Fly ash and slag are both supplementary cementitious materials used to enhance concrete performance by improving strength, durability, and workability. Fly ash, a byproduct of coal combustion in power plants, typically produces a smoother, more workable concrete with reduced heat of hydration, while slag, derived from iron production, contributes to higher early strength and better resistance to chemical attack. Selecting between fly ash and slag depends on specific project requirements such as strength development, environmental conditions, and sustainability goals.

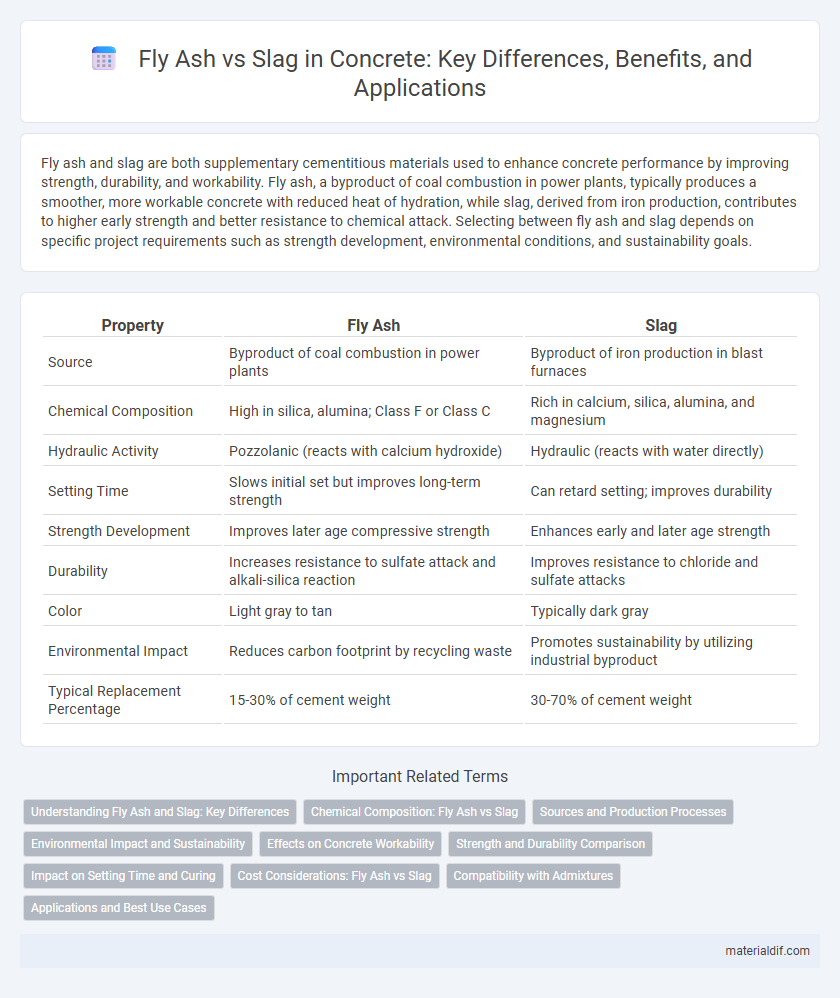

Table of Comparison

| Property | Fly Ash | Slag |

|---|---|---|

| Source | Byproduct of coal combustion in power plants | Byproduct of iron production in blast furnaces |

| Chemical Composition | High in silica, alumina; Class F or Class C | Rich in calcium, silica, alumina, and magnesium |

| Hydraulic Activity | Pozzolanic (reacts with calcium hydroxide) | Hydraulic (reacts with water directly) |

| Setting Time | Slows initial set but improves long-term strength | Can retard setting; improves durability |

| Strength Development | Improves later age compressive strength | Enhances early and later age strength |

| Durability | Increases resistance to sulfate attack and alkali-silica reaction | Improves resistance to chloride and sulfate attacks |

| Color | Light gray to tan | Typically dark gray |

| Environmental Impact | Reduces carbon footprint by recycling waste | Promotes sustainability by utilizing industrial byproduct |

| Typical Replacement Percentage | 15-30% of cement weight | 30-70% of cement weight |

Understanding Fly Ash and Slag: Key Differences

Fly ash, a byproduct of coal combustion, improves concrete strength and durability by enhancing workability and reducing permeability, while slag, derived from recycled iron blast furnace residue, provides superior resistance to chemical attack and contributes to concrete's long-term strength. Both materials are used as supplementary cementitious materials (SCMs) but differ in chemical composition, with fly ash primarily consisting of silica and alumina, and slag rich in calcium and magnesium oxides. The choice between fly ash and slag depends on project requirements such as setting time, environmental exposure, and desired mechanical properties.

Chemical Composition: Fly Ash vs Slag

Fly ash primarily consists of silica (SiO2), alumina (Al2O3), and smaller amounts of iron oxide (Fe2O3) and calcium oxide (CaO), contributing to its pozzolanic properties. Slag, specifically ground granulated blast furnace slag (GGBFS), contains higher calcium oxide content alongside silica and alumina, promoting hydraulic cementitious reactions. The elevated CaO in slag accelerates strength development, whereas fly ash's lower CaO content results in slower but long-term beneficial binding characteristics in concrete.

Sources and Production Processes

Fly ash is a byproduct of coal combustion produced in thermal power plants, consisting mainly of silica, alumina, and iron oxides formed from the fine particles carried by flue gases. Slag, specifically ground granulated blast-furnace slag (GGBFS), originates from the molten iron and slag produced during the steel manufacturing process, which is rapidly cooled with water to form a glassy granular material. Both materials serve as supplementary cementitious substances, enhancing concrete durability and sustainability by utilizing industrial byproducts from power generation and steel production.

Environmental Impact and Sustainability

Fly ash, a byproduct of coal combustion, reduces landfill waste and lowers concrete's carbon footprint by partially replacing cement, which requires high energy for production. Slag, derived from iron production, improves concrete durability and reduces greenhouse gas emissions due to its lower embodied energy compared to Portland cement. Both materials contribute to sustainable construction by enhancing resource efficiency and minimizing environmental impact in concrete manufacturing.

Effects on Concrete Workability

Fly ash improves concrete workability by enhancing its flow and reducing water demand due to its spherical particle shape, resulting in smoother application and easier placement. Slag also contributes to workability but to a lesser extent, as its angular particles can increase water demand and require admixtures for comparable fluidity. Both materials enhance concrete's cohesiveness, but fly ash is generally preferred for applications requiring superior plasticity and pumpability.

Strength and Durability Comparison

Fly ash concrete exhibits improved long-term strength due to its pozzolanic reaction that enhances the calcium silicate hydrate matrix, resulting in denser microstructure and reduced permeability. Slag concrete offers superior durability by providing higher resistance to sulfate attack and chloride ion penetration, which significantly lowers the risk of reinforcement corrosion. Both materials contribute to increased concrete durability, but slag typically outperforms fly ash in aggressive chemical environments, while fly ash excels in enhancing workability and late-age strength development.

Impact on Setting Time and Curing

Fly ash typically slows the setting time of concrete due to its pozzolanic reaction, which enhances long-term strength and durability by refining the microstructure during curing. Slag, a hydraulic binder, accelerates setting and improves early strength gain by reacting quickly with water and cement compounds. Optimizing the blend of fly ash and slag can balance setting time and curing performance, enhancing workability and final concrete properties.

Cost Considerations: Fly Ash vs Slag

Fly ash generally offers a cost advantage over slag due to its more abundant availability and lower processing expenses, making it a preferred supplementary cementitious material in many concrete applications. Slag, derived from iron production, often incurs higher transportation and processing costs, which can increase overall project expenses despite its superior durability benefits. Project budgets must weigh these cost differences against performance requirements to determine the most economical choice for concrete mix design.

Compatibility with Admixtures

Fly ash exhibits high compatibility with most concrete admixtures, including superplasticizers and air-entraining agents, enhancing workability and durability. Slag, particularly ground granulated blast-furnace slag (GGBFS), also works well with admixtures but may require adjustments in dosage to control setting time and strength development. Both materials contribute to improved cement hydration and reduced permeability when properly integrated with chemical additives.

Applications and Best Use Cases

Fly ash, a byproduct of coal combustion, is commonly used in concrete to improve workability, reduce water demand, and enhance durability, making it ideal for mass concrete structures and high-performance applications. Slag, a byproduct of iron production, excels in producing low-heat, sulfate-resistant concrete, making it suitable for marine structures, sewage treatment plants, and environments exposed to aggressive chemicals. Combining fly ash and slag can optimize concrete properties for specific construction needs, balancing strength development and durability in large-scale infrastructure projects.

Fly ash vs slag Infographic

materialdif.com

materialdif.com