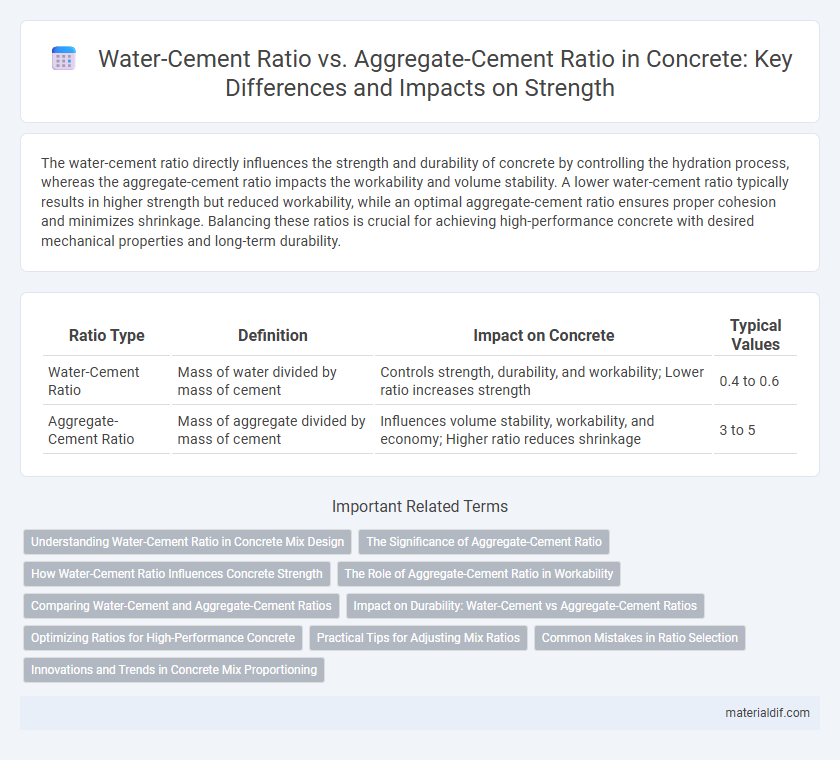

The water-cement ratio directly influences the strength and durability of concrete by controlling the hydration process, whereas the aggregate-cement ratio impacts the workability and volume stability. A lower water-cement ratio typically results in higher strength but reduced workability, while an optimal aggregate-cement ratio ensures proper cohesion and minimizes shrinkage. Balancing these ratios is crucial for achieving high-performance concrete with desired mechanical properties and long-term durability.

Table of Comparison

| Ratio Type | Definition | Impact on Concrete | Typical Values |

|---|---|---|---|

| Water-Cement Ratio | Mass of water divided by mass of cement | Controls strength, durability, and workability; Lower ratio increases strength | 0.4 to 0.6 |

| Aggregate-Cement Ratio | Mass of aggregate divided by mass of cement | Influences volume stability, workability, and economy; Higher ratio reduces shrinkage | 3 to 5 |

Understanding Water-Cement Ratio in Concrete Mix Design

The water-cement ratio in concrete mix design is a critical factor influencing strength, durability, and workability by controlling the hydration process of cement. A lower water-cement ratio enhances compressive strength and reduces permeability, while maintaining adequate aggregate-cement ratio ensures proper binder distribution and structural integrity. Precise adjustment of these ratios optimizes concrete performance for specific construction applications.

The Significance of Aggregate-Cement Ratio

Aggregate-cement ratio critically influences concrete's durability and strength by determining the volume of aggregates relative to cement paste, affecting workability and density. A balanced aggregate-cement ratio minimizes voids, reduces the risk of shrinkage, and enhances resistance to cracking and environmental degradation. Optimizing this ratio ensures efficient cement usage while maintaining structural integrity and cost-effectiveness in concrete mix design.

How Water-Cement Ratio Influences Concrete Strength

Water-cement ratio significantly impacts concrete strength by controlling the hydration process and pore structure formation within the hardened mix. Lower water-cement ratios yield higher strength due to reduced porosity, while higher ratios increase permeability and decrease durability. Optimal balance between water-cement and aggregate-cement ratios ensures workability without compromising structural integrity.

The Role of Aggregate-Cement Ratio in Workability

The aggregate-cement ratio plays a crucial role in determining the workability of concrete by influencing its consistency and ease of placement. A higher aggregate-cement ratio typically leads to reduced workability due to increased internal friction between particles, requiring more water or admixtures to achieve the desired flow. Optimizing the aggregate-cement ratio balances strength and workability, ensuring durable concrete with sufficient plasticity for construction processes.

Comparing Water-Cement and Aggregate-Cement Ratios

The water-cement ratio critically influences concrete strength and durability, with lower ratios enhancing compressive strength by reducing porosity. In contrast, the aggregate-cement ratio primarily affects workability and volume stability, where higher ratios improve dimensional stability but may reduce strength if excessive. Optimizing both ratios is essential for achieving balanced concrete performance, ensuring structural integrity and long-term durability.

Impact on Durability: Water-Cement vs Aggregate-Cement Ratios

The water-cement ratio significantly influences concrete durability by controlling porosity and permeability, where lower ratios enhance strength and reduce water ingress. In contrast, the aggregate-cement ratio mainly affects the concrete's dimensional stability and resistance to shrinkage, indirectly impacting durability through crack prevention. Optimal balance between these ratios ensures minimized microcracking and improved long-term resistance to environmental degradation.

Optimizing Ratios for High-Performance Concrete

Optimizing the water-cement ratio enhances concrete strength by minimizing excess water, while the aggregate-cement ratio influences durability and workability through proper aggregate sizing and grading. A low water-cement ratio below 0.40 typically achieves higher compressive strength, whereas maintaining an aggregate-cement ratio around 4 to 6 balances volume stability and reduces shrinkage. Precise control of these ratios in high-performance concrete results in improved mechanical properties, reduced porosity, and enhanced long-term durability.

Practical Tips for Adjusting Mix Ratios

Adjusting the water-cement ratio directly influences the concrete's strength and durability, with lower ratios increasing compressive strength but reducing workability. Balancing the aggregate-cement ratio ensures proper volume stability and minimizes shrinkage while maintaining adequate cohesiveness in the mix. Practical tips include incrementally modifying water content based on slump tests and adjusting aggregate proportions to optimize density without compromising mix consistency.

Common Mistakes in Ratio Selection

Common mistakes in selecting water-cement and aggregate-cement ratios include using excessive water that weakens concrete strength and improper aggregate proportions that reduce durability and workability. Overestimating the water-cement ratio often leads to higher porosity and decreased compressive strength. Incorrect aggregate-cement ratios can cause segregation or insufficient bonding, negatively impacting overall structural integrity.

Innovations and Trends in Concrete Mix Proportioning

Innovations in concrete mix proportioning emphasize optimizing the water-cement ratio to enhance hydration efficiency and durability while reducing permeability. Emerging trends focus on balancing the aggregate-cement ratio to improve workability and mechanical strength through advanced mineral admixtures and recycled aggregates. Digital tools and machine learning algorithms are increasingly utilized to precisely tailor mix proportions, minimizing water content without compromising aggregate integration, thus promoting sustainable and high-performance concrete formulations.

Water-Cement Ratio vs Aggregate-Cement Ratio Infographic

materialdif.com

materialdif.com