Lightweight aggregate offers improved insulation and reduced structural load compared to normal aggregate, making it ideal for high-rise buildings and thermal applications. Normal aggregate provides higher compressive strength and better durability, suitable for heavy-duty construction projects. The choice between these aggregates depends on the balance between weight reduction and strength requirements.

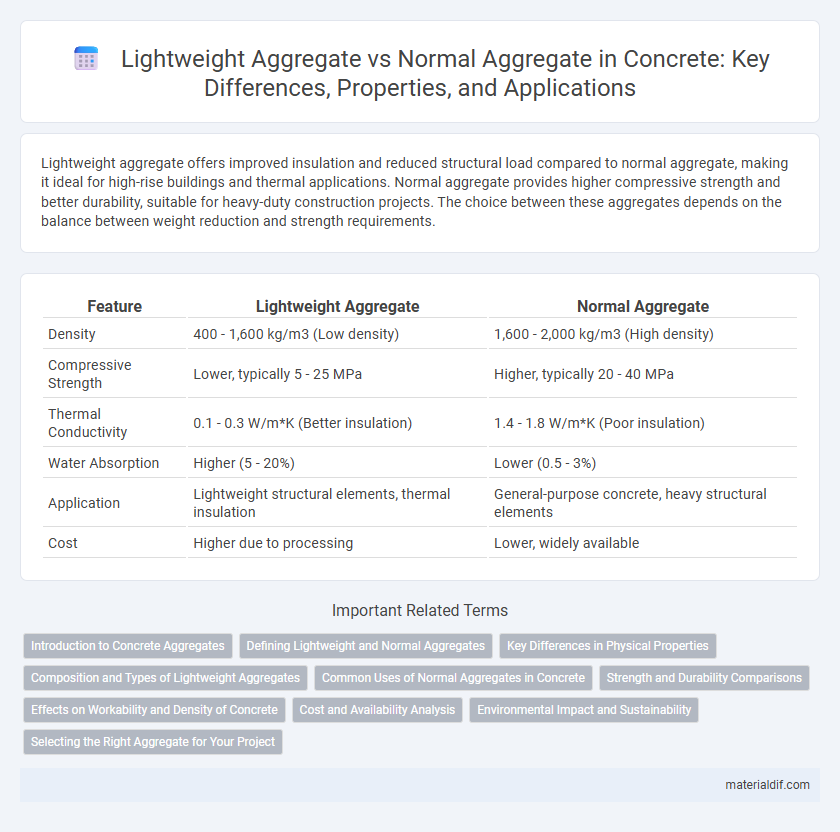

Table of Comparison

| Feature | Lightweight Aggregate | Normal Aggregate |

|---|---|---|

| Density | 400 - 1,600 kg/m3 (Low density) | 1,600 - 2,000 kg/m3 (High density) |

| Compressive Strength | Lower, typically 5 - 25 MPa | Higher, typically 20 - 40 MPa |

| Thermal Conductivity | 0.1 - 0.3 W/m*K (Better insulation) | 1.4 - 1.8 W/m*K (Poor insulation) |

| Water Absorption | Higher (5 - 20%) | Lower (0.5 - 3%) |

| Application | Lightweight structural elements, thermal insulation | General-purpose concrete, heavy structural elements |

| Cost | Higher due to processing | Lower, widely available |

Introduction to Concrete Aggregates

Lightweight aggregates, derived from expanded shale, clay, or slate, offer reduced density and enhanced thermal insulation compared to normal aggregates, which are primarily natural gravel or crushed stone. The choice between lightweight and normal aggregates significantly influences concrete's strength, durability, and weight, impacting structural performance and cost efficiency. Understanding the physical and mechanical properties of these aggregates is essential for optimizing concrete mix design in construction projects.

Defining Lightweight and Normal Aggregates

Lightweight aggregate consists of materials such as expanded shale, clay, or slate, characterized by lower density and high porosity, reducing the overall weight of concrete. Normal aggregate typically comprises natural sand, gravel, or crushed stone with higher density and lower porosity, providing greater compressive strength. The choice between lightweight and normal aggregates significantly influences concrete's thermal insulation, structural load, and durability properties.

Key Differences in Physical Properties

Lightweight aggregate exhibits lower density, typically ranging from 400 to 1,800 kg/m3, compared to normal aggregate which usually falls between 2,400 and 2,900 kg/m3, significantly reducing the overall weight of concrete. Porosity in lightweight aggregates is higher, enhancing thermal insulation and reducing thermal conductivity, while normal aggregates have lower porosity and higher strength. The absorption capacity of lightweight aggregates is substantially greater, leading to increased water demand in concrete mix design relative to the relatively impermeable normal aggregates.

Composition and Types of Lightweight Aggregates

Lightweight aggregates consist primarily of expanded clay, shale, slate, or pumice, which are thermally processed to reduce density and improve thermal insulation properties compared to normal aggregates like gravel and crushed stone. Their porous structure results from the expansion of gases during manufacturing, yielding a lower unit weight and enhanced fire resistance. Common types of lightweight aggregates include expanded clay aggregate (ECA), expanded shale, and volcanic pumice, each contributing to reduced dead load and improved workability in concrete applications.

Common Uses of Normal Aggregates in Concrete

Normal aggregates, commonly composed of natural materials such as gravel, sand, and crushed stone, are widely used in concrete for structural applications including foundations, slabs, beams, and columns due to their high density and strength. These aggregates provide essential durability and load-bearing capacity necessary for infrastructure projects like highways, bridges, and buildings. Their prevalence in construction stems from their cost-effectiveness and proven performance in conventional concrete mixes requiring high compressive strength.

Strength and Durability Comparisons

Lightweight aggregate concrete typically exhibits lower compressive strength than normal aggregate concrete due to the porous nature of aggregates like expanded clay or shale, which reduces density but can impact load-bearing capacity. However, advanced lightweight aggregates engineered for higher strength provide improved durability by enhancing resistance to freeze-thaw cycles, chemical attacks, and reducing creep and shrinkage. Normal aggregate concrete often delivers superior structural strength but may be more susceptible to cracking and deterioration under aggressive environmental conditions, impacting long-term performance.

Effects on Workability and Density of Concrete

Lightweight aggregates reduce the density of concrete by incorporating porous materials such as expanded clay or shale, resulting in a material with improved thermal insulation and reduced dead load, yet lower compressive strength compared to normal aggregates. The porous nature of lightweight aggregates increases water absorption, which can decrease workability and require adjustments in mix design or additional water-reducing admixtures to maintain consistency. Normal aggregates, typically denser and non-porous, provide higher workability and compressive strength, but increase overall concrete weight, affecting structural load considerations.

Cost and Availability Analysis

Lightweight aggregates such as expanded clay, shale, and slate typically incur higher initial costs compared to normal aggregates like crushed stone or gravel, due to specialized production processes. However, lightweight aggregates often result in reduced transportation expenses and lower structural loads, which can decrease overall project costs. Availability of normal aggregates is generally more widespread, making them more accessible and affordable in many regions, whereas lightweight aggregates may be limited to specific geographic areas with suitable raw materials and production facilities.

Environmental Impact and Sustainability

Lightweight aggregates, often derived from industrial by-products like fly ash or expanded shale, significantly reduce environmental impact by lowering transportation emissions due to their reduced weight and enhancing energy efficiency in concrete structures through improved thermal insulation. Normal aggregates, typically sourced from natural riverbeds or quarries, contribute to habitat destruction, resource depletion, and higher carbon footprints associated with extraction and processing. Using lightweight aggregates promotes sustainability by minimizing raw material consumption and supporting circular economy principles in the construction industry.

Selecting the Right Aggregate for Your Project

Lightweight aggregate offers advantages such as reduced structural load and improved thermal insulation, making it ideal for high-rise buildings and precast elements, while normal aggregate provides higher compressive strength suitable for heavy-duty construction like bridges and foundations. Consider factors like project load requirements, durability, and cost efficiency when selecting between lightweight and normal aggregates to optimize both performance and budget. Evaluating the specific mechanical properties, such as density and strength, ensures the aggregate choice aligns with your project's structural and environmental demands.

Lightweight Aggregate vs Normal Aggregate Infographic

materialdif.com

materialdif.com