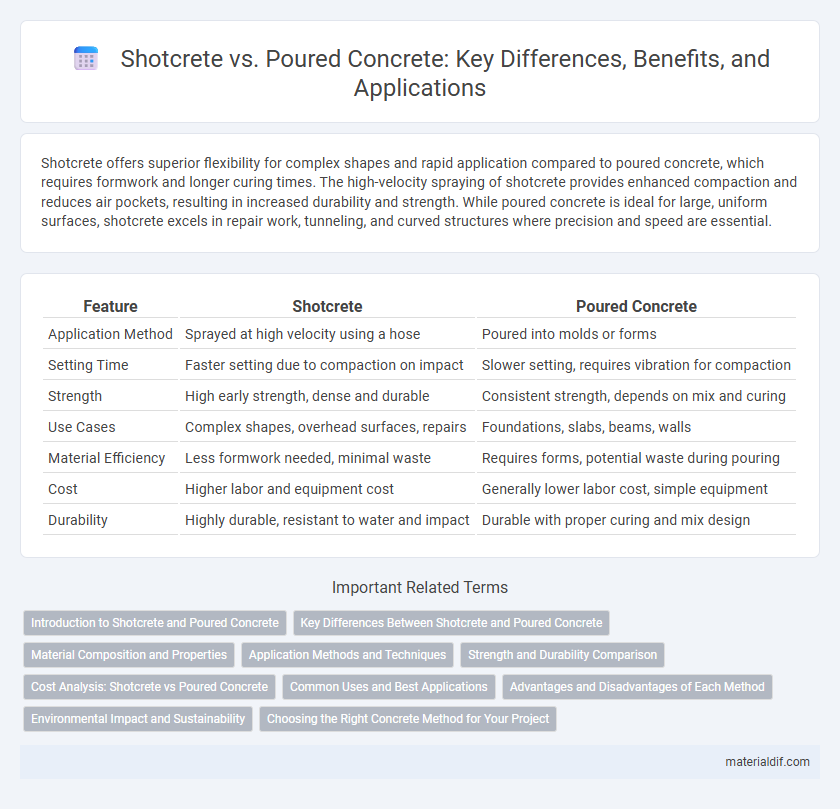

Shotcrete offers superior flexibility for complex shapes and rapid application compared to poured concrete, which requires formwork and longer curing times. The high-velocity spraying of shotcrete provides enhanced compaction and reduces air pockets, resulting in increased durability and strength. While poured concrete is ideal for large, uniform surfaces, shotcrete excels in repair work, tunneling, and curved structures where precision and speed are essential.

Table of Comparison

| Feature | Shotcrete | Poured Concrete |

|---|---|---|

| Application Method | Sprayed at high velocity using a hose | Poured into molds or forms |

| Setting Time | Faster setting due to compaction on impact | Slower setting, requires vibration for compaction |

| Strength | High early strength, dense and durable | Consistent strength, depends on mix and curing |

| Use Cases | Complex shapes, overhead surfaces, repairs | Foundations, slabs, beams, walls |

| Material Efficiency | Less formwork needed, minimal waste | Requires forms, potential waste during pouring |

| Cost | Higher labor and equipment cost | Generally lower labor cost, simple equipment |

| Durability | Highly durable, resistant to water and impact | Durable with proper curing and mix design |

Introduction to Shotcrete and Poured Concrete

Shotcrete, a method of applying concrete through a high-pressure hose, offers rapid placement and superior adhesion, ideal for complex shapes and overhead applications. Poured concrete involves placing fluid concrete into formwork, allowing for precise molding and uniform structural strength in foundations and slabs. Both methods utilize cement, aggregates, and water but differ significantly in application techniques and suitable construction scenarios.

Key Differences Between Shotcrete and Poured Concrete

Shotcrete is applied pneumatically at high velocity, allowing for better adhesion and reduced formwork, while poured concrete is placed by gravity into fixed molds. Shotcrete offers superior compaction and is ideal for complex shapes or repairs, whereas poured concrete provides uniform density and is suited for large, flat surfaces. The curing process and water content also differ, with shotcrete requiring careful control to prevent rebound and ensure structural strength.

Material Composition and Properties

Shotcrete consists of a dry or wet mix of cement, sand, coarse aggregates, and water, often compressed through a high-velocity hose, resulting in superior compaction and adherence. Poured concrete combines cement, water, fine and coarse aggregates in a fluid mix, designed for casting in forms to achieve specific shapes and finishes. Shotcrete offers higher durability and resistance to cracking due to its dense, pneumatic placement, while poured concrete provides flexibility in structural applications with varying slump levels and reinforcement methods.

Application Methods and Techniques

Shotcrete involves pneumatically projecting concrete at high velocity onto surfaces, allowing for rapid application on irregular or vertical structures with minimal formwork. Poured concrete requires traditional formwork and gravity-based placement, making it ideal for horizontal slabs and foundations but less adaptable to complex shapes. Shotcrete's ability to adhere instantly enables efficient repair work and construction in confined spaces where poured concrete is impractical.

Strength and Durability Comparison

Shotcrete exhibits superior strength due to its dense, compacted application that enhances bond and reduces voids, making it ideal for structural repairs and complex shapes. Poured concrete offers consistent durability and high compressive strength, benefiting from controlled curing and uniform composition, suitable for foundations and large-scale projects. Both materials provide excellent durability, but shotcrete's high adhesion and faster setting time give it an edge in environments requiring rapid strength gain and abrasion resistance.

Cost Analysis: Shotcrete vs Poured Concrete

Shotcrete generally incurs higher initial costs due to specialized equipment and skilled labor requirements, while poured concrete benefits from more standardized, cost-effective installation processes. However, shotcrete can reduce overall expenses by minimizing formwork and enabling faster application on complex surfaces. Long-term maintenance costs are typically lower for shotcrete because of its superior adhesion and durability in challenging environments.

Common Uses and Best Applications

Shotcrete is ideal for complex or curved surfaces such as swimming pools, tunnels, and retaining walls due to its ability to be sprayed onto vertical or overhead structures without formwork. Poured concrete excels in flat, horizontal slabs like floors, driveways, and sidewalks where uniform thickness and smooth finishes are required. Both materials offer high strength and durability, but shotcrete provides greater versatility for intricate or hard-to-reach areas while poured concrete is preferred for large, level surfaces.

Advantages and Disadvantages of Each Method

Shotcrete offers rapid application and excellent adhesion on irregular surfaces, making it ideal for complex shapes and overhead work, while its high cost and equipment requirements can limit use. Poured concrete provides uniform strength, easier quality control, and lower material costs, but requires formwork and longer curing times, which can delay project schedules. Both methods vary in suitability depending on structural needs and environmental conditions.

Environmental Impact and Sustainability

Shotcrete reduces environmental impact by minimizing waste and energy consumption compared to poured concrete due to its efficient application process and reduced formwork requirements. The ability to apply shotcrete in thin layers lowers material usage and transportation emissions, contributing to sustainability. Poured concrete, while durable, generates more waste and requires extensive formwork, increasing its carbon footprint relative to shotcrete.

Choosing the Right Concrete Method for Your Project

Shotcrete offers superior adhesion and faster application, making it ideal for complex shapes, overhead work, and repairs, while poured concrete provides greater structural strength and uniformity for larger, flat surfaces like slabs and foundations. The choice depends on project requirements such as surface geometry, load-bearing capacity, and application speed. Consider factors like site accessibility, labor costs, and desired finish quality when selecting between shotcrete and poured concrete methods.

Shotcrete vs poured concrete Infographic

materialdif.com

materialdif.com