Rapid-set concrete offers significantly faster curing times compared to regular-set concrete, allowing for quicker project completion and early load bearing. Its formulation includes accelerators that enable strength development within hours, making it ideal for urgent repairs and time-sensitive applications. Regular-set concrete, while slower to cure, provides long-term durability and strength suited for standard construction timelines where extended workability is essential.

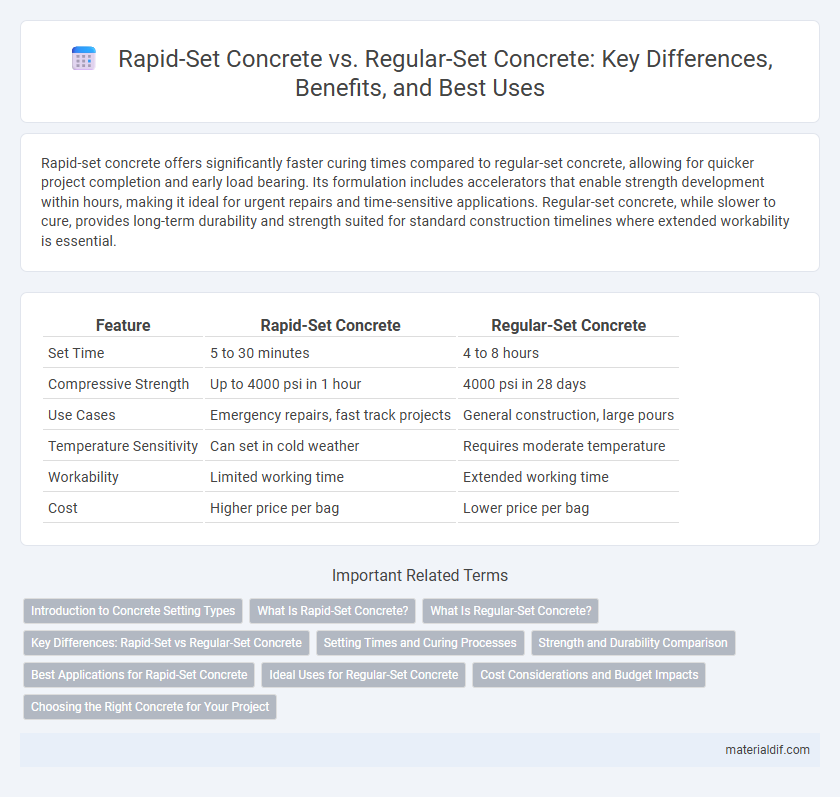

Table of Comparison

| Feature | Rapid-Set Concrete | Regular-Set Concrete |

|---|---|---|

| Set Time | 5 to 30 minutes | 4 to 8 hours |

| Compressive Strength | Up to 4000 psi in 1 hour | 4000 psi in 28 days |

| Use Cases | Emergency repairs, fast track projects | General construction, large pours |

| Temperature Sensitivity | Can set in cold weather | Requires moderate temperature |

| Workability | Limited working time | Extended working time |

| Cost | Higher price per bag | Lower price per bag |

Introduction to Concrete Setting Types

Rapid-set concrete cures within minutes to a few hours, enabling faster construction and early load-bearing capacity, ideal for emergency repairs and cold weather conditions. Regular-set concrete typically takes 24 to 48 hours to achieve initial set and up to 28 days for full strength development, providing extended workability for complex projects. Understanding setting times helps engineers select appropriate concrete types based on project timelines and environmental factors.

What Is Rapid-Set Concrete?

Rapid-set concrete is a specially formulated mixture designed to achieve high early strength and accelerated curing times, typically setting within 15 to 30 minutes. It contains fast-acting cementitious materials and chemical accelerators that allow for quick hardening, making it ideal for emergency repairs and time-sensitive projects. Unlike regular-set concrete, which takes several hours to set and days to fully cure, rapid-set concrete enables faster project turnaround and early load-bearing capacity.

What Is Regular-Set Concrete?

Regular-set concrete is a traditional concrete mix that typically sets within 24 to 48 hours, allowing ample time for handling and finishing before hardening. It consists of Portland cement, water, aggregates, and sometimes additives to enhance workability and durability. This type of concrete is widely used in standard construction projects where extended setting time is acceptable and precise placement is necessary.

Key Differences: Rapid-Set vs Regular-Set Concrete

Rapid-set concrete achieves initial set within 15 to 30 minutes, making it ideal for emergency repairs and fast-paced construction projects, while regular-set concrete typically sets in 4 to 6 hours, suitable for standard building applications. Rapid-set concrete contains accelerators like calcium chloride or proprietary additives to speed hydration, whereas regular-set concrete relies on natural curing processes. Strength development in rapid-set concrete reaches 3,000 psi within 1 to 3 hours, compared to 2,500 psi in 28 days for regular-set, highlighting its efficiency in time-sensitive environments.

Setting Times and Curing Processes

Rapid-set concrete achieves initial set within 15 to 30 minutes and reaches full strength in 24 hours, ideal for time-sensitive projects and emergency repairs. Regular-set concrete typically sets in 4 to 6 hours and requires 28 days to cure for maximum durability, making it suitable for standard construction applications. The accelerated curing process of rapid-set concrete reduces downtime but may require controlled mixing and placement to avoid compromised long-term strength.

Strength and Durability Comparison

Rapid-set concrete achieves high early strength within hours, often reaching compressive strengths above 3,000 psi in under 24 hours, making it ideal for time-sensitive projects. Regular-set concrete typically gains strength more gradually, reaching similar compressive strengths over 28 days, which contributes to long-term durability. Despite its faster curing time, rapid-set concrete maintains comparable resistance to cracking, weathering, and chemical exposure, ensuring reliable durability in demanding environments.

Best Applications for Rapid-Set Concrete

Rapid-set concrete is ideal for emergency repairs, fast-track construction projects, and cold weather applications due to its accelerated curing time, often reaching set within 15 to 60 minutes. This type of concrete is commonly used in road patching, utility repairs, and anchoring where downtime must be minimized to maintain safety and functionality. Its high early strength and resistance to freeze-thaw cycles make rapid-set concrete the preferred choice for time-sensitive and durable infrastructure maintenance tasks.

Ideal Uses for Regular-Set Concrete

Regular-set concrete is ideal for large-scale construction projects requiring extended workability time, such as highways, bridges, and residential foundations. Its slower curing process allows for thorough mixing, placement, and finishing, which is crucial in complex structures. This type of concrete is preferred when extended setting time is necessary to accommodate weather conditions or intricate formwork.

Cost Considerations and Budget Impacts

Rapid-set concrete typically incurs higher upfront costs compared to regular-set concrete due to specialized additives and faster curing technology. Budget impacts include potential savings in labor and project downtime, as rapid-set concrete allows for quicker form removal and earlier load application. Choosing between these options involves weighing initial material expenses against overall project timeline efficiency and associated labor costs.

Choosing the Right Concrete for Your Project

Rapid-set concrete cures within 15 to 60 minutes, making it ideal for urgent repairs and time-sensitive projects requiring early strength gain. Regular-set concrete typically sets in 24 to 48 hours, offering longer workability and better long-term durability for large-scale construction. Selecting the right concrete depends on project timeline, environmental conditions, and load-bearing requirements to ensure optimal performance and longevity.

Rapid-Set Concrete vs Regular-Set Concrete Infographic

materialdif.com

materialdif.com