Pozzolanic materials, such as fly ash and silica fume, react chemically with calcium hydroxide in concrete to form additional cementitious compounds, enhancing strength and durability. Non-pozzolanic materials, like inert sand or gravel, do not participate in chemical reactions but serve mainly as aggregates to provide volume and stability. Incorporating pozzolanic materials improves resistance to sulfate attack, reduces permeability, and lowers heat of hydration compared to non-pozzolanic constituents.

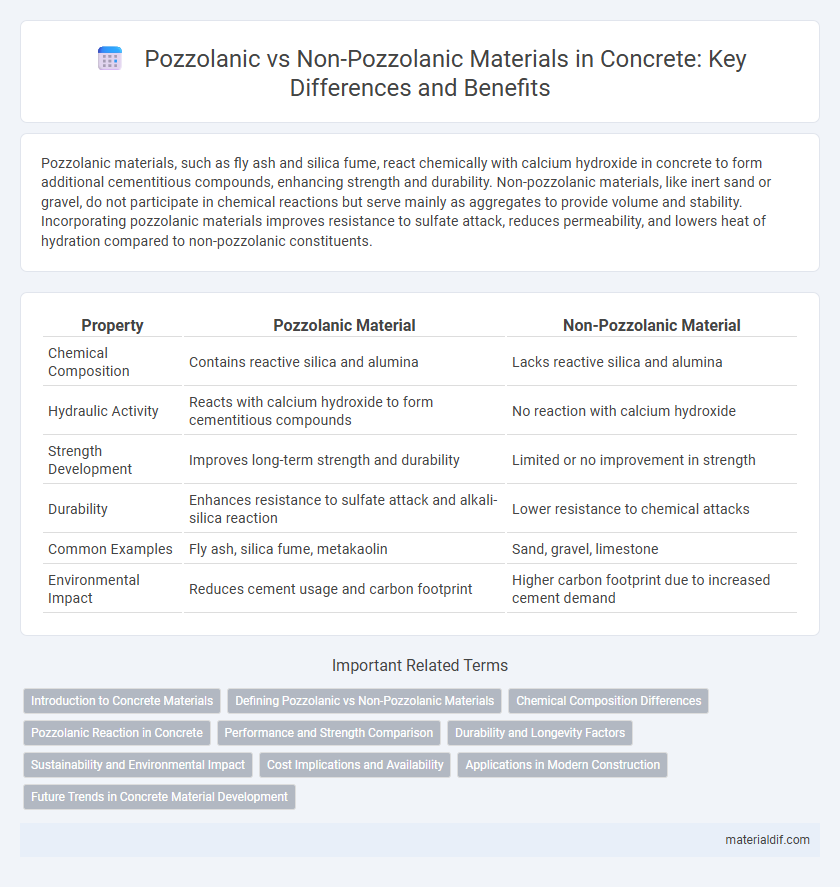

Table of Comparison

| Property | Pozzolanic Material | Non-Pozzolanic Material |

|---|---|---|

| Chemical Composition | Contains reactive silica and alumina | Lacks reactive silica and alumina |

| Hydraulic Activity | Reacts with calcium hydroxide to form cementitious compounds | No reaction with calcium hydroxide |

| Strength Development | Improves long-term strength and durability | Limited or no improvement in strength |

| Durability | Enhances resistance to sulfate attack and alkali-silica reaction | Lower resistance to chemical attacks |

| Common Examples | Fly ash, silica fume, metakaolin | Sand, gravel, limestone |

| Environmental Impact | Reduces cement usage and carbon footprint | Higher carbon footprint due to increased cement demand |

Introduction to Concrete Materials

Pozzolanic materials, such as fly ash and silica fume, react chemically with calcium hydroxide in concrete to form additional calcium silicate hydrate, enhancing strength and durability. Non-pozzolanic materials, like limestone aggregate or typical sands, do not contribute to this chemical reaction and primarily serve as inert fillers. Understanding the distinctions between these materials is essential for optimizing concrete mix design and improving performance characteristics.

Defining Pozzolanic vs Non-Pozzolanic Materials

Pozzolanic materials are siliceous or aluminous substances that, when mixed with calcium hydroxide and water, chemically react to form compounds possessing cementitious properties, enhancing the strength and durability of concrete. Non-pozzolanic materials do not exhibit this chemical reactivity and primarily act as inert fillers within the concrete mix, contributing limited improvements to mechanical properties. Key examples of pozzolanic materials include fly ash, silica fume, and metakaolin, while typical non-pozzolanic materials encompass sand and gravel.

Chemical Composition Differences

Pozzolanic materials contain significant amounts of silica (SiO2) and alumina (Al2O3) that react chemically with calcium hydroxide in the presence of moisture to form cementitious compounds, enhancing concrete strength and durability. Non-pozzolanic materials typically lack reactive silica and alumina, consisting mainly of inert substances like quartz or limestone, which do not contribute to the chemical hydration process. The key chemical difference lies in the presence of amorphous or reactive phases in pozzolanic materials that facilitate the formation of calcium silicate hydrate (C-S-H) gel compared to the largely inert composition of non-pozzolanic materials.

Pozzolanic Reaction in Concrete

Pozzolanic materials in concrete, such as fly ash and silica fume, react chemically with calcium hydroxide to form additional calcium silicate hydrate (C-S-H), which enhances the strength and durability of the concrete. This pozzolanic reaction improves concrete's resistance to chemical attack, reduces permeability, and mitigates alkali-silica reaction (ASR) risks. Non-pozzolanic materials do not chemically react with calcium hydroxide, thus providing mainly physical filler effects without contributing to the long-term strength development.

Performance and Strength Comparison

Pozzolanic materials such as fly ash and silica fume significantly enhance concrete performance by improving durability, reducing permeability, and increasing long-term strength through their chemical reaction with calcium hydroxide. Non-pozzolanic materials lack these reactive properties, resulting in lower strength gain and higher susceptibility to environmental degradation. Incorporating pozzolanic additives leads to superior compressive strength and improved resistance to sulfate attack compared to concrete with only non-pozzolanic aggregates or fillers.

Durability and Longevity Factors

Pozzolanic materials, such as fly ash and silica fume, significantly enhance the durability and longevity of concrete by reducing permeability and improving resistance to chemical attacks like sulfate and chloride ingress. Non-pozzolanic materials typically lack these reactive properties, resulting in concrete that is more susceptible to cracking and degradation over time. The inclusion of pozzolanic additives optimizes the microstructure, promoting long-term strength and durability in aggressive environments.

Sustainability and Environmental Impact

Pozzolanic materials, such as fly ash and silica fume, enhance concrete durability and reduce cement consumption, significantly lowering CO2 emissions compared to non-pozzolanic materials like standard aggregates. Their ability to react with calcium hydroxide improves long-term strength and impermeability, minimizing resource depletion and waste generation. Incorporating pozzolanic materials supports sustainable construction by promoting energy efficiency and reducing the carbon footprint of concrete production.

Cost Implications and Availability

Pozzolanic materials such as fly ash and silica fume are often more cost-effective due to their industrial by-product nature and abundant availability, reducing raw material expenses in concrete production. Non-pozzolanic materials, primarily traditional Portland cement, tend to have higher costs linked to energy-intensive manufacturing and finite raw material sources. The widespread availability of pozzolanic materials can fluctuate regionally, impacting project budgets, whereas non-pozzolanic cement remains consistently accessible globally but at a generally higher price point.

Applications in Modern Construction

Pozzolanic materials, such as fly ash and silica fume, are widely used in modern construction to enhance concrete durability, reduce permeability, and improve resistance to chemical attacks. Non-pozzolanic materials, like traditional sand and gravel, primarily serve as aggregates without contributing to the chemical strength or long-term performance of concrete. The integration of pozzolanic materials in concrete formulations supports sustainable building practices by utilizing industrial by-products and lowering cement consumption.

Future Trends in Concrete Material Development

Future trends in concrete material development emphasize the integration of pozzolanic materials such as fly ash, silica fume, and metakaolin to enhance sustainability and performance by improving strength, durability, and reducing carbon footprint. Non-pozzolanic materials, primarily traditional aggregates and Portland cement, face challenges due to higher CO2 emissions and lower environmental benefits. Innovations focus on optimizing pozzolanic reactions to create eco-friendly, high-performance concrete with enhanced resistance to chemical attack and improved long-term mechanical properties.

Pozzolanic material vs non-pozzolanic material Infographic

materialdif.com

materialdif.com