Cementitious grout offers excellent compressive strength and is breathable, making it suitable for outdoor concrete pet structures where moisture management is crucial. Epoxy grout provides superior chemical resistance and durability, ideal for indoor pet areas exposed to stains and frequent cleaning. Choosing between the two depends on environmental conditions and maintenance requirements of the concrete pet installations.

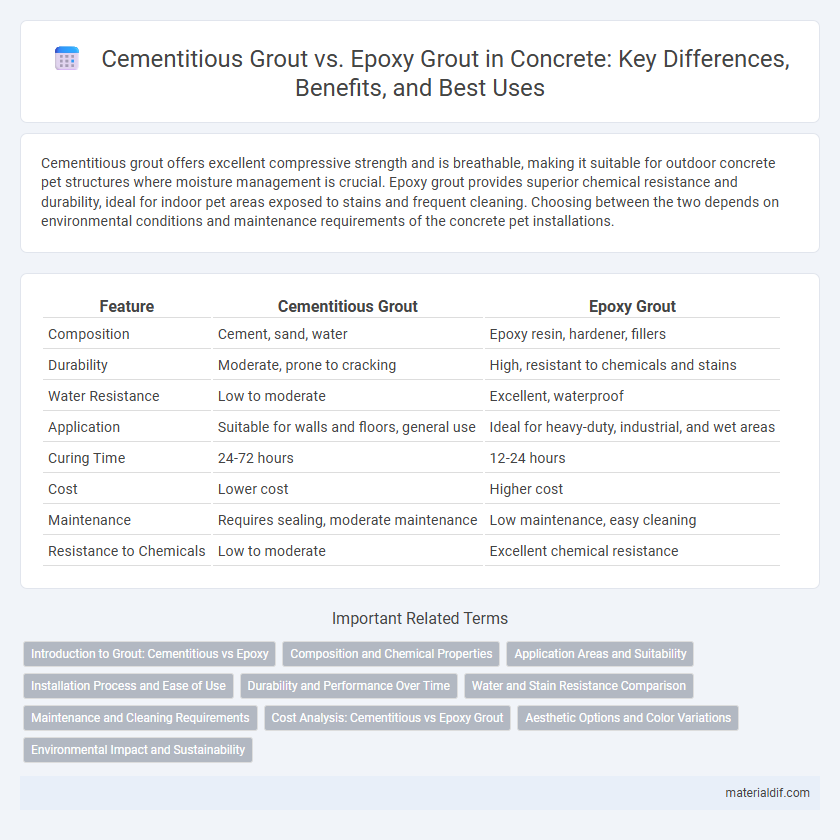

Table of Comparison

| Feature | Cementitious Grout | Epoxy Grout |

|---|---|---|

| Composition | Cement, sand, water | Epoxy resin, hardener, fillers |

| Durability | Moderate, prone to cracking | High, resistant to chemicals and stains |

| Water Resistance | Low to moderate | Excellent, waterproof |

| Application | Suitable for walls and floors, general use | Ideal for heavy-duty, industrial, and wet areas |

| Curing Time | 24-72 hours | 12-24 hours |

| Cost | Lower cost | Higher cost |

| Maintenance | Requires sealing, moderate maintenance | Low maintenance, easy cleaning |

| Resistance to Chemicals | Low to moderate | Excellent chemical resistance |

Introduction to Grout: Cementitious vs Epoxy

Cementitious grout is a water-based mixture of cement, sand, and water, offering excellent compressive strength and ease of application for standard tile installations. Epoxy grout, composed of epoxy resins and a filler powder, provides superior chemical resistance, stain resistance, and durability in high-traffic or moisture-prone areas. Selecting between cementitious and epoxy grout depends on project requirements such as exposure to chemicals, moisture, and mechanical stress.

Composition and Chemical Properties

Cementitious grout is primarily composed of a mixture of cement, water, and fine aggregates, offering high porosity and moderate chemical resistance, making it suitable for general construction applications. Epoxy grout consists of epoxy resins and hardeners, creating a dense, non-porous matrix with superior chemical resistance and high tensile strength, ideal for environments exposed to harsh chemicals or heavy loads. Due to its polymer-based composition, epoxy grout exhibits excellent adhesion and stain resistance compared to the more absorbent and brittle nature of cementitious grout.

Application Areas and Suitability

Cementitious grout is ideal for filling wider joints in floor tiles, masonry, and swimming pools due to its permeability and ease of application, making it suitable for interior and exterior use. Epoxy grout offers superior chemical resistance and durability, making it perfect for areas exposed to heavy traffic, moisture, and harsh chemicals, such as commercial kitchens, hospitals, and industrial flooring. While cementitious grout is cost-effective and easier to repair, epoxy grout excels in high-performance applications requiring long-term integrity and stain resistance.

Installation Process and Ease of Use

Cementitious grout requires thorough mixing and careful water ratio control to achieve optimal consistency, often necessitating experienced labor for proper installation. Epoxy grout offers a faster installation process with minimal water needed, providing superior adhesion and resistance to stains, but demands precise application techniques to avoid gaps and bubbles. Both types benefit from clean substrate preparation, yet epoxy grout's chemical cure allows for quicker setting times and enhanced durability in challenging conditions.

Durability and Performance Over Time

Cementitious grout offers moderate durability and is prone to cracking and shrinking over time, especially in high-moisture environments. Epoxy grout provides superior performance with exceptional resistance to stains, chemicals, and water, maintaining its integrity and color even under heavy traffic and harsh conditions. For long-term applications requiring high durability and minimal maintenance, epoxy grout consistently outperforms cementitious grout.

Water and Stain Resistance Comparison

Cementitious grout typically absorbs more water, leading to increased vulnerability to stains and moisture damage compared to epoxy grout. Epoxy grout, composed of resin and hardeners, offers superior water resistance and remarkable stain repellency, making it ideal for wet or high-traffic areas. The enhanced chemical resistance of epoxy grout also ensures long-term durability against harsh cleaning agents and contaminants.

Maintenance and Cleaning Requirements

Cementitious grout requires regular sealing and frequent cleaning with pH-neutral cleaners to prevent staining and deterioration, making maintenance more labor-intensive. Epoxy grout is highly resistant to stains, chemicals, and moisture, allowing for easier cleaning with mild detergents and reducing the need for resealing. The durability and non-porous nature of epoxy grout significantly lower the overall maintenance and cleaning efforts compared to cementitious grout.

Cost Analysis: Cementitious vs Epoxy Grout

Cementitious grout generally costs less than epoxy grout, making it a more budget-friendly option for large-scale projects requiring extensive application. Epoxy grout, despite its higher initial price, offers superior durability, chemical resistance, and stain prevention, which can reduce long-term maintenance expenses. Considering lifecycle costs, epoxy grout often provides better value in environments exposed to heavy traffic or corrosive substances.

Aesthetic Options and Color Variations

Cementitious grout offers a broad range of natural, earthy color variations that blend seamlessly with stone and ceramic tiles, enhancing rustic and traditional aesthetics. Epoxy grout provides superior color consistency and vibrant, easily customizable hues that resist staining and fading, ideal for modern and high-traffic areas. Both grout types present unique aesthetic options, with epoxy enabling polished, long-lasting finishes and cementitious grout allowing more organic, matte appearances.

Environmental Impact and Sustainability

Cementitious grout, composed of natural materials like cement, sand, and water, exhibits lower embodied energy and is generally more sustainable due to its biodegradability and easier recyclability. In contrast, epoxy grout contains synthetic resins and hardeners derived from petrochemicals, leading to higher carbon emissions during production and challenging disposal processes. Choosing cementitious grout supports reduced environmental impact through decreased chemical pollutants and enhanced ecological compatibility.

Cementitious Grout vs Epoxy Grout Infographic

materialdif.com

materialdif.com