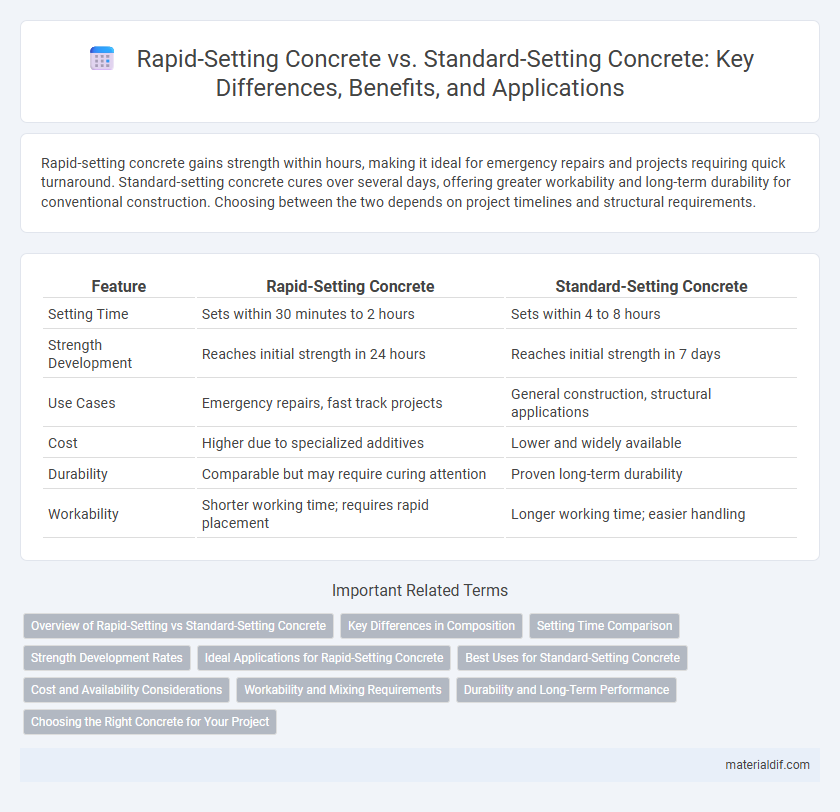

Rapid-setting concrete gains strength within hours, making it ideal for emergency repairs and projects requiring quick turnaround. Standard-setting concrete cures over several days, offering greater workability and long-term durability for conventional construction. Choosing between the two depends on project timelines and structural requirements.

Table of Comparison

| Feature | Rapid-Setting Concrete | Standard-Setting Concrete |

|---|---|---|

| Setting Time | Sets within 30 minutes to 2 hours | Sets within 4 to 8 hours |

| Strength Development | Reaches initial strength in 24 hours | Reaches initial strength in 7 days |

| Use Cases | Emergency repairs, fast track projects | General construction, structural applications |

| Cost | Higher due to specialized additives | Lower and widely available |

| Durability | Comparable but may require curing attention | Proven long-term durability |

| Workability | Shorter working time; requires rapid placement | Longer working time; easier handling |

Overview of Rapid-Setting vs Standard-Setting Concrete

Rapid-setting concrete achieves strength in 3 to 6 hours due to its high cementitious content and chemical accelerators, making it ideal for emergency repairs and fast track construction projects. Standard-setting concrete typically gains initial set around 4 to 6 hours and reaches full strength in 28 days, offering long-term durability and structural integrity for conventional applications. Differences in curing time, strength development, and mix composition dictate the choice between rapid-setting and standard-setting concrete based on project timeline and performance requirements.

Key Differences in Composition

Rapid-setting concrete contains high aluminate cement and accelerators such as calcium chloride, which significantly reduces setting time to under an hour, compared to standard-setting concrete's use of ordinary Portland cement that sets within 24 hours. The chemical composition of rapid-setting concrete promotes faster hydration reactions, resulting in early strength gain, while standard-setting concrete achieves strength more gradually due to slower cement hydration. Aggregate gradation and admixtures also differ, with rapid-setting formulations optimized for quick strength development and durability in time-sensitive projects.

Setting Time Comparison

Rapid-setting concrete achieves initial set within 30 minutes to 2 hours, significantly faster than standard-setting concrete, which typically requires 4 to 8 hours. This accelerated setting time allows for quicker formwork removal and faster project progression in time-sensitive applications. The faster hydration process in rapid-setting concrete is due to specialized additives like calcium chloride or aluminate cements.

Strength Development Rates

Rapid-setting concrete achieves substantial strength within hours, often reaching 3,000 psi in as little as 6 hours, making it ideal for time-sensitive projects and urgent repairs. Standard-setting concrete typically reaches similar strength levels after 28 days, following a gradual hydration process that ensures long-term durability. The accelerated curing of rapid-setting concrete results from its higher cement fineness and the inclusion of chemical accelerators, significantly enhancing early strength development compared to traditional mixes.

Ideal Applications for Rapid-Setting Concrete

Rapid-setting concrete is ideal for urgent repair projects, such as highway patching, emergency structural repairs, and cold-weather concreting where fast strength gain is critical. Its quick hardening properties enable minimal downtime for infrastructure and commercial flooring, ensuring faster reopening of roads and facilities. This type of concrete is preferred in situations demanding immediate load-bearing capacity and accelerated construction schedules.

Best Uses for Standard-Setting Concrete

Standard-setting concrete is ideal for large-scale construction projects such as highways, bridges, and commercial buildings where extended workability and curing time are crucial. Its slower setting time allows for better handling, shaping, and finishing, ensuring structural integrity and durability over time. This type also accommodates adjustments and makes it suitable for applications requiring precision and stability in varying environmental conditions.

Cost and Availability Considerations

Rapid-setting concrete generally incurs higher upfront costs due to specialized additives but reduces labor and downtime expenses, offering potential overall project savings. Standard-setting concrete is more widely available and cost-effective for bulk purchases, making it suitable for large-scale projects with flexible timelines. Availability of rapid-setting mixes may be limited in some regions, influencing project scheduling and logistics.

Workability and Mixing Requirements

Rapid-setting concrete requires precise water-to-cement ratios and immediate mixing to ensure proper workability, as its quick setting time reduces the margin for adjustments. Standard-setting concrete offers more flexibility in mixing and longer workability periods, allowing for extended placement and finishing times. Proper admixture selection is crucial in rapid-setting concrete to maintain flowability without compromising its accelerated curing process.

Durability and Long-Term Performance

Rapid-setting concrete achieves high early strength, enabling faster construction cycles but may exhibit slightly reduced long-term durability compared to standard-setting concrete, which gains strength more gradually and offers enhanced resistance to environmental stressors and cracking. Standard-setting concrete's dense microstructure provides superior performance in harsh conditions, extending the lifespan of infrastructure components exposed to freeze-thaw cycles, chemical attack, and heavy loads. Choosing between rapid- and standard-setting concrete depends on balancing project timelines with the required longevity and durability of the structure.

Choosing the Right Concrete for Your Project

Rapid-setting concrete cures in as little as 20 to 40 minutes, making it ideal for urgent repairs and projects requiring quick turnaround, whereas standard-setting concrete typically sets within 24 to 48 hours, providing greater workability for larger or more complex structures. Selecting the right concrete depends on project timelines, environmental conditions, and load-bearing requirements, with rapid-setting formulas suited for cold weather and fast traffic return, while standard-setting options offer extended finishing times and enhanced strength development. Engineers prioritize rapid-setting concrete for emergency patching and winter applications, while standard-setting concrete is preferred for slabs, foundations, and long-term durability.

Rapid-Setting Concrete vs Standard-Setting Concrete Infographic

materialdif.com

materialdif.com