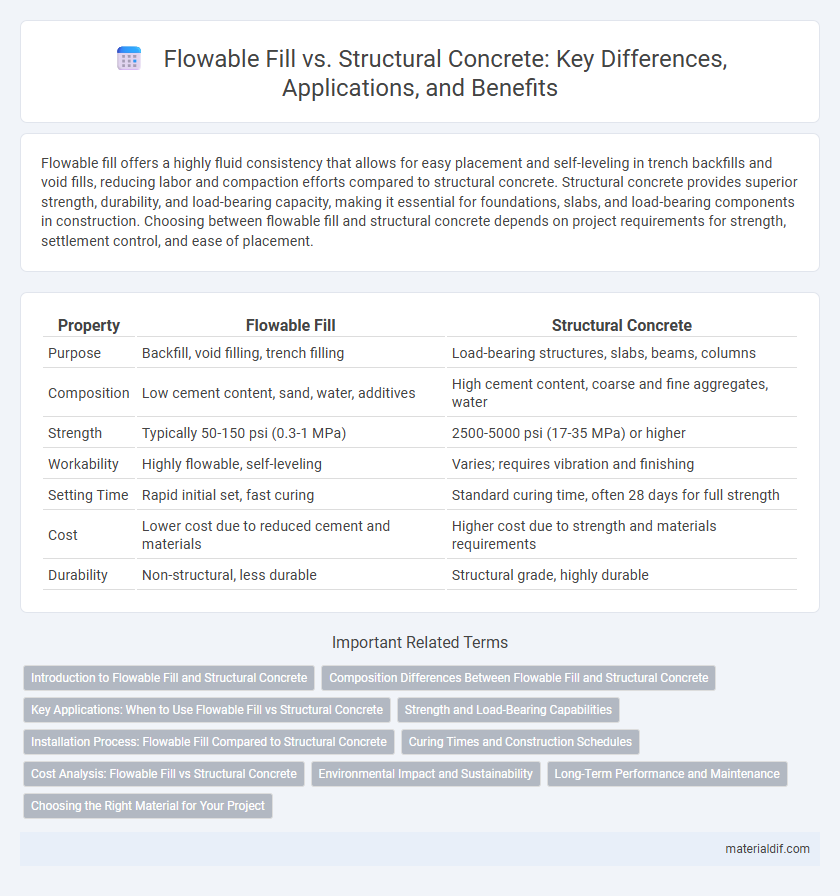

Flowable fill offers a highly fluid consistency that allows for easy placement and self-leveling in trench backfills and void fills, reducing labor and compaction efforts compared to structural concrete. Structural concrete provides superior strength, durability, and load-bearing capacity, making it essential for foundations, slabs, and load-bearing components in construction. Choosing between flowable fill and structural concrete depends on project requirements for strength, settlement control, and ease of placement.

Table of Comparison

| Property | Flowable Fill | Structural Concrete |

|---|---|---|

| Purpose | Backfill, void filling, trench filling | Load-bearing structures, slabs, beams, columns |

| Composition | Low cement content, sand, water, additives | High cement content, coarse and fine aggregates, water |

| Strength | Typically 50-150 psi (0.3-1 MPa) | 2500-5000 psi (17-35 MPa) or higher |

| Workability | Highly flowable, self-leveling | Varies; requires vibration and finishing |

| Setting Time | Rapid initial set, fast curing | Standard curing time, often 28 days for full strength |

| Cost | Lower cost due to reduced cement and materials | Higher cost due to strength and materials requirements |

| Durability | Non-structural, less durable | Structural grade, highly durable |

Introduction to Flowable Fill and Structural Concrete

Flowable fill, also known as controlled low-strength material (CLSM), is a self-compacting, cementitious material used primarily for soil stabilization, trench backfill, and utility bedding, offering high flowability and easy placement without mechanical compaction. Structural concrete, composed of cement, aggregates, water, and admixtures, is designed to withstand significant loads and provide strength and durability for buildings, bridges, and infrastructure. The key difference lies in flowable fill's lower strength and higher fluidity suited for non-structural applications, while structural concrete is engineered for load-bearing performance.

Composition Differences Between Flowable Fill and Structural Concrete

Flowable fill is primarily composed of fine aggregates, water, and a low cement content, often augmented with fly ash or slag to enhance fluidity and reduce strength, making it suitable for non-structural applications like backfilling. Structural concrete contains a higher cement content, coarse aggregates, water, and admixtures designed to achieve high compressive strength and durability for load-bearing construction. The key compositional difference lies in aggregate size and cement paste ratio, influencing flowability and mechanical properties.

Key Applications: When to Use Flowable Fill vs Structural Concrete

Flowable fill is ideal for utility trenches, void filling, and non-load-bearing applications due to its self-leveling and easy placement properties. Structural concrete is essential for load-bearing elements like foundations, columns, and beams requiring high strength and durability. Selecting between flowable fill and structural concrete depends on load requirements, with flowable fill preferred for non-structural support and structural concrete for critical strength performance.

Strength and Load-Bearing Capabilities

Flowable fill exhibits lower compressive strength, typically ranging from 100 to 1,200 psi, making it unsuitable for load-bearing applications where structural concrete is essential. Structural concrete is engineered with high compressive strength values, often exceeding 3,000 psi, providing superior load-bearing capacity for foundations, columns, and beams. The difference in mix design and aggregate composition directly influences their strength, with structural concrete offering resilience and durability critical for permanent structural elements.

Installation Process: Flowable Fill Compared to Structural Concrete

Flowable fill offers a simpler and faster installation process compared to structural concrete, requiring minimal labor and specialized equipment due to its self-leveling and pumpable consistency. Structural concrete demands extensive formwork, reinforcement placement, and precise curing techniques to achieve required strength and durability. The efficient placement of flowable fill reduces site downtime and labor costs, making it ideal for non-structural applications such as backfill and trench fills.

Curing Times and Construction Schedules

Flowable fill offers significantly faster curing times compared to structural concrete, often reaching sufficient strength within 24 hours, which accelerates construction schedules and reduces project downtime. Structural concrete typically requires curing periods ranging from 7 to 28 days to achieve optimal strength, necessitating longer wait times before load application or subsequent construction activities. Utilizing flowable fill in non-structural applications can streamline timelines and improve overall site efficiency without compromising stability in backfill and trench repair projects.

Cost Analysis: Flowable Fill vs Structural Concrete

Flowable fill offers significant cost savings compared to structural concrete due to lower material expenses and reduced labor requirements, especially in non-structural applications. Its self-leveling properties minimize equipment rental costs and speed up installation times, further lowering overall project expenses. However, structural concrete remains more cost-effective for load-bearing uses where strength and durability are critical, despite higher initial costs.

Environmental Impact and Sustainability

Flowable fill, a self-compacting, low-strength material, offers significant environmental benefits compared to structural concrete due to its lower cement content and reduced carbon footprint. Structural concrete, typically high in Portland cement, contributes substantially to CO2 emissions during production, whereas flowable fill's use of industrial byproducts like fly ash enhances sustainability by recycling waste materials. The lightweight nature and reduced material demand of flowable fill lessen energy consumption in transportation and installation, promoting greener construction practices.

Long-Term Performance and Maintenance

Flowable fill, also known as controlled low-strength material (CLSM), provides excellent long-term stability with minimal maintenance due to its self-compacting and low-permeability properties, reducing the risk of settlement and infiltration. Structural concrete offers superior load-bearing capacity and durability for long-term infrastructure performance but requires regular inspection and maintenance to address potential cracking and corrosion of reinforcement. Selecting between flowable fill and structural concrete depends on the specific application requirements, balancing initial placement ease with anticipated structural demands and maintenance needs.

Choosing the Right Material for Your Project

Flowable fill offers high workability and rapid placement for non-structural applications like backfilling and void filling, providing easier installation and reduced labor costs. Structural concrete delivers superior strength and durability essential for load-bearing elements such as foundations, columns, and slabs, ensuring long-term stability and compliance with building codes. Selecting between flowable fill and structural concrete depends on load requirements, project specifications, and intended use to optimize performance and cost-efficiency.

Flowable Fill vs Structural Concrete Infographic

materialdif.com

materialdif.com