Reinforced concrete contains steel bars or mesh that enhance tensile strength, making it ideal for structural applications requiring durability and load-bearing capacity. Plain concrete lacks reinforcement and primarily withstands compressive forces, which limits its use to non-structural elements or surfaces. The integration of reinforcement significantly improves crack resistance and overall longevity in construction projects.

Table of Comparison

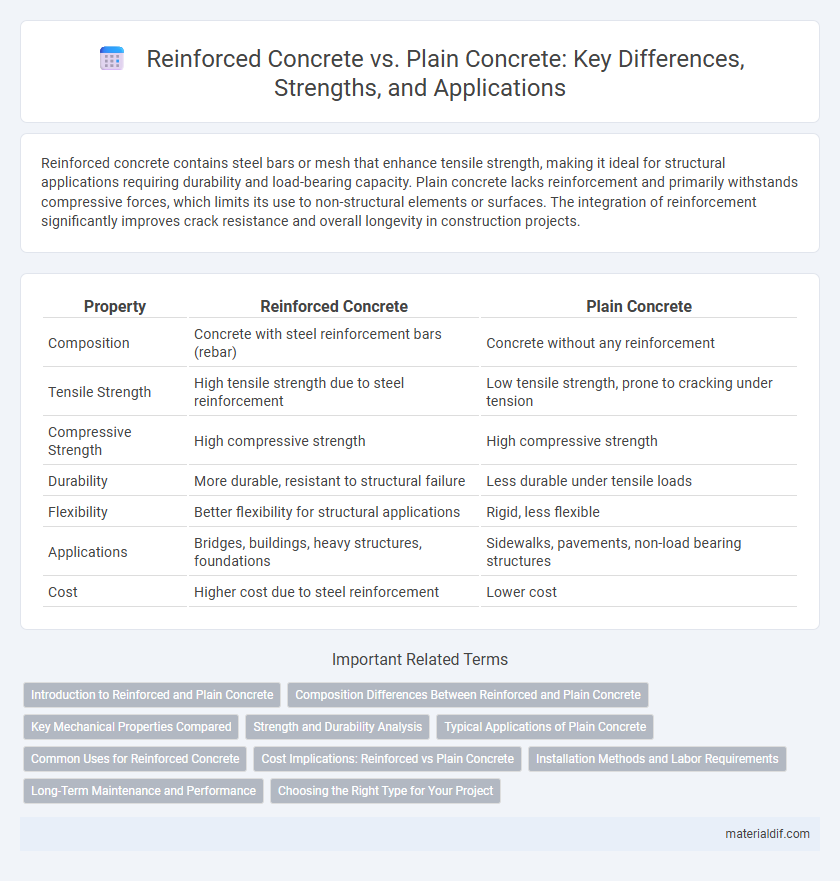

| Property | Reinforced Concrete | Plain Concrete |

|---|---|---|

| Composition | Concrete with steel reinforcement bars (rebar) | Concrete without any reinforcement |

| Tensile Strength | High tensile strength due to steel reinforcement | Low tensile strength, prone to cracking under tension |

| Compressive Strength | High compressive strength | High compressive strength |

| Durability | More durable, resistant to structural failure | Less durable under tensile loads |

| Flexibility | Better flexibility for structural applications | Rigid, less flexible |

| Applications | Bridges, buildings, heavy structures, foundations | Sidewalks, pavements, non-load bearing structures |

| Cost | Higher cost due to steel reinforcement | Lower cost |

Introduction to Reinforced and Plain Concrete

Reinforced concrete combines concrete's high compressive strength with steel reinforcement's tensile strength, enhancing durability and load-bearing capacity. Plain concrete relies solely on its compressive strength, making it suitable for non-structural elements with minimal tensile stress. Understanding the distinct properties and applications of reinforced and plain concrete is essential for optimal construction design.

Composition Differences Between Reinforced and Plain Concrete

Reinforced concrete integrates steel bars or mesh within the concrete matrix, enhancing tensile strength and crack resistance, whereas plain concrete consists solely of cement, sand, aggregate, and water, providing high compressive strength but low tensile capacity. The steel reinforcement in reinforced concrete compensates for concrete's inherent weakness in tension, resulting in a composite material optimized for structural applications requiring flexibility and load-bearing capability. In contrast, plain concrete's simple composition suits non-structural or low-stress uses where tensile forces are minimal.

Key Mechanical Properties Compared

Reinforced concrete exhibits higher tensile strength and improved ductility compared to plain concrete, which primarily excels in compressive strength but is brittle under tension. The embedded steel reinforcement in reinforced concrete enhances its load-bearing capacity, making it suitable for dynamic and tensile applications. Plain concrete, while cost-effective and simpler to produce, is more prone to cracking and structural failure when subjected to bending or stretching forces.

Strength and Durability Analysis

Reinforced concrete significantly outperforms plain concrete in both strength and durability due to the incorporation of steel reinforcement bars, which enhance its tensile strength and resistance to cracking under stress. The composite action between concrete and steel allows reinforced concrete to withstand higher loads and longer service life in structural applications exposed to dynamic forces. Durability analysis shows that reinforced concrete maintains structural integrity better over time, especially in aggressive environments, due to the protective alkalinity of concrete that preserves steel from corrosion when properly designed.

Typical Applications of Plain Concrete

Plain concrete is commonly used in applications where high tensile strength is not required, such as sidewalks, driveways, and floor slabs. It is ideal for pavements, foundations for light structures, and non-structural elements like curbs and gutters. The cost-effectiveness and simplicity of plain concrete make it suitable for mass construction where reinforcement is unnecessary.

Common Uses for Reinforced Concrete

Reinforced concrete is widely used in structural applications requiring enhanced strength and durability, such as bridges, high-rise buildings, and industrial structures. Its embedded steel reinforcement allows it to withstand tensile stresses, making it ideal for foundations, beams, slabs, and columns. Compared to plain concrete, reinforced concrete is preferred in infrastructure projects where load-bearing capacity and crack resistance are critical.

Cost Implications: Reinforced vs Plain Concrete

Reinforced concrete typically incurs higher initial costs due to the inclusion of steel bars or mesh, which enhances tensile strength and structural durability. Plain concrete, while more economical upfront, may involve increased maintenance expenses over time because of its lower resistance to cracking and tensile stress. Cost efficiency of each varies based on project scale and structural requirements, with reinforced concrete often proving more cost-effective in long-term infrastructure applications.

Installation Methods and Labor Requirements

Reinforced concrete installation requires precise placement of steel rebar or mesh before pouring the concrete, demanding skilled labor to ensure structural integrity and proper bonding. Plain concrete involves simpler formwork and pouring techniques, resulting in faster installation and lower labor costs due to the absence of reinforcement handling. The complexity of rebar tying, positioning, and inspection significantly increases the labor intensity and installation time for reinforced concrete compared to plain concrete.

Long-Term Maintenance and Performance

Reinforced concrete exhibits superior long-term durability compared to plain concrete due to embedded steel reinforcement that enhances tensile strength and crack resistance. However, reinforcement corrosion can compromise structural integrity if not properly maintained, necessitating regular inspections and protective treatments. Plain concrete requires less maintenance but has lower tensile capacity and is more prone to cracking, impacting its longevity in structural applications.

Choosing the Right Type for Your Project

Reinforced concrete contains steel bars or mesh embedded to enhance tensile strength, making it ideal for structural elements like beams, columns, and slabs that bear heavy loads. Plain concrete offers excellent compressive strength and is suitable for non-structural applications such as sidewalks, driveways, and flooring where tensile stresses are minimal. Selecting between reinforced and plain concrete depends on the project's load requirements, durability needs, and environmental exposure conditions.

Reinforced concrete vs plain concrete Infographic

materialdif.com

materialdif.com