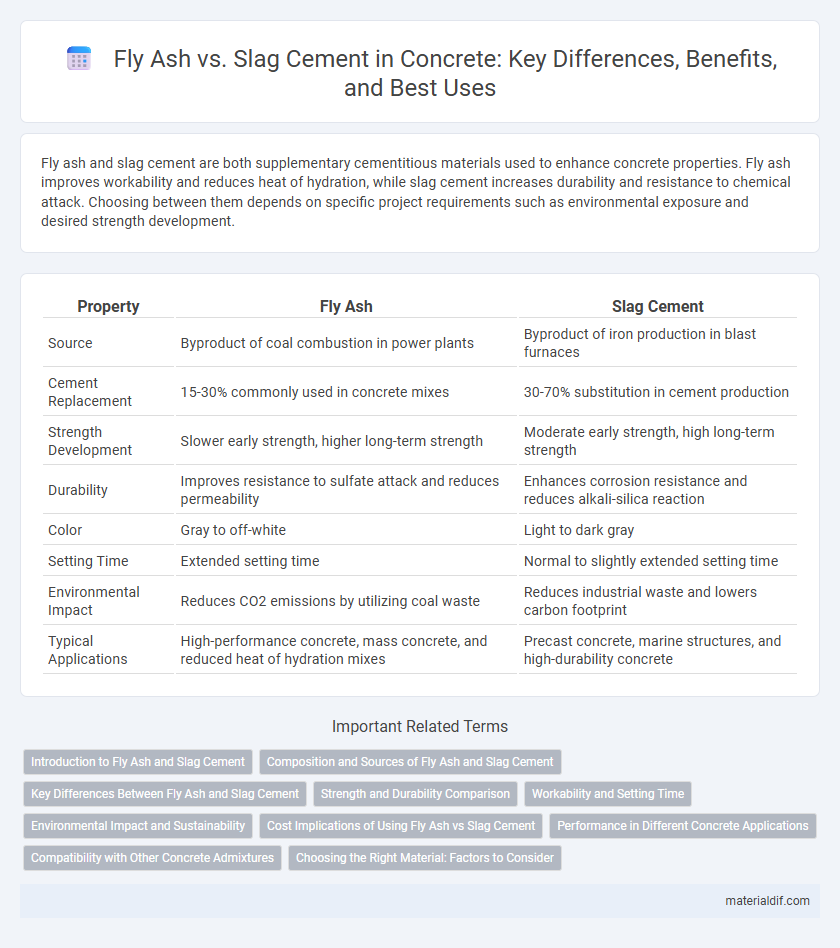

Fly ash and slag cement are both supplementary cementitious materials used to enhance concrete properties. Fly ash improves workability and reduces heat of hydration, while slag cement increases durability and resistance to chemical attack. Choosing between them depends on specific project requirements such as environmental exposure and desired strength development.

Table of Comparison

| Property | Fly Ash | Slag Cement |

|---|---|---|

| Source | Byproduct of coal combustion in power plants | Byproduct of iron production in blast furnaces |

| Cement Replacement | 15-30% commonly used in concrete mixes | 30-70% substitution in cement production |

| Strength Development | Slower early strength, higher long-term strength | Moderate early strength, high long-term strength |

| Durability | Improves resistance to sulfate attack and reduces permeability | Enhances corrosion resistance and reduces alkali-silica reaction |

| Color | Gray to off-white | Light to dark gray |

| Setting Time | Extended setting time | Normal to slightly extended setting time |

| Environmental Impact | Reduces CO2 emissions by utilizing coal waste | Reduces industrial waste and lowers carbon footprint |

| Typical Applications | High-performance concrete, mass concrete, and reduced heat of hydration mixes | Precast concrete, marine structures, and high-durability concrete |

Introduction to Fly Ash and Slag Cement

Fly ash is a fine, powdery material produced as a byproduct of coal combustion in power plants, widely used as a supplementary cementitious material (SCM) in concrete to enhance durability and reduce permeability. Slag cement, also known as ground granulated blast-furnace slag (GGBFS), is derived from the rapid cooling of molten iron slag from steel production, offering improved strength and resistance to chemical attack when blended with Portland cement. Both fly ash and slag cement contribute to sustainable concrete construction by recycling industrial byproducts and lowering CO2 emissions associated with traditional cement manufacturing.

Composition and Sources of Fly Ash and Slag Cement

Fly ash is a byproduct of coal combustion consisting mainly of silica, alumina, and iron oxide, sourced from pulverized coal-fired power plants. Slag cement, also known as ground granulated blast furnace slag (GGBFS), is derived from the molten slag of iron production in blast furnaces, primarily composed of calcium, silica, alumina, and magnesia. Both materials are used as supplementary cementitious materials to enhance concrete durability and sustainability.

Key Differences Between Fly Ash and Slag Cement

Fly ash, a byproduct of coal combustion, primarily consists of fine particles rich in silica and alumina, enhancing concrete durability and workability, while slag cement is derived from granulated blast furnace slag, offering higher early strength and improved sulfate resistance. Fly ash typically reduces heat of hydration and improves long-term strength gain, whereas slag cement accelerates setting time and provides excellent resistance to chemical attacks. The choice between fly ash and slag cement depends on specific project requirements such as environmental conditions, strength development timeline, and sustainability goals.

Strength and Durability Comparison

Fly ash and slag cement both enhance concrete strength and durability, with slag cement typically providing higher early strength gains due to its latent hydraulic properties. Fly ash improves long-term strength by refining the pore structure and reducing permeability, which enhances resistance to sulfate attack and alkali-silica reaction. Slag cement contributes to superior durability in aggressive environments by increasing resistance to chloride penetration and corrosion, making it ideal for marine and industrial applications.

Workability and Setting Time

Fly ash enhances concrete workability by improving its flow and reducing water demand, resulting in smoother placement and finishing. Slag cement also improves workability but tends to produce slightly slower setting times compared to fly ash, which accelerates the setting process moderately. Both materials contribute to improved durability but selecting between them depends on desired setting time and specific project requirements.

Environmental Impact and Sustainability

Fly ash, a byproduct of coal combustion, significantly reduces carbon emissions when used as a partial replacement for Portland cement, lowering the environmental footprint of concrete. Slag cement, derived from iron blast furnace slag, enhances durability and reduces the need for clinker production, contributing to sustainable construction. Both materials improve resource efficiency by recycling industrial waste, promoting circular economy principles in the concrete industry.

Cost Implications of Using Fly Ash vs Slag Cement

Fly ash generally offers a lower cost alternative to slag cement due to its widespread availability as a byproduct of coal combustion. Slag cement, derived from blast furnace slag, tends to be pricier because of limited supply and higher processing expenses. Incorporating fly ash can reduce overall concrete production costs while slag cement may provide enhanced durability benefits that justify its higher price in specific infrastructure projects.

Performance in Different Concrete Applications

Fly ash enhances concrete durability by improving workability and reducing permeability, making it ideal for mass concrete and high-performance applications. Slag cement contributes to higher early and ultimate strength, better resistance to chemical attack, and superior sulfate resistance, suitable for structural concrete in aggressive environments. Both materials improve sustainability but are selected based on specific performance requirements such as strength development rate and exposure conditions.

Compatibility with Other Concrete Admixtures

Fly ash exhibits high compatibility with most concrete admixtures, including superplasticizers, air-entraining agents, and accelerators, enhancing workability and durability. Slag cement also shows excellent synergy with chemical admixtures, promoting improved setting times and reduced permeability. Both materials contribute to optimized concrete performance when correctly integrated with admixture systems.

Choosing the Right Material: Factors to Consider

Selecting between fly ash and slag cement depends on project-specific factors such as desired strength, setting time, and durability requirements. Fly ash enhances workability and reduces heat of hydration, making it suitable for large-scale pours and mass concrete, while slag cement offers improved resistance to sulfate attack and chloride intrusion, ideal for harsh environments. Cost, availability, and environmental impact also influence the choice, with both materials contributing to sustainability by repurposing industrial byproducts.

Fly Ash vs Slag Cement Infographic

materialdif.com

materialdif.com