Lightweight aggregate is produced from natural materials such as expanded shale, clay, or slate, resulting in concrete with lower density and improved thermal insulation compared to normal weight aggregate, which is typically composed of crushed stone or gravel. Concrete made with lightweight aggregate offers reduced dead load, enhanced fire resistance, and better sound absorption, making it ideal for high-rise buildings and bridge decks. However, normal weight aggregate concrete generally provides higher compressive strength and durability, suitable for heavy load-bearing structures and infrastructure projects.

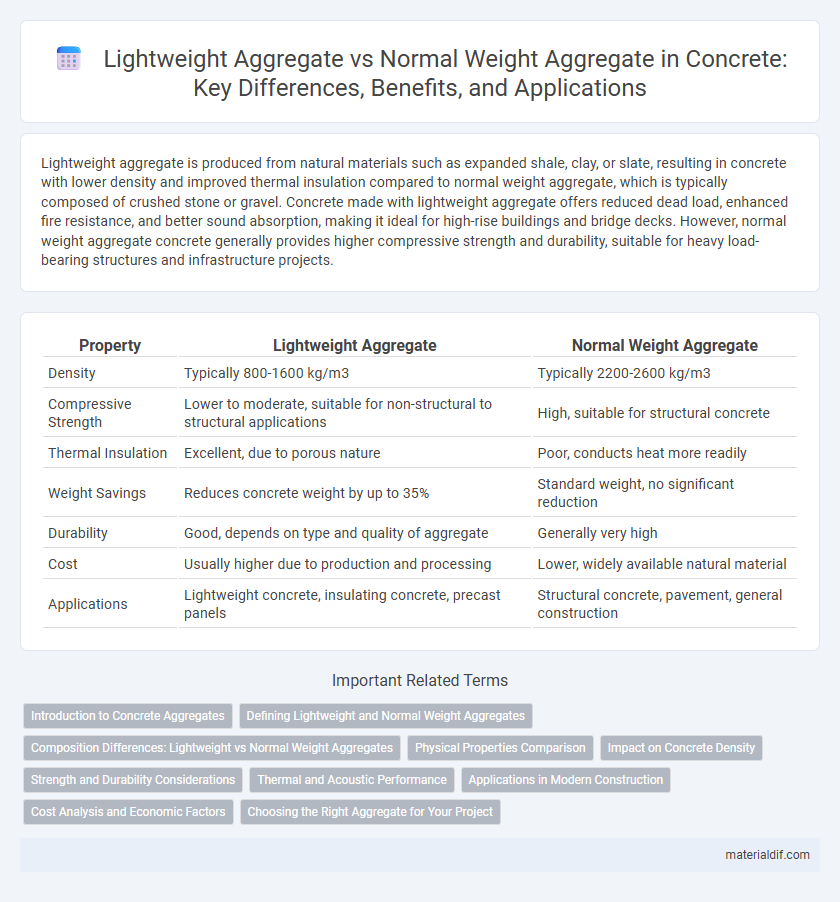

Table of Comparison

| Property | Lightweight Aggregate | Normal Weight Aggregate |

|---|---|---|

| Density | Typically 800-1600 kg/m3 | Typically 2200-2600 kg/m3 |

| Compressive Strength | Lower to moderate, suitable for non-structural to structural applications | High, suitable for structural concrete |

| Thermal Insulation | Excellent, due to porous nature | Poor, conducts heat more readily |

| Weight Savings | Reduces concrete weight by up to 35% | Standard weight, no significant reduction |

| Durability | Good, depends on type and quality of aggregate | Generally very high |

| Cost | Usually higher due to production and processing | Lower, widely available natural material |

| Applications | Lightweight concrete, insulating concrete, precast panels | Structural concrete, pavement, general construction |

Introduction to Concrete Aggregates

Lightweight aggregate, derived from expanded clay, shale, or slate, offers reduced density compared to normal weight aggregate such as gravel and crushed stone, making it ideal for applications requiring lower structural load and improved thermal insulation. Normal weight aggregate provides high compressive strength and durability, essential for heavy-duty structural concrete in infrastructure projects. Concrete aggregates significantly influence concrete properties including strength, weight, thermal conductivity, and durability, with the choice between lightweight and normal weight aggregates determined by project-specific performance criteria.

Defining Lightweight and Normal Weight Aggregates

Lightweight aggregates are porous materials such as expanded clay, shale, or slate, characterized by their low density, typically ranging from 300 to 1,200 kg/m3, which reduces the overall weight of concrete. Normal weight aggregates include natural sand, gravel, or crushed stone with densities between 1,600 and 2,000 kg/m3, providing standard strength and durability in concrete mixes. The fundamental distinction lies in the aggregate's density and porosity, impacting the concrete's thermal insulation properties, strength, and structural performance.

Composition Differences: Lightweight vs Normal Weight Aggregates

Lightweight aggregates are typically composed of expanded shale, clay, or slate, resulting in porous structures that reduce density and improve thermal insulation in concrete. Normal weight aggregates consist mainly of natural gravel, crushed stone, or sand with dense mineral compositions like quartz and feldspar, providing higher compressive strength and durability. The distinct mineral content and porosity of lightweight aggregates significantly affect the workability, density, and mechanical properties of the resulting concrete mix compared to normal weight aggregates.

Physical Properties Comparison

Lightweight aggregate typically exhibits a lower density ranging from 500 to 1,600 kg/m3 compared to normal weight aggregate, which ranges from 1,600 to 2,000 kg/m3, resulting in reduced structural load. Porosity in lightweight aggregates is significantly higher due to their vesicular or expanded cellular structure, enhancing thermal insulation but reducing compressive strength relative to normal weight aggregates. Absorption rates for lightweight aggregates can exceed 15%, whereas normal weight aggregates usually exhibit absorption below 5%, affecting water demand and workability in concrete mixtures.

Impact on Concrete Density

Lightweight aggregate reduces concrete density significantly, typically ranging from 1,400 to 1,850 kg/m3, compared to normal weight aggregate which averages around 2,400 kg/m3. This reduction in density improves thermal insulation and decreases structural load, making lightweight concrete ideal for high-rise buildings and bridge decks. Despite the lower density, lightweight aggregate concrete maintains adequate strength, balancing performance and weight efficiency.

Strength and Durability Considerations

Lightweight aggregate concrete typically exhibits lower compressive strength compared to normal weight aggregate concrete due to its porous structure; however, its strength is sufficient for many structural applications and can be enhanced with proper mix design. Durability of lightweight aggregate concrete is often superior in freeze-thaw resistance and thermal insulation but may require additional measures to prevent abrasion and impact damage. Normal weight aggregate concrete provides higher density and typically greater strength and abrasion resistance, making it preferable for heavy load-bearing and high-wear environments.

Thermal and Acoustic Performance

Lightweight aggregate concrete offers superior thermal insulation due to its lower density and higher porosity, reducing heat transfer compared to normal weight aggregate concrete. It also enhances acoustic performance by absorbing sound waves more effectively, resulting in better noise reduction in buildings. Normal weight aggregate concrete, while structurally robust, typically provides less thermal efficiency and sound attenuation.

Applications in Modern Construction

Lightweight aggregate is extensively used in modern construction to reduce structural load, improve thermal insulation, and enhance fire resistance, making it ideal for high-rise buildings and precast panels. Normal weight aggregate, with its higher density and compressive strength, remains preferred for foundations, pavements, and heavy-duty structures requiring durability and resistance to wear. The selection between lightweight and normal weight aggregate depends on the specific performance requirements, balancing weight savings with structural integrity in contemporary construction projects.

Cost Analysis and Economic Factors

Lightweight aggregate concrete typically incurs higher initial costs due to specialized materials like expanded clay or shale, but offers long-term economic benefits through reduced structural load and lower transportation expenses. Normal weight aggregate, derived from natural gravel or crushed stone, generally has lower upfront costs but can increase total expenses due to heavier weight affecting foundation design and labor. Cost analysis must consider lifecycle factors such as energy efficiency, labor savings, and potential reductions in foundation size when comparing lightweight and normal weight aggregates in concrete applications.

Choosing the Right Aggregate for Your Project

Lightweight aggregate offers benefits such as reduced dead load and improved insulation, making it ideal for high-rise buildings and precast panels, whereas normal weight aggregate provides higher compressive strength and better durability for heavy-duty structural applications. Selection depends on project requirements including load-bearing capacity, thermal properties, and cost considerations. Understanding specific performance criteria ensures optimal aggregate choice, enhancing concrete strength, weight, and overall efficiency.

Lightweight aggregate vs normal weight aggregate Infographic

materialdif.com

materialdif.com