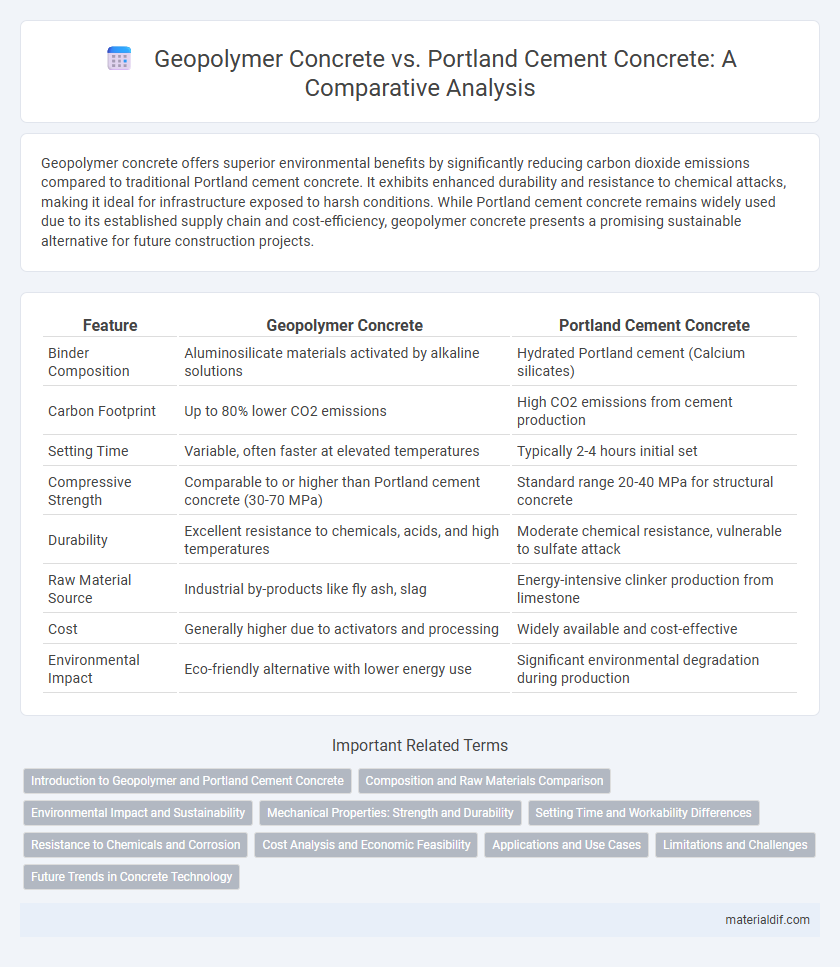

Geopolymer concrete offers superior environmental benefits by significantly reducing carbon dioxide emissions compared to traditional Portland cement concrete. It exhibits enhanced durability and resistance to chemical attacks, making it ideal for infrastructure exposed to harsh conditions. While Portland cement concrete remains widely used due to its established supply chain and cost-efficiency, geopolymer concrete presents a promising sustainable alternative for future construction projects.

Table of Comparison

| Feature | Geopolymer Concrete | Portland Cement Concrete |

|---|---|---|

| Binder Composition | Aluminosilicate materials activated by alkaline solutions | Hydrated Portland cement (Calcium silicates) |

| Carbon Footprint | Up to 80% lower CO2 emissions | High CO2 emissions from cement production |

| Setting Time | Variable, often faster at elevated temperatures | Typically 2-4 hours initial set |

| Compressive Strength | Comparable to or higher than Portland cement concrete (30-70 MPa) | Standard range 20-40 MPa for structural concrete |

| Durability | Excellent resistance to chemicals, acids, and high temperatures | Moderate chemical resistance, vulnerable to sulfate attack |

| Raw Material Source | Industrial by-products like fly ash, slag | Energy-intensive clinker production from limestone |

| Cost | Generally higher due to activators and processing | Widely available and cost-effective |

| Environmental Impact | Eco-friendly alternative with lower energy use | Significant environmental degradation during production |

Introduction to Geopolymer and Portland Cement Concrete

Geopolymer concrete is an innovative material that utilizes industrial by-products like fly ash and slag, activated by alkaline solutions to form a durable binder with reduced carbon emissions compared to traditional cement. Portland cement concrete, widely used globally, relies on the hydration of clinker minerals derived from limestone and clay, contributing significantly to global CO2 emissions due to energy-intensive production processes. Geopolymer concrete offers enhanced chemical resistance and thermal stability, positioning it as a sustainable alternative to conventional Portland cement concrete in construction applications.

Composition and Raw Materials Comparison

Geopolymer concrete primarily consists of aluminosilicate materials such as fly ash or slag, combined with alkaline activators like sodium hydroxide or sodium silicate, offering a sustainable alternative to traditional Portland cement. Portland cement concrete relies on clinker produced from limestone and clay, which is energy-intensive and emits higher CO2 levels during production. The use of industrial by-products in geopolymer concrete reduces environmental impact while providing comparable strength and durability to conventional Portland cement concrete.

Environmental Impact and Sustainability

Geopolymer concrete significantly reduces carbon dioxide emissions, producing up to 80% less CO2 compared to Portland cement concrete, due to its utilization of industrial by-products like fly ash and slag. Its sustainability profile is strengthened by lower energy consumption during production and enhanced durability, which reduces the need for frequent repairs and replacements. The reduction in raw material extraction and waste generation positions geopolymer concrete as an eco-friendly alternative fostering sustainable construction practices.

Mechanical Properties: Strength and Durability

Geopolymer concrete exhibits higher compressive strength and superior chemical resistance compared to Portland cement concrete, making it ideal for harsh environmental conditions. Its enhanced durability stems from its low permeability and resistance to sulfate and chloride attacks, extending structural lifespan. Portland cement concrete, while widely used, often experiences reduced durability due to carbonation and alkali-silica reactions that compromise mechanical integrity over time.

Setting Time and Workability Differences

Geopolymer concrete typically exhibits a longer setting time compared to Portland cement concrete due to its chemical composition, which relies on aluminosilicate materials activated by alkaline solutions. This extended setting time allows for improved workability, making geopolymer concrete easier to mold and place in complex forms without rapid stiffening. In contrast, Portland cement concrete sets faster but may require additives to enhance workability and prevent early hardening during construction.

Resistance to Chemicals and Corrosion

Geopolymer concrete exhibits superior resistance to chemicals and corrosion compared to Portland cement concrete due to its low calcium content and dense microstructure, which reduce alkali-silica reaction and sulfate attack. Its geopolymeric binder provides enhanced durability against acidic and saline environments, prolonging the structural lifespan in aggressive conditions. Portland cement concrete, however, is more susceptible to chloride-induced corrosion and chemical degradation, leading to reduced performance in harsh industrial or marine applications.

Cost Analysis and Economic Feasibility

Geopolymer concrete offers significant cost savings over Portland cement concrete due to its use of industrial by-products like fly ash and slag, which lower raw material expenses and reduce environmental remediation costs. The economic feasibility of geopolymer concrete is enhanced by lower energy consumption during production and increased durability, leading to reduced maintenance and lifecycle costs. Despite higher initial setup costs for alkali activators, overall financial analysis shows geopolymer concrete as a viable, cost-effective alternative in sustainable construction projects.

Applications and Use Cases

Geopolymer concrete excels in high-temperature resistance and chemical durability, making it ideal for industrial flooring, fire-resistant structures, and wastewater treatment plants. Portland cement concrete remains widely used for general construction purposes like pavements, bridges, and residential buildings due to its well-established performance and availability. The choice between the two depends on specific use cases requiring sustainability and aggressive environment resistance versus traditional strength and cost-efficiency.

Limitations and Challenges

Geopolymer concrete faces limitations such as variability in raw material composition, which affects consistency and long-term performance compared to Portland cement concrete. Challenges include the lack of standardized mix design protocols and limited field applications, leading to hesitancy among engineers and contractors. Additionally, sourcing industrial by-products like fly ash and slag for geopolymer production can be inconsistent, impacting large-scale implementation.

Future Trends in Concrete Technology

Geopolymer concrete exhibits enhanced durability, lower carbon emissions, and improved resistance to chemical attacks compared to traditional Portland cement concrete, making it a promising material for sustainable construction. Emerging trends emphasize the integration of nanomaterials and advanced curing techniques to optimize mechanical properties and accelerate strength development in geopolymer concrete. Increased research on waste-based aluminosilicate sources and scalable production methods is driving the transition toward eco-friendly, high-performance concrete solutions for future infrastructure.

Geopolymer Concrete vs Portland Cement Concrete Infographic

materialdif.com

materialdif.com