Pozzolanic concrete incorporates pozzolanic materials such as fly ash or volcanic ash, which react with calcium hydroxide to form additional cementitious compounds, enhancing strength and durability. Non-pozzolanic concrete relies solely on Portland cement hydration, resulting in lower resistance to chemical attack and reduced long-term performance. The use of pozzolanic materials improves resistance to sulfate attack, reduces permeability, and minimizes alkali-silica reaction, making it a superior choice for sustainable construction.

Table of Comparison

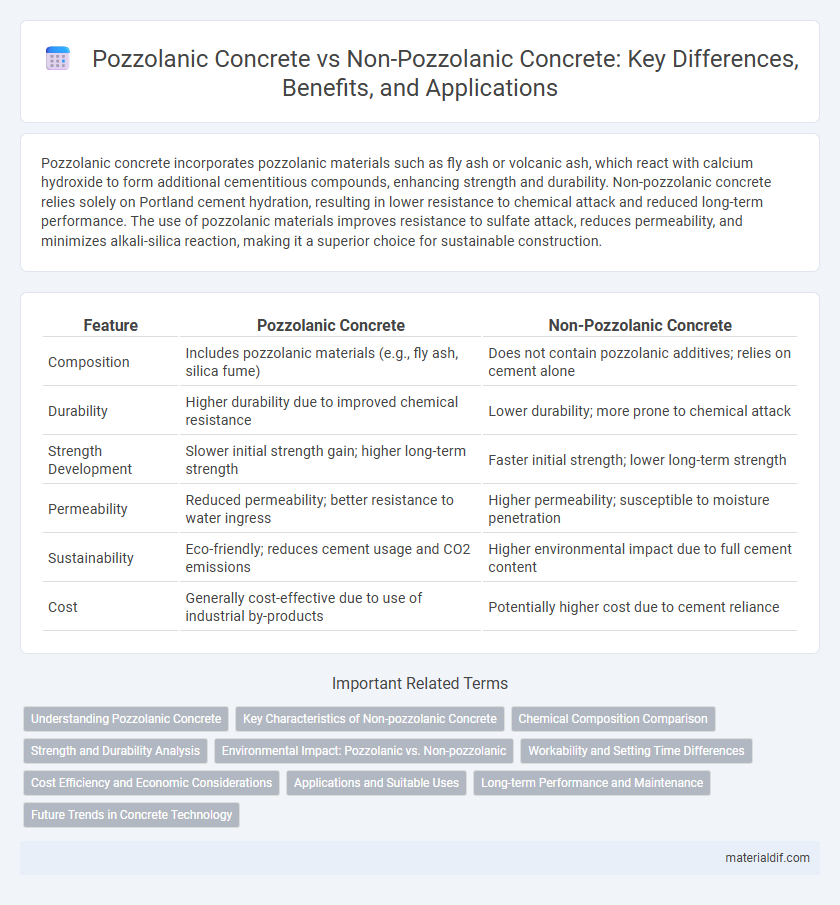

| Feature | Pozzolanic Concrete | Non-Pozzolanic Concrete |

|---|---|---|

| Composition | Includes pozzolanic materials (e.g., fly ash, silica fume) | Does not contain pozzolanic additives; relies on cement alone |

| Durability | Higher durability due to improved chemical resistance | Lower durability; more prone to chemical attack |

| Strength Development | Slower initial strength gain; higher long-term strength | Faster initial strength; lower long-term strength |

| Permeability | Reduced permeability; better resistance to water ingress | Higher permeability; susceptible to moisture penetration |

| Sustainability | Eco-friendly; reduces cement usage and CO2 emissions | Higher environmental impact due to full cement content |

| Cost | Generally cost-effective due to use of industrial by-products | Potentially higher cost due to cement reliance |

Understanding Pozzolanic Concrete

Pozzolanic concrete incorporates pozzolanic materials such as fly ash, silica fume, or volcanic ash, enhancing its durability and strength through a chemical reaction with calcium hydroxide. This reaction forms additional calcium silicate hydrate (C-S-H), which improves resistance to sulfate attack, reduces permeability, and increases long-term strength compared to non-pozzolanic concrete. Pozzolanic concrete also offers environmental benefits by reducing cement consumption and lowering carbon dioxide emissions during production.

Key Characteristics of Non-pozzolanic Concrete

Non-pozzolanic concrete primarily relies on Portland cement without the addition of supplementary cementitious materials such as fly ash, silica fume, or slag. It typically exhibits lower resistance to chemical attack and reduced durability in aggressive environments compared to pozzolanic concrete. This type of concrete also tends to have higher permeability and decreased long-term strength due to the absence of pozzolanic reactions that enhance the microstructure.

Chemical Composition Comparison

Pozzolanic concrete incorporates supplementary cementitious materials such as fly ash, silica fume, or volcanic ash, which contain reactive silica and alumina that chemically react with calcium hydroxide to form additional calcium silicate hydrate (C-S-H), enhancing durability and strength. Non-pozzolanic concrete primarily relies on Portland cement and lacks these reactive components, resulting in a chemical composition dominated by calcium silicates and limited secondary hydration products. The key difference in chemical composition lies in the presence of pozzolanic materials that consume free lime and contribute to a denser microstructure in pozzolanic concrete compared to the more porous matrix of non-pozzolanic concrete.

Strength and Durability Analysis

Pozzolanic concrete exhibits superior strength and enhanced durability compared to non-pozzolanic concrete due to the incorporation of pozzolanic materials such as fly ash, silica fume, or volcanic ash, which react chemically with calcium hydroxide to form additional calcium silicate hydrate (C-S-H). This secondary C-S-H gel significantly reduces porosity and improves resistance to chemical attacks, sulfate ingress, and chloride penetration, thereby increasing the lifespan of structures. Non-pozzolanic concrete typically has lower long-term strength development and higher permeability, making it more susceptible to environmental degradation and reduced durability in aggressive conditions.

Environmental Impact: Pozzolanic vs. Non-pozzolanic

Pozzolanic concrete significantly reduces carbon emissions by replacing a portion of Portland cement with industrial byproducts like fly ash or silica fume, leading to lower embodied CO2 compared to non-pozzolanic concrete. The enhanced durability and longer lifespan of pozzolanic concrete minimize resource consumption and waste generation over time. Non-pozzolanic concrete relies entirely on Portland cement, which is energy-intensive and responsible for approximately 7% of global CO2 emissions, resulting in higher environmental impact.

Workability and Setting Time Differences

Pozzolanic concrete incorporates pozzolanic materials like fly ash or silica fume, which enhance workability by improving the mix's cohesiveness and reducing water demand compared to non-pozzolanic concrete. The presence of pozzolans influences setting time, typically resulting in a slower initial set but improved long-term strength gain due to secondary hydration reactions. Non-pozzolanic concrete tends to have a faster setting time but may suffer from reduced workability and durability without the supplementary cementitious benefits of pozzolanic compounds.

Cost Efficiency and Economic Considerations

Pozzolanic concrete offers significant cost efficiency through the partial replacement of cement with pozzolanic materials such as fly ash or silica fume, which reduces overall material expenses and enhances durability, lowering long-term maintenance costs. Non-pozzolanic concrete typically incurs higher initial costs due to the exclusive use of Portland cement and may require more frequent repairs because of lower resistance to chemical attacks and cracking. Investing in pozzolanic concrete improves economic outcomes by extending the service life of structures and decreasing lifecycle costs compared to conventional non-pozzolanic mixtures.

Applications and Suitable Uses

Pozzolanic concrete, enriched with materials like fly ash or silica fume, enhances durability and resistance to chemical attacks, making it ideal for infrastructure exposed to harsh environments such as marine structures, sewage treatment plants, and bridges. Non-pozzolanic concrete suits general construction needs with faster setting times, commonly applied in residential buildings, pavements, and non-industrial floors. The choice between pozzolanic and non-pozzolanic concrete depends on environmental exposure, required longevity, and project-specific strength criteria.

Long-term Performance and Maintenance

Pozzolanic concrete exhibits superior long-term performance due to its enhanced durability, reduced permeability, and increased resistance to chemical attacks, resulting in lower maintenance requirements over time compared to non-pozzolanic concrete. The pozzolanic reaction contributes to the continual formation of additional calcium silicate hydrate (C-S-H), which improves strength and minimizes microcracking, extending the service life of structures. Non-pozzolanic concrete typically demands more frequent repairs and maintenance due to higher susceptibility to sulfate attack, alkali-silica reaction, and freeze-thaw cycles.

Future Trends in Concrete Technology

Pozzolanic concrete incorporates supplementary cementitious materials like fly ash or silica fume, enhancing durability, reducing permeability, and improving sustainability by lowering carbon emissions. Future trends emphasize the development of advanced pozzolanic blends with nanomaterials and bio-based additives to further optimize mechanical properties and environmental performance. Non-pozzolanic concrete faces increased scrutiny due to lower sustainability potential, driving research and industry adoption toward innovative pozzolanic formulations and eco-friendly cement alternatives.

Pozzolanic Concrete vs Non-pozzolanic Concrete Infographic

materialdif.com

materialdif.com