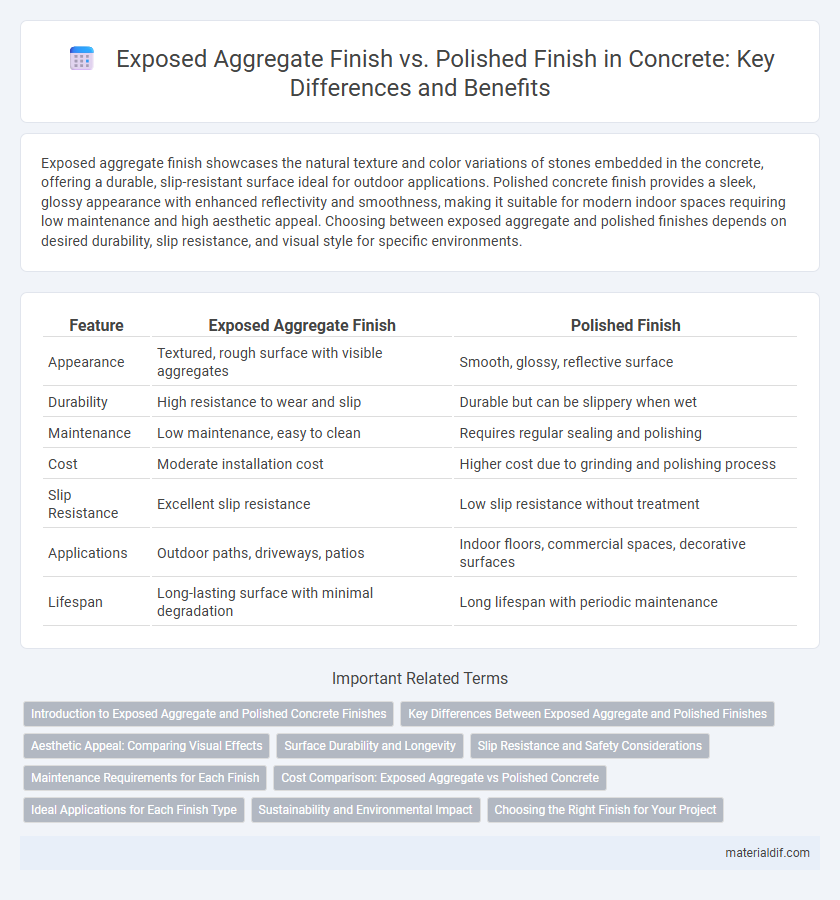

Exposed aggregate finish showcases the natural texture and color variations of stones embedded in the concrete, offering a durable, slip-resistant surface ideal for outdoor applications. Polished concrete finish provides a sleek, glossy appearance with enhanced reflectivity and smoothness, making it suitable for modern indoor spaces requiring low maintenance and high aesthetic appeal. Choosing between exposed aggregate and polished finishes depends on desired durability, slip resistance, and visual style for specific environments.

Table of Comparison

| Feature | Exposed Aggregate Finish | Polished Finish |

|---|---|---|

| Appearance | Textured, rough surface with visible aggregates | Smooth, glossy, reflective surface |

| Durability | High resistance to wear and slip | Durable but can be slippery when wet |

| Maintenance | Low maintenance, easy to clean | Requires regular sealing and polishing |

| Cost | Moderate installation cost | Higher cost due to grinding and polishing process |

| Slip Resistance | Excellent slip resistance | Low slip resistance without treatment |

| Applications | Outdoor paths, driveways, patios | Indoor floors, commercial spaces, decorative surfaces |

| Lifespan | Long-lasting surface with minimal degradation | Long lifespan with periodic maintenance |

Introduction to Exposed Aggregate and Polished Concrete Finishes

Exposed aggregate concrete showcases the natural textures and colors of stones embedded in the surface, offering a slip-resistant and visually striking finish ideal for driveways and walkways. Polished concrete involves mechanically grinding and sealing the surface to achieve a smooth, reflective, and low-maintenance finish commonly used in commercial and indoor spaces. Both finishes enhance durability and aesthetic appeal, with exposed aggregate emphasizing texture and natural variation while polished concrete highlights shine and uniformity.

Key Differences Between Exposed Aggregate and Polished Finishes

Exposed aggregate finish reveals the natural textures of stones and gravel, creating a rough, slip-resistant surface ideal for outdoor pathways and decorative features. Polished finish smooths the concrete surface to a glossy, reflective sheen by grinding and polishing, enhancing durability and stain resistance suited for indoor flooring. Key differences include texture, maintenance requirements, aesthetic appeal, and slip resistance, with exposed aggregate providing a coarse, natural look and polished concrete offering a sleek, modern appearance.

Aesthetic Appeal: Comparing Visual Effects

Exposed aggregate finish showcases a textured surface with embedded stones that create a natural, rugged appearance, enhancing outdoor spaces with tactile visual interest. Polished finish offers a sleek, glossy surface that reflects light, providing a modern and sophisticated look ideal for indoor environments. Choosing between exposed aggregate and polished finishes depends on the desired aesthetic effect, with exposed aggregate emphasizing organic texture and polished emphasizing smooth elegance.

Surface Durability and Longevity

Exposed aggregate finish offers superior surface durability due to its rough texture, which resists wear and slip effectively, making it ideal for outdoor applications. Polished concrete finish provides enhanced longevity through a dense, hardened surface achieved by mechanical polishing, which also minimizes dusting and surface damage. Both finishes extend concrete lifespan, but exposed aggregate is better for high-traction needs, while polished concrete excels in abrasion resistance and ease of maintenance.

Slip Resistance and Safety Considerations

Exposed aggregate concrete provides enhanced slip resistance due to its textured surface, making it ideal for outdoor walkways and pool decks where safety is critical. Polished concrete, while visually appealing with a smooth, reflective finish, tends to be more slippery, especially when wet, requiring additional treatments or coatings to improve traction. Considering safety, exposed aggregate finishes are preferable in environments prone to moisture and heavy foot traffic to minimize slip hazards.

Maintenance Requirements for Each Finish

Exposed aggregate finish requires periodic sealing to prevent surface staining and maintain its textured appearance, while occasional cleaning with a broom or mild detergent is sufficient to preserve its durability. Polished finish demands regular dust mopping and frequent wet cleaning with neutral pH cleaners to sustain its glossy surface and protect the integrity of the polished concrete. Neglecting maintenance in either finish can lead to surface wear or discoloration, reducing the lifespan and aesthetic appeal of the concrete.

Cost Comparison: Exposed Aggregate vs Polished Concrete

Exposed aggregate concrete generally costs less than polished concrete due to simpler surface treatment and lower labor intensity, with prices typically ranging from $6 to $12 per square foot compared to $8 to $15 per square foot for polished finishes. Polished concrete requires specialized equipment and multiple grinding and sealing steps, increasing material and labor expenses. Budget considerations often favor exposed aggregate for large projects seeking durability and aesthetics at reduced cost, while polished concrete suits high-end applications where surface smoothness and reflectivity justify the premium.

Ideal Applications for Each Finish Type

Exposed aggregate finish is ideal for outdoor applications such as driveways, patios, and walkways where slip resistance and a decorative textured surface are desired. Polished concrete finish is best suited for indoor environments like commercial floors, retail spaces, and residential interiors, providing a sleek, durable, and low-maintenance surface. Both finishes enhance concrete durability but serve different aesthetic and functional needs based on the exposure and use conditions.

Sustainability and Environmental Impact

Exposed aggregate finish enhances sustainability by using naturally sourced aggregates and reduces the need for chemical sealers, lowering environmental impact. Polished finish requires extensive grinding and frequent maintenance, leading to higher energy consumption and increased emissions over its lifecycle. Choosing exposed aggregate supports eco-friendly construction practices through durability and minimal resource use.

Choosing the Right Finish for Your Project

Exposed aggregate finish offers a textured, slip-resistant surface ideal for outdoor areas like driveways and walkways, enhancing durability and natural aesthetic appeal. Polished finish provides a smooth, glossy surface perfect for indoor spaces, delivering a modern look with easy maintenance and increased resistance to stains and wear. Selecting the right finish depends on project needs such as location, desired appearance, and functional requirements, balancing durability with visual impact.

Exposed aggregate finish vs polished finish Infographic

materialdif.com

materialdif.com