Self-compacting concrete (SCC) flows effortlessly into formworks without the need for mechanical vibration, ensuring uniform compaction and eliminating voids. Vibrated concrete requires external vibration to achieve compaction, which can be labor-intensive and may lead to inconsistent density if not properly executed. SCC offers benefits such as improved surface finish, reduced noise pollution, and faster placement, making it ideal for complex structures and congested reinforcement.

Table of Comparison

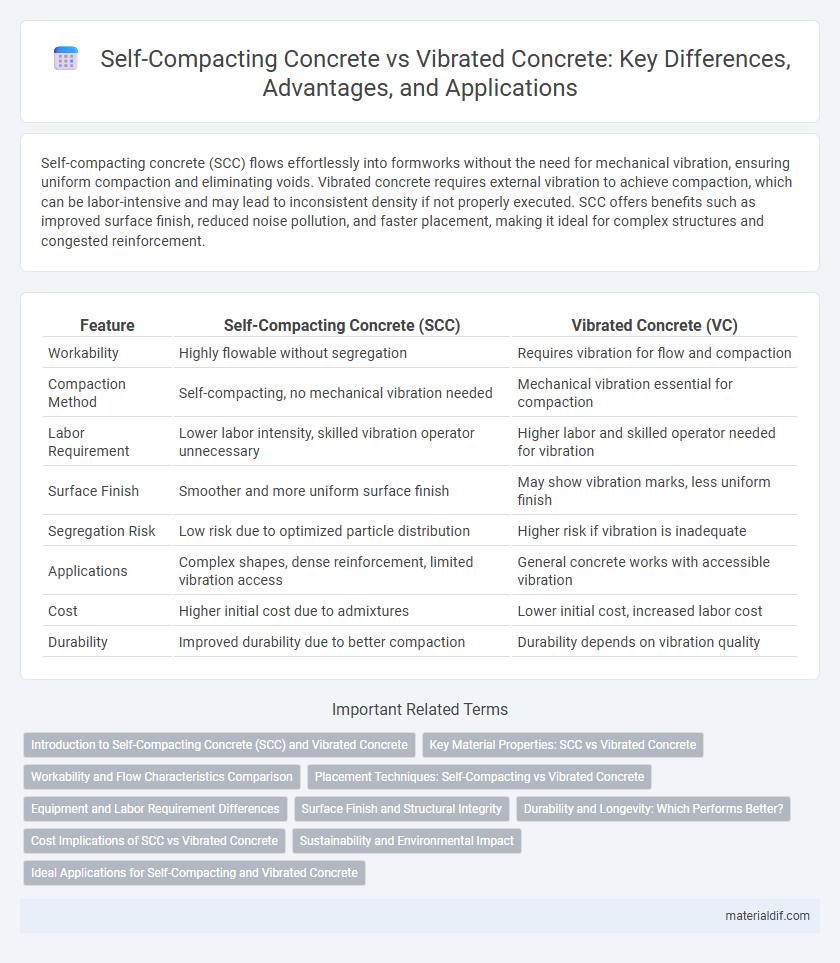

| Feature | Self-Compacting Concrete (SCC) | Vibrated Concrete (VC) |

|---|---|---|

| Workability | Highly flowable without segregation | Requires vibration for flow and compaction |

| Compaction Method | Self-compacting, no mechanical vibration needed | Mechanical vibration essential for compaction |

| Labor Requirement | Lower labor intensity, skilled vibration operator unnecessary | Higher labor and skilled operator needed for vibration |

| Surface Finish | Smoother and more uniform surface finish | May show vibration marks, less uniform finish |

| Segregation Risk | Low risk due to optimized particle distribution | Higher risk if vibration is inadequate |

| Applications | Complex shapes, dense reinforcement, limited vibration access | General concrete works with accessible vibration |

| Cost | Higher initial cost due to admixtures | Lower initial cost, increased labor cost |

| Durability | Improved durability due to better compaction | Durability depends on vibration quality |

Introduction to Self-Compacting Concrete (SCC) and Vibrated Concrete

Self-Compacting Concrete (SCC) is designed to flow under its own weight, filling formwork and encapsulating reinforcement without mechanical vibration, enhancing construction efficiency and surface finish quality. Vibrated Concrete relies on external vibration to eliminate air pockets and achieve compaction, ensuring strength and durability but requiring additional labor and equipment. SCC offers advantages in complex formworks and congested reinforcement zones, reducing noise and improving worksite safety compared to traditional vibrated concrete methods.

Key Material Properties: SCC vs Vibrated Concrete

Self-compacting concrete (SCC) offers superior flowability and fills complex formworks effortlessly without mechanical vibration, reducing labor and noise on-site. Vibrated concrete relies on external vibration to eliminate air pockets, ensuring proper compaction and high density, which affects its compressive strength and durability. SCC typically provides enhanced surface finish and uniformity, while vibrated concrete may achieve higher consolidation in structurally critical areas.

Workability and Flow Characteristics Comparison

Self-compacting concrete (SCC) exhibits superior workability and flow characteristics compared to vibrated concrete, allowing it to fill complex formworks and encapsulate reinforcement without mechanical vibration. SCC achieves a high degree of fluidity through optimized mix design incorporating superplasticizers and viscosity-modifying agents, promoting uniform flow and minimizing segregation. In contrast, vibrated concrete relies on external vibration to consolidate, which may cause inconsistent compaction and requires skilled labor, limiting its use in intricate structural elements.

Placement Techniques: Self-Compacting vs Vibrated Concrete

Self-compacting concrete (SCC) employs a flowable mix design that enables effortless placement by gravity without mechanical consolidation, reducing labor and equipment needs. Vibrated concrete requires external vibration to eliminate air pockets and achieve proper compaction, necessitating skilled operators and additional time on-site. SCC enhances uniformity and surface finish, especially in complex formworks, while vibrated concrete may face challenges in congested reinforcement areas.

Equipment and Labor Requirement Differences

Self-compacting concrete (SCC) requires minimal vibration equipment, relying on its high-flow properties to fill formwork and achieve consolidation without mechanical vibration, which significantly reduces labor intensity and expertise demand. In contrast, vibrated concrete depends on external vibrators, such as internal or external vibrators, necessitating skilled operators to ensure proper compaction and avoid defects like honeycombing. The reduced equipment needs and simplified placement of SCC contribute to faster construction cycles and lower workforce requirements compared to vibrated concrete.

Surface Finish and Structural Integrity

Self-compacting concrete (SCC) achieves a superior surface finish with smooth, uniform texture due to its flowable, non-segregating mix that fills formwork without vibration, reducing surface defects like honeycombing and air voids. Vibrated concrete relies on mechanical compaction to enhance structural integrity by consolidating the mix around reinforcement, but improper vibration can lead to surface blemishes and inconsistent finishes. Both types provide strong structural performance, yet SCC offers improved aesthetic quality and reduced labor, making it ideal for complex formworks and intricate architectural elements.

Durability and Longevity: Which Performs Better?

Self-Compacting Concrete (SCC) demonstrates superior durability and longevity compared to Vibrated Concrete due to its high flowability, allowing for better compaction without mechanical vibration, which reduces voids and microcracks. SCC's homogenous mix ensures enhanced resistance to environmental stressors such as freeze-thaw cycles, chemical attacks, and chloride penetration, contributing to extended service life. Conversely, Vibrated Concrete relies on proper on-site compaction, which can vary in quality, potentially leading to inconsistent durability performance.

Cost Implications of SCC vs Vibrated Concrete

Self-compacting concrete (SCC) typically has higher initial material costs due to specialized admixtures and mix design requirements compared to vibrated concrete, which uses traditional components and mechanical consolidation. However, SCC reduces labor expenses and equipment rental by eliminating the need for vibration, potentially lowering overall project costs in complex formworks or congested reinforcement scenarios. The cost-benefit balance often favors SCC in large-scale or intricate projects, while vibrated concrete remains more cost-effective for straightforward pours with accessible reinforcement layouts.

Sustainability and Environmental Impact

Self-compacting concrete (SCC) reduces environmental impact by minimizing the need for mechanical vibration, which decreases energy consumption and noise pollution on construction sites. SCC enhances sustainability through optimized mix designs that often incorporate supplementary cementitious materials like fly ash or slag, reducing cement content and associated CO2 emissions. In contrast, vibrated concrete requires additional energy for vibration, potentially increasing overall carbon footprint despite its widespread use for achieving compaction.

Ideal Applications for Self-Compacting and Vibrated Concrete

Self-compacting concrete (SCC) is ideal for complex formworks, densely reinforced structures, and areas with limited access where vibration is difficult or labor-intensive. Vibrated concrete is best suited for large-scale structural elements like foundations, columns, and slabs where compaction equipment can be effectively used to remove entrapped air and ensure density. SCC improves surface finish and reduces labor costs in intricate projects, while vibrated concrete offers reliability and strength in conventional applications.

Self-Compacting Concrete vs Vibrated Concrete Infographic

materialdif.com

materialdif.com