Self-consolidating concrete (SCC) offers superior flowability and eliminates the need for mechanical vibration, resulting in faster placement and reduced labor costs compared to conventional concrete. Its enhanced workability and ability to fill complex forms improve structural integrity and surface finish without compromising strength or durability. Conventional concrete requires vibration to remove air pockets, which can increase the risk of honeycombing and inconsistent compaction, especially in intricate or congested reinforcement areas.

Table of Comparison

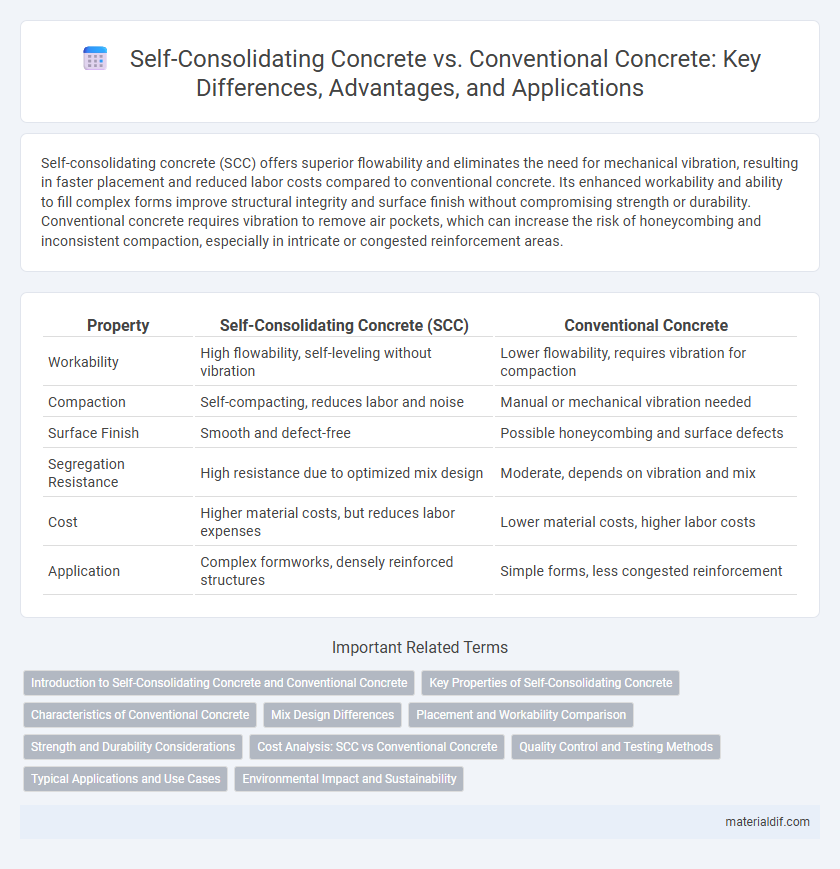

| Property | Self-Consolidating Concrete (SCC) | Conventional Concrete |

|---|---|---|

| Workability | High flowability, self-leveling without vibration | Lower flowability, requires vibration for compaction |

| Compaction | Self-compacting, reduces labor and noise | Manual or mechanical vibration needed |

| Surface Finish | Smooth and defect-free | Possible honeycombing and surface defects |

| Segregation Resistance | High resistance due to optimized mix design | Moderate, depends on vibration and mix |

| Cost | Higher material costs, but reduces labor expenses | Lower material costs, higher labor costs |

| Application | Complex formworks, densely reinforced structures | Simple forms, less congested reinforcement |

Introduction to Self-Consolidating Concrete and Conventional Concrete

Self-consolidating concrete (SCC) is a highly flowable, non-segregating concrete that spreads into place, filling formwork and encapsulating reinforcement without mechanical vibration. Conventional concrete requires vibration to remove air voids and ensure compaction, often leading to inconsistent finishes and increased labor. SCC improves construction speed, surface quality, and reduces noise and labor costs compared to traditional concrete methods.

Key Properties of Self-Consolidating Concrete

Self-Consolidating Concrete (SCC) exhibits exceptional flowability and high deformability, allowing it to fill complex formworks without mechanical vibration. The key properties of SCC include superior segregation resistance, high viscosity to maintain uniformity, and enhanced cohesiveness, which ensure stability during placement. These characteristics result in improved surface finish, reduced labor costs, and faster construction cycles compared to conventional concrete.

Characteristics of Conventional Concrete

Conventional concrete typically consists of cement, water, fine and coarse aggregates, with a water-cement ratio ranging from 0.4 to 0.6, providing adequate strength and durability for most structural applications. It requires mechanical vibration for compaction to eliminate air voids, ensuring proper density and uniformity but can be labor-intensive and prone to segregation if not mixed or placed correctly. The workability of conventional concrete varies depending on the mixture proportions, often demanding adjustments for specific construction needs while maintaining a balance between flowability and strength.

Mix Design Differences

Self-consolidating concrete (SCC) features a high flowability mix design achieved through increased fine materials, superplasticizers, and viscosity-modifying admixtures, enabling it to fill molds without mechanical vibration. Conventional concrete relies on a balanced aggregate gradation and lower water-to-cement ratio, requiring vibration for compaction and minimizing segregation. SCC's optimized particle packing and admixture dosage enhance workability and reduce segregation risk, distinguishing its mix design from traditional concrete formulations.

Placement and Workability Comparison

Self-consolidating concrete (SCC) offers superior workability compared to conventional concrete, allowing it to flow and fill formwork without mechanical vibration. The high deformability and viscosity of SCC enable faster and more uniform placement, reducing labor and minimizing voids or honeycombing. Conventional concrete requires significant vibration efforts to achieve compaction, often leading to increased time and inconsistent quality during placement.

Strength and Durability Considerations

Self-consolidating concrete (SCC) exhibits higher compressive strength and improved durability compared to conventional concrete due to its enhanced flowability and uniform compaction without mechanical vibration. The dense microstructure of SCC reduces permeability, minimizing the risk of corrosion and increasing resistance to chemical attacks, freeze-thaw cycles, and abrasion. Conventional concrete often requires vibration to achieve similar strength, but inconsistent consolidation can lead to voids, negatively impacting long-term durability and structural performance.

Cost Analysis: SCC vs Conventional Concrete

Self-consolidating concrete (SCC) often incurs higher initial material costs compared to conventional concrete due to specialized admixtures and mix design requirements. However, SCC reduces labor expenses and accelerates project timelines by eliminating the need for mechanical vibration and extensive compaction. When factoring in total project costs, including labor savings and improved quality, SCC can offer competitive or lower overall expenditures compared to traditional concrete methods.

Quality Control and Testing Methods

Self-consolidating concrete (SCC) requires rigorous quality control measures including flowability, passing ability, and segregation resistance tests to ensure uniform consistency and high performance without vibration. Conventional concrete relies heavily on slump tests and compressive strength evaluations to verify workability and structural integrity, which may not detect issues like segregation as effectively as SCC testing protocols. Advanced rheology measurements and visual stability index (VSI) assessments are critical in SCC quality control, providing superior precision compared to traditional testing methods used for conventional concrete.

Typical Applications and Use Cases

Self-consolidating concrete is widely used in complex formworks, high-rise buildings, and infrastructure projects requiring rapid placement without vibration, improving efficiency and surface finish. Conventional concrete remains preferred for applications with straightforward formworks or where cost constraints dominate, often used in pavements, foundations, and mass concrete structures. The superior flowability of self-consolidating concrete supports precast elements and intricate architectural designs, while conventional concrete suits traditional construction scenarios.

Environmental Impact and Sustainability

Self-consolidating concrete (SCC) reduces environmental impact by minimizing cement content and enhancing workability without mechanical vibration, leading to lower energy consumption on-site compared to conventional concrete. SCC promotes sustainability through reduced material wastage and improved durability, extending the lifespan of structures and decreasing the need for repairs and replacements. Conventional concrete typically requires more energy-intensive compaction methods and generates higher emissions, making SCC a more eco-friendly choice in green construction practices.

Self-Consolidating Concrete vs Conventional Concrete Infographic

materialdif.com

materialdif.com