Ready-mix concrete offers consistent quality and precise mix proportions controlled at a batching plant, ensuring faster application and reduced labor costs compared to site-mix concrete. Site-mix concrete allows for on-demand mixing tailored to specific project needs but often results in variable quality due to manual measurements and environmental factors. Choosing between ready-mix and site-mix depends on project size, required strength, and logistical considerations.

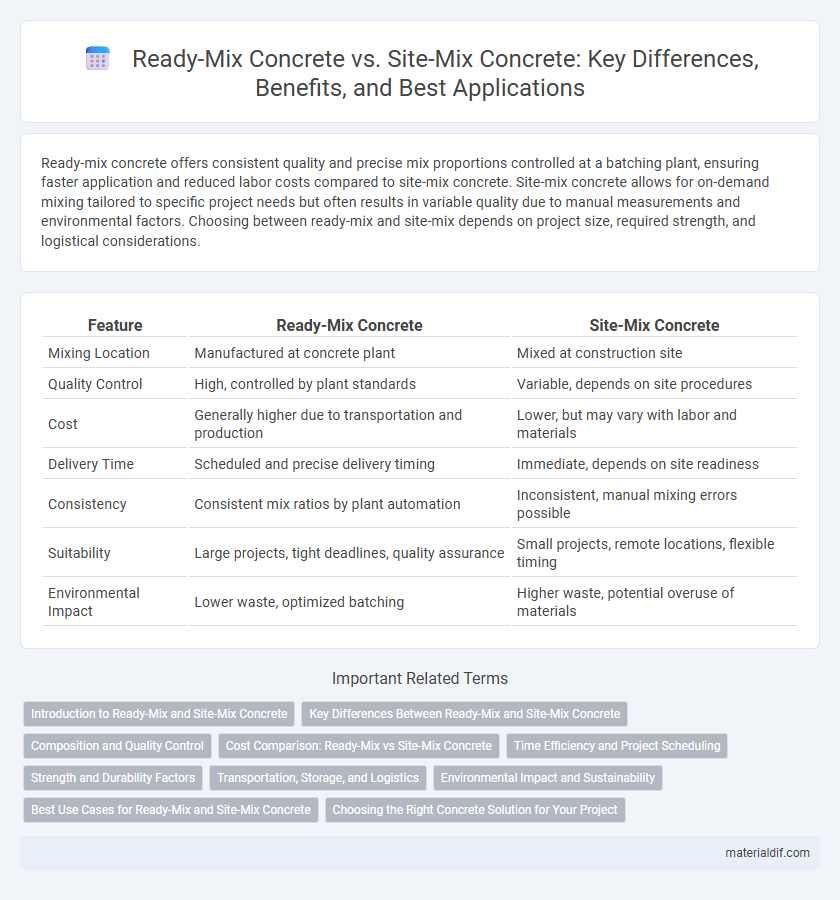

Table of Comparison

| Feature | Ready-Mix Concrete | Site-Mix Concrete |

|---|---|---|

| Mixing Location | Manufactured at concrete plant | Mixed at construction site |

| Quality Control | High, controlled by plant standards | Variable, depends on site procedures |

| Cost | Generally higher due to transportation and production | Lower, but may vary with labor and materials |

| Delivery Time | Scheduled and precise delivery timing | Immediate, depends on site readiness |

| Consistency | Consistent mix ratios by plant automation | Inconsistent, manual mixing errors possible |

| Suitability | Large projects, tight deadlines, quality assurance | Small projects, remote locations, flexible timing |

| Environmental Impact | Lower waste, optimized batching | Higher waste, potential overuse of materials |

Introduction to Ready-Mix and Site-Mix Concrete

Ready-mix concrete is pre-manufactured in a batching plant according to specific mix designs and delivered to construction sites in a fresh, workable state, ensuring consistent quality and precise proportions. Site-mix concrete is produced directly on the construction site by mixing cement, aggregates, water, and additives manually or with portable mixers, allowing flexibility but often leading to variability in strength and durability. Ready-mix concrete optimizes efficiency and uniformity, while site-mix concrete offers adaptability for smaller or remote projects.

Key Differences Between Ready-Mix and Site-Mix Concrete

Ready-mix concrete is manufactured in a centralized plant under controlled conditions, ensuring consistent quality, precise mix proportions, and time-efficient delivery to construction sites. Site-mix concrete is mixed manually on-site, often leading to variability in composition, inconsistent strength, and extended labor time due to manual batching and mixing processes. Key differences include consistency, quality control, labor costs, and convenience, with ready-mix concrete preferred for large-scale projects and site-mix used in smaller or remote locations where plant access is limited.

Composition and Quality Control

Ready-mix concrete is produced in a controlled factory environment with precise measurements of cement, water, aggregates, and admixtures, ensuring consistent quality and optimal strength. Site-mix concrete, on the other hand, is mixed on-site with varying proportions and manual processes, leading to potential inconsistencies in composition and reduced durability. Quality control in ready-mix concrete involves strict testing and mechanized batching, whereas site-mix concrete relies heavily on operator skill and local material quality.

Cost Comparison: Ready-Mix vs Site-Mix Concrete

Ready-mix concrete typically incurs higher initial costs due to batching, mixing, and transportation but reduces labor and material wastage on-site, leading to overall cost-efficiency for large projects. Site-mix concrete offers lower upfront expenses by using locally sourced materials and on-site mixing, but increased labor costs and inconsistent quality may raise the total project cost. Evaluating project scale, labor availability, and quality requirements is essential to determine the most cost-effective concrete solution.

Time Efficiency and Project Scheduling

Ready-mix concrete significantly improves time efficiency by delivering pre-mixed, quality-controlled material directly to the construction site, reducing onsite preparation time and minimizing project delays. Site-mix concrete requires on-site batching and mixing, which can lead to inconsistent quality and longer labor hours, complicating project scheduling. Utilizing ready-mix concrete streamlines workflow, supports tighter project timelines, and enhances overall schedule reliability.

Strength and Durability Factors

Ready-mix concrete exhibits superior strength and durability due to its precise batching and controlled mixing processes in a factory environment, ensuring consistent water-cement ratios and high-quality materials. Site-mix concrete often suffers from variability in mixing accuracy and material quality, leading to lower compressive strength and increased susceptibility to cracking and weathering. Standardized quality control in ready-mix concrete enhances long-term structural performance, making it the preferred choice for critical construction projects requiring high durability.

Transportation, Storage, and Logistics

Ready-mix concrete is delivered in a controlled environment via transit mixers, ensuring consistent quality and minimizing delays at the construction site. Site-mix concrete requires on-site batching, which demands proper storage of raw materials such as cement, aggregates, and water, increasing logistical complexity and the risk of inconsistencies. Transportation efficiency of ready-mix concrete reduces waste and labor costs, while site-mix concrete relies heavily on proximity to material sources and skilled operators to maintain optimal freshness and workability.

Environmental Impact and Sustainability

Ready-mix concrete significantly reduces environmental impact by minimizing waste and optimizing precise material batching at centralized plants, which lowers carbon emissions compared to site-mix concrete. Site-mix concrete often results in excessive material usage and increased dust and noise pollution due to on-site mixing processes, contributing to environmental degradation. Sustainable construction benefits more from ready-mix concrete through enhanced quality control and efficient resource utilization, promoting lower lifecycle carbon footprints in infrastructure projects.

Best Use Cases for Ready-Mix and Site-Mix Concrete

Ready-mix concrete is ideal for large-scale construction projects requiring precise mix proportions and rapid placement, such as commercial buildings and infrastructure, ensuring consistent quality and reducing labor on-site. Site-mix concrete suits smaller jobs, repairs, or locations with limited access, allowing flexibility in batching and immediate adjustments to the mix according to site conditions. Choosing between ready-mix and site-mix depends on project size, logistical constraints, required strength, and durability specifications.

Choosing the Right Concrete Solution for Your Project

Ready-mix concrete offers consistent quality and precise mix ratios tailored to specific project requirements, making it ideal for large-scale construction with strict quality control standards. Site-mix concrete provides flexibility for small projects or remote locations, allowing adjustments on the spot but may suffer from variable strength and curing issues due to on-site mixing inconsistencies. Selecting the right concrete solution depends on project size, quality demands, time constraints, and logistical considerations to ensure structural integrity and cost efficiency.

Ready-Mix Concrete vs Site-Mix Concrete Infographic

materialdif.com

materialdif.com