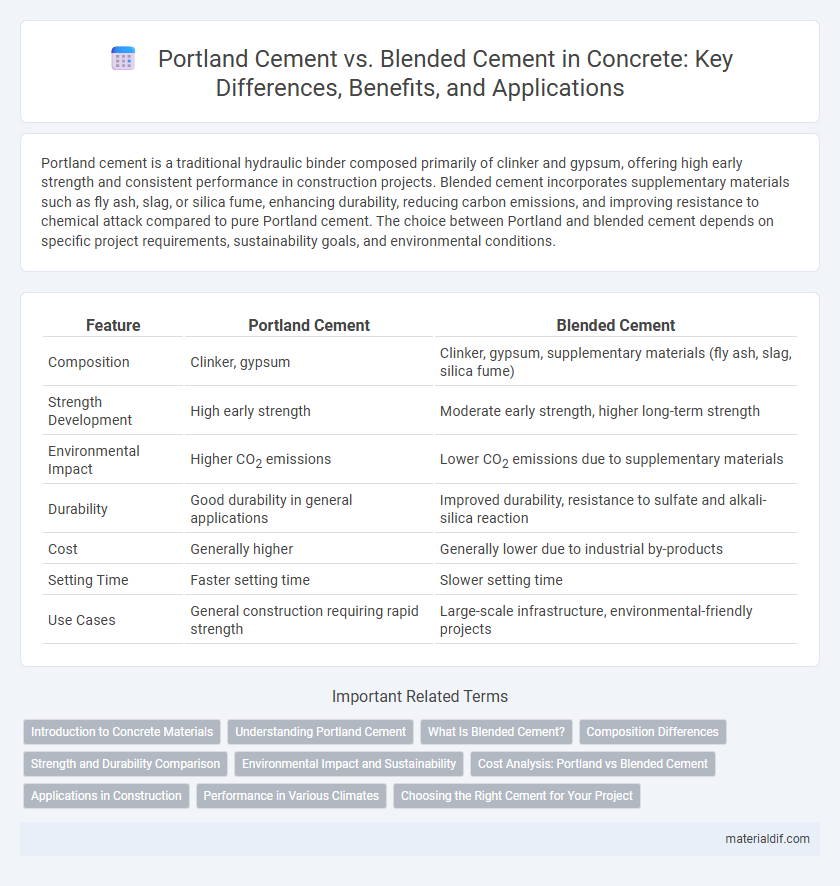

Portland cement is a traditional hydraulic binder composed primarily of clinker and gypsum, offering high early strength and consistent performance in construction projects. Blended cement incorporates supplementary materials such as fly ash, slag, or silica fume, enhancing durability, reducing carbon emissions, and improving resistance to chemical attack compared to pure Portland cement. The choice between Portland and blended cement depends on specific project requirements, sustainability goals, and environmental conditions.

Table of Comparison

| Feature | Portland Cement | Blended Cement |

|---|---|---|

| Composition | Clinker, gypsum | Clinker, gypsum, supplementary materials (fly ash, slag, silica fume) |

| Strength Development | High early strength | Moderate early strength, higher long-term strength |

| Environmental Impact | Higher CO2 emissions | Lower CO2 emissions due to supplementary materials |

| Durability | Good durability in general applications | Improved durability, resistance to sulfate and alkali-silica reaction |

| Cost | Generally higher | Generally lower due to industrial by-products |

| Setting Time | Faster setting time | Slower setting time |

| Use Cases | General construction requiring rapid strength | Large-scale infrastructure, environmental-friendly projects |

Introduction to Concrete Materials

Portland cement, composed primarily of clinker and gypsum, serves as the fundamental binding ingredient in concrete, providing high early strength and durability. Blended cement combines Portland cement with supplementary materials like fly ash, slag, or silica fume to enhance workability, reduce heat of hydration, and improve long-term durability. Choosing between Portland and blended cement can significantly influence concrete performance, sustainability, and cost efficiency in construction projects.

Understanding Portland Cement

Portland cement is a hydraulic binder made primarily from clinker, consisting of calcium silicates, aluminates, and ferrites, essential for concrete's structural strength and durability. It hydrates and hardens when mixed with water, forming a dense matrix that binds aggregates together. Understanding its composition and curing properties is vital for optimizing concrete performance in construction projects.

What Is Blended Cement?

Blended cement is a mixture of Portland cement clinker and supplementary cementitious materials (SCMs) such as fly ash, slag, or silica fume, designed to improve durability and sustainability. It reduces carbon emissions by replacing a portion of the clinker, which is the most energy-intensive component in cement production. Blended cements enhance workability, reduce permeability, and increase resistance to chemical attacks compared to pure Portland cement.

Composition Differences

Portland cement primarily consists of clinker, composed of calcium silicates, aluminates, and ferrites, with a small percentage of gypsum to control setting time. Blended cement combines Portland cement clinker with supplementary cementitious materials such as fly ash, slag, or silica fume, which enhance durability and reduce environmental impact. The varied composition in blended cement improves chemical resistance and reduces the heat of hydration compared to traditional Portland cement.

Strength and Durability Comparison

Portland cement offers high early strength and consistent durability, making it ideal for structural applications requiring quick load-bearing capacity. Blended cement, incorporating supplementary materials like fly ash or slag, enhances long-term durability by improving resistance to chemical attacks and reducing permeability, though it may develop strength more slowly. The choice depends on project-specific requirements for immediate strength versus prolonged durability and environmental performance.

Environmental Impact and Sustainability

Portland cement production accounts for approximately 8% of global CO2 emissions due to the energy-intensive calcination process and fossil fuel use. Blended cement incorporates supplementary materials like fly ash, slag, or natural pozzolans, significantly reducing carbon footprint by lowering clinker content. This substitution enhances sustainability by conserving natural resources and improving durability, thus extending the lifespan of concrete structures and reducing lifecycle environmental impact.

Cost Analysis: Portland vs Blended Cement

Portland cement generally incurs higher production costs due to its energy-intensive manufacturing process and reliance on pure raw materials, making it more expensive than blended cement. Blended cement incorporates supplementary materials like fly ash, slag, or silica fume, which lowers the overall cost by reducing clinker content and utilizing industrial by-products. Cost savings with blended cement become more significant in large-scale construction projects due to improved material efficiency and reduced carbon footprint benefits.

Applications in Construction

Portland cement is widely used in structural concrete applications such as bridges, buildings, and pavements due to its high early strength and durability. Blended cement, which incorporates supplementary materials like fly ash or slag, enhances workability and reduces heat of hydration, making it ideal for large-scale projects and sustainable construction. Both types optimize concrete performance, but blended cement is preferred for eco-friendly and long-term durability projects.

Performance in Various Climates

Portland cement shows excellent strength development and durability in moderate climates but may suffer from shrinkage and cracking in extreme temperature variations. Blended cement, containing supplementary materials like fly ash or slag, offers enhanced resistance to chemical attacks and improved performance in both hot and cold environments by reducing permeability and thermal cracking. In humid or marine climates, blended cement significantly reduces chloride penetration, extending the lifespan of concrete structures.

Choosing the Right Cement for Your Project

Portland cement offers high early strength and durability, making it ideal for structural concrete in buildings and infrastructure projects. Blended cement, which incorporates supplementary materials like fly ash or slag, improves workability, reduces heat generation, and enhances long-term durability, suitable for large-scale projects requiring sustainability and cost-efficiency. Selecting the right cement depends on factors such as project specifications, environmental conditions, and desired performance characteristics to ensure optimal concrete strength and longevity.

Portland Cement vs Blended Cement Infographic

materialdif.com

materialdif.com