in overall cost efficiency for large-scale projects. Site-mixed concrete lowers upfront material transportation costs by batching directly on-site, but increases labor hours, equipment rental, and waste disposal expenses, which can elevate total project costs. Careful assessment of project size, labor rates, and location logistics is essential to choosing the most cost-effective concrete option.

Material Waste and Environmental Impact

Ready-mix concrete significantly reduces material waste by precisely batching ingredients in controlled plants, minimizing excess and spillage compared to site-mixed concrete. This reduction in waste leads to lower environmental impact through decreased resource consumption and less onsite disposal. Additionally, ready-mix concrete production optimizes energy use and lowers carbon emissions, contributing to more sustainable construction practices.

Flexibility in Mix Design and Adjustments

Ready-mix concrete offers limited flexibility in mix design and adjustments due to its pre-batched nature, often requiring precise early planning to meet specific project requirements. Site-mixed concrete allows for on-the-spot modifications to the mix proportions, enabling real-time adaptation to changing environmental conditions or project needs. This flexibility makes site-mixed concrete particularly advantageous for projects demanding custom or variable concrete properties during construction.

Transportation and On-Site Logistics

Ready-mix concrete is delivered from the batching plant to the construction site using specialized mixer trucks that maintain the concrete's consistency and workability during transit, reducing onsite labor and minimizing waste. Site-mixed concrete requires transporting raw materials separately, causing increased logistics complexity, longer preparation times, and higher chances of quality variation due to on-site mixing conditions. Efficient transportation and precise scheduling for ready-mix concrete optimize construction timelines and ensure consistent material performance compared to the unpredictable nature of site-mixed concrete logistics.

Suitable Applications for Each Method

Ready-mix concrete is ideal for large-scale projects requiring consistent quality and rapid placement, such as commercial buildings, bridges, and infrastructure developments. Site-mixed concrete suits small-scale construction or remote locations where ready-mix delivery is impractical, allowing greater control over mix proportions on-site. Selecting between these methods depends on project size, timing, and specific structural requirements.

Choosing the Right Concrete for Your Project

Ready-mix concrete offers consistent quality, precise mix proportions, and faster application, making it ideal for large-scale projects requiring uniform strength and durability. Site-mixed concrete provides flexibility in mix adjustments on-site and may reduce transportation costs for smaller projects or remote locations. Selecting the right concrete depends on project size, timeline, quality requirements, and accessibility to ensure optimal performance and cost-efficiency.

Ready-Mix Concrete vs Site-Mixed Concrete Infographic

materialdif.com

materialdif.com