Fiber-reinforced concrete incorporates fibers such as steel, glass, or synthetic materials to enhance tensile strength and crack resistance, making it ideal for structural applications requiring improved durability. Polymer-modified concrete uses polymer additives to improve adhesion, flexibility, and water resistance, often employed in repair works and overlays where enhanced bonding and impermeability are critical. Both materials offer distinct advantages in extending the lifespan and performance of concrete structures under varying environmental and load conditions.

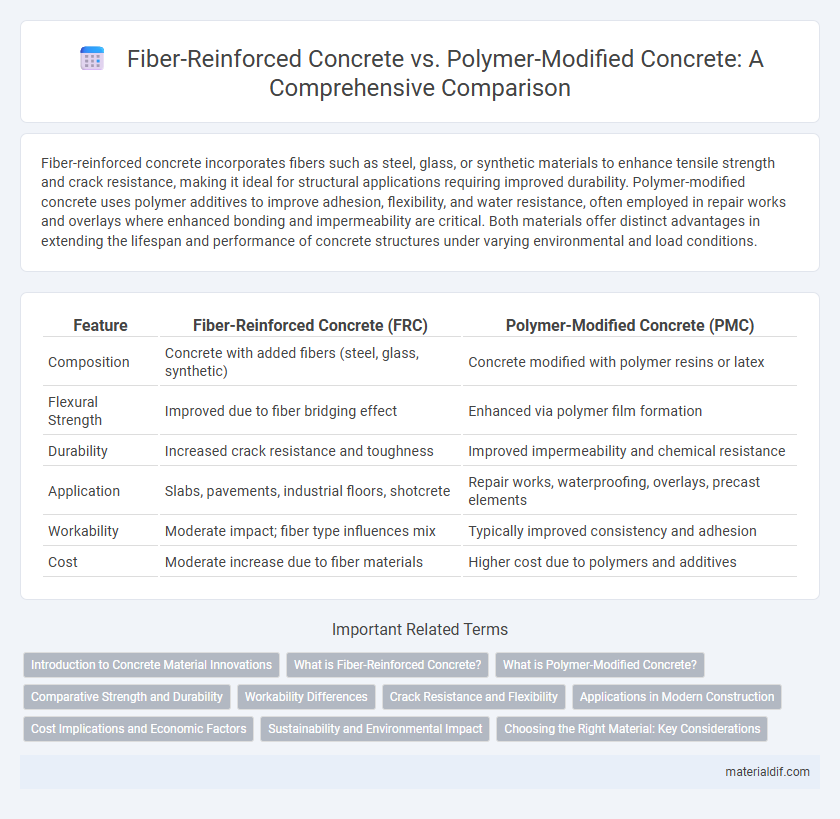

Table of Comparison

| Feature | Fiber-Reinforced Concrete (FRC) | Polymer-Modified Concrete (PMC) |

|---|---|---|

| Composition | Concrete with added fibers (steel, glass, synthetic) | Concrete modified with polymer resins or latex |

| Flexural Strength | Improved due to fiber bridging effect | Enhanced via polymer film formation |

| Durability | Increased crack resistance and toughness | Improved impermeability and chemical resistance |

| Application | Slabs, pavements, industrial floors, shotcrete | Repair works, waterproofing, overlays, precast elements |

| Workability | Moderate impact; fiber type influences mix | Typically improved consistency and adhesion |

| Cost | Moderate increase due to fiber materials | Higher cost due to polymers and additives |

Introduction to Concrete Material Innovations

Fiber-reinforced concrete enhances tensile strength and crack resistance by integrating fibers such as steel, glass, or synthetic polymers, crucial for structural durability and impact resistance. Polymer-modified concrete incorporates polymers like latex or acrylics to improve adhesion, flexibility, and chemical resistance, making it ideal for repair applications and harsh environments. Both innovations address conventional concrete's limitations by optimizing mechanical properties and longevity for modern infrastructure needs.

What is Fiber-Reinforced Concrete?

Fiber-reinforced concrete (FRC) is a composite material consisting of concrete embedded with discrete fibers such as steel, glass, synthetic, or natural fibers to improve its structural integrity and durability. These fibers enhance tensile strength, reduce cracking, and increase impact resistance by distributing stresses more evenly throughout the concrete matrix. FRC is widely used in pavements, industrial floors, and structural elements where enhanced mechanical properties and crack control are critical.

What is Polymer-Modified Concrete?

Polymer-modified concrete (PMC) is a type of concrete enhanced by the addition of polymer additives such as latex, redispersible powders, or redispersible polymer powders, which improve its adhesion, flexibility, and durability. These polymers enhance the concrete's resistance to chemical attack, reduce permeability, and improve bonding with reinforcement, making it ideal for repair works and overlays. Compared to fiber-reinforced concrete, PMC offers superior resistance to water penetration and better performance in aggressive environmental conditions.

Comparative Strength and Durability

Fiber-reinforced concrete incorporates synthetic or steel fibers that significantly enhance tensile strength and crack resistance, making it ideal for structural applications subjected to dynamic loads. Polymer-modified concrete integrates polymers that improve adhesion, flexibility, and impermeability, resulting in superior durability against chemical attacks and freeze-thaw cycles. Comparative studies indicate fiber-reinforced concrete excels in impact resistance and toughness, while polymer-modified concrete offers better long-term durability and resistance to environmental degradation.

Workability Differences

Fiber-reinforced concrete enhances structural integrity by incorporating fibers that improve toughness but can reduce workability due to fiber clumping and increased mix stiffness. Polymer-modified concrete improves workability by introducing polymers that increase bonding and flexibility, resulting in smoother placement and finishing. Workability differences arise as fiber-reinforced mixes often require more water or admixtures to maintain slump, whereas polymer modification naturally enhances flow without sacrificing strength.

Crack Resistance and Flexibility

Fiber-Reinforced Concrete (FRC) significantly enhances crack resistance through the distribution of microfibers, which bridge cracks and prevent their propagation, resulting in improved structural durability. Polymer-Modified Concrete (PMC) increases flexibility and reduces permeability by incorporating polymers that create a more cohesive and elastic matrix, allowing better resistance to deformation under stress. Both FRC and PMC improve crack resistance, but FRC excels in controlling crack width while PMC offers superior flexibility and adhesion to substrates.

Applications in Modern Construction

Fiber-reinforced concrete (FRC) enhances structural integrity and crack resistance, making it ideal for industrial floors, tunnel linings, and bridge decks where durability under heavy loads is critical. Polymer-modified concrete (PMC) improves adhesion, flexibility, and chemical resistance, suited for applications like repair mortars, overlays, and precast components exposed to harsh environmental conditions. Both materials play pivotal roles in modern construction by addressing specific performance requirements and extending the service life of infrastructure.

Cost Implications and Economic Factors

Fiber-reinforced concrete typically incurs higher initial material costs due to the incorporation of synthetic or steel fibers, but it can reduce long-term expenses by enhancing durability and lowering maintenance needs. Polymer-modified concrete often demands additional polymer additives that increase upfront costs, yet it improves adhesion and chemical resistance, potentially extending service life and reducing repair frequency. Economic factors favor fiber-reinforced concrete in applications requiring impact resistance and toughness, while polymer-modified concrete is cost-effective in situations demanding enhanced flexibility and waterproofing.

Sustainability and Environmental Impact

Fiber-reinforced concrete enhances durability and reduces crack propagation, leading to longer service life and less frequent repairs, which minimizes material consumption and environmental waste. Polymer-modified concrete offers improved resistance to chemicals and water ingress, extending structure lifespan but often involves synthetic polymers derived from non-renewable resources, raising concerns about environmental footprint. Sustainable construction favors fiber-reinforced concrete for its use of natural or recycled fibers, lower embodied energy, and potential for reduced carbon emissions throughout the concrete lifecycle.

Choosing the Right Material: Key Considerations

Fiber-reinforced concrete offers enhanced tensile strength and crack resistance by incorporating steel, glass, or synthetic fibers, making it ideal for structural applications requiring durability. Polymer-modified concrete improves adhesion, chemical resistance, and flexibility through polymer additives, suited for surfaces exposed to harsh environments or frequent wear. Selecting between these materials depends on specific project demands such as load-bearing capacity, environmental exposure, and desired longevity.

Fiber-Reinforced Concrete vs Polymer-Modified Concrete Infographic

materialdif.com

materialdif.com