White cement offers a brighter, more aesthetically appealing finish for decorative concrete projects, while gray cement provides superior strength and durability for structural applications. The choice between white and gray cement depends on the desired appearance and functional requirements of the pet concrete installation. White cement is ideal for intricate designs or colored overlays, whereas gray cement is best suited for foundational and load-bearing uses.

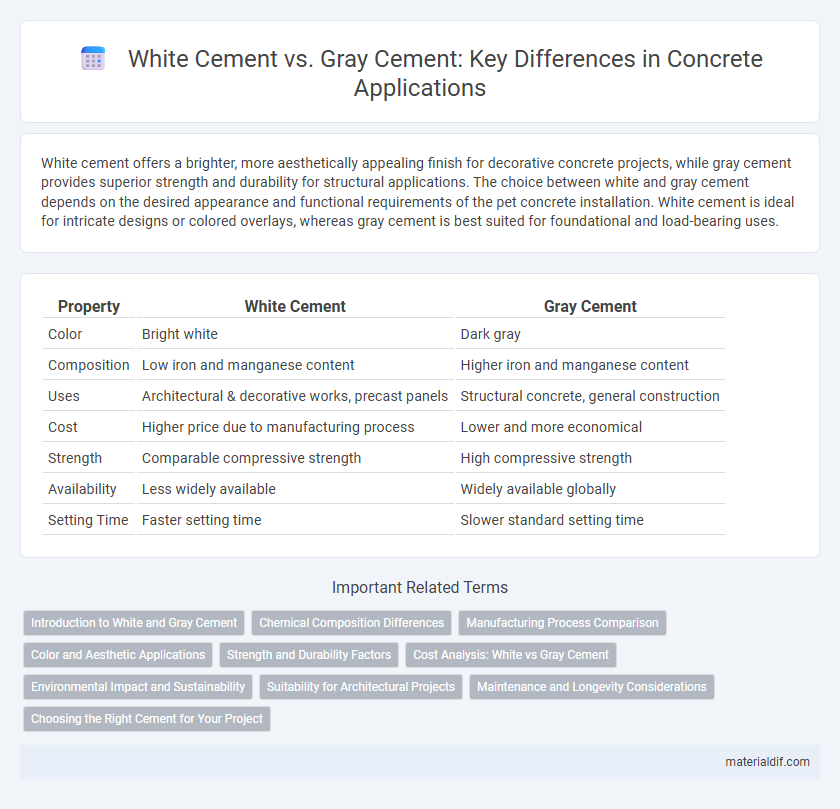

Table of Comparison

| Property | White Cement | Gray Cement |

|---|---|---|

| Color | Bright white | Dark gray |

| Composition | Low iron and manganese content | Higher iron and manganese content |

| Uses | Architectural & decorative works, precast panels | Structural concrete, general construction |

| Cost | Higher price due to manufacturing process | Lower and more economical |

| Strength | Comparable compressive strength | High compressive strength |

| Availability | Less widely available | Widely available globally |

| Setting Time | Faster setting time | Slower standard setting time |

Introduction to White and Gray Cement

White cement is a type of ordinary Portland cement characterized by its lighter color due to the absence of iron and manganese oxides, commonly used for architectural and decorative purposes. Gray cement, the most common form of Portland cement, contains higher amounts of iron and manganese, giving it its typical gray hue and making it suitable for general construction applications. Both types share similar chemical compositions but differ primarily in their color and aesthetic application.

Chemical Composition Differences

White cement contains lower amounts of iron oxide (Fe2O3) and manganese oxide (MnO), resulting in its characteristic light color, whereas gray cement has higher concentrations of these oxides that contribute to its darker hue. The chemical composition of white cement typically features less than 0.1% iron oxide, while gray cement can contain between 4-6% iron oxide. Both types primarily consist of calcium silicates, but the precise ratios and impurities influence properties such as color, setting time, and heat of hydration.

Manufacturing Process Comparison

White cement production involves the use of raw materials with low iron and manganese content to prevent discoloration, undergoing careful kiln firing at lower temperatures compared to gray cement. The manufacturing process includes the selection of pure kaolin, high-purity limestone, and low-iron bauxite, followed by rapid cooling to maintain a white color, contrasting with the higher iron content and longer cooling times in gray cement production. This controlled process results in the distinctive bright white color and finer particle size that differentiate white cement from traditional gray cement.

Color and Aesthetic Applications

White cement offers a distinct aesthetic advantage over gray cement due to its pure white color, making it ideal for decorative concrete, terrazzo flooring, and precast architectural elements. Its bright hue enhances the vibrancy of pigments, allowing for a wider range of color customization in design projects. Gray cement, with its natural gray tone, is commonly used for structural purposes where color is less critical, offering a classic and neutral base for various construction applications.

Strength and Durability Factors

White cement offers higher strength and superior durability compared to gray cement due to its refined raw materials and controlled manufacturing processes, resulting in fewer impurities and a denser microstructure. The enhanced compressive strength and resistance to chemical attacks make white cement ideal for architectural applications requiring both aesthetic appeal and long-term performance. In contrast, gray cement typically exhibits slightly lower strength and durability, making it suitable for general construction but less effective in aggressive environments.

Cost Analysis: White vs Gray Cement

White cement typically costs 20% to 30% more than gray cement due to its manufacturing process, which requires raw materials with low iron content and higher-grade clays. The increased price of white cement influences project budgets, especially in decorative applications where aesthetics are crucial. Despite higher costs, white cement offers added value through enhanced durability and visual appeal, often justifying the premium compared to the more economical gray cement.

Environmental Impact and Sustainability

White cement typically requires more energy and raw materials such as kaolin and bauxite, contributing to a higher carbon footprint compared to gray cement. Gray cement production utilizes more abundant and less processed materials like limestone and clay, resulting in relatively lower CO2 emissions and improved sustainability. Innovations in gray cement manufacturing, including the use of alternative fuels and clinker substitutes, further enhance its environmental performance over white cement.

Suitability for Architectural Projects

White cement offers superior aesthetic appeal and is ideal for architectural projects requiring bright, uniform color and smooth finishes, commonly used in decorative elements, facades, and precast panels. Gray cement, while more widely used and cost-effective, lacks the pure whiteness needed for visually striking designs and is better suited for structural purposes where color is less critical. Selecting white cement enhances visual impact and design flexibility in architectural applications, ensuring high-quality surface appearance and durability.

Maintenance and Longevity Considerations

White cement offers superior resistance to stains and weathering, making it ideal for maintenance-sensitive applications requiring a clean aesthetic. Gray cement, while more prone to discoloration over time, provides robust structural integrity and cost-effective durability in standard construction projects. Both cements benefit from proper curing and sealing techniques to enhance longevity and reduce maintenance frequency.

Choosing the Right Cement for Your Project

White cement offers superior aesthetic appeal and is ideal for decorative or architectural concrete projects requiring a bright, clean finish, while gray cement is preferred for structural applications due to its strength and cost-effectiveness. Selecting the right cement involves evaluating factors like color preference, exposure conditions, and project budget to ensure optimal performance and durability. Understanding the specific requirements of your concrete project ensures the appropriate choice between white and gray cement for both functionality and appearance.

White Cement vs Gray Cement Infographic

materialdif.com

materialdif.com