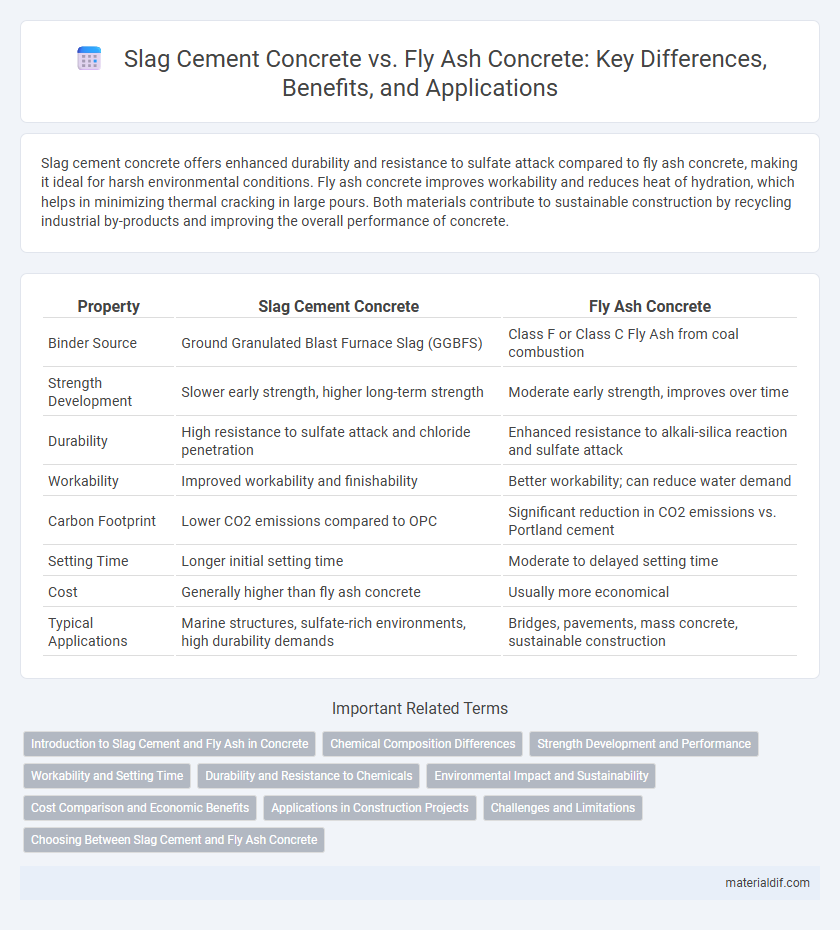

Slag cement concrete offers enhanced durability and resistance to sulfate attack compared to fly ash concrete, making it ideal for harsh environmental conditions. Fly ash concrete improves workability and reduces heat of hydration, which helps in minimizing thermal cracking in large pours. Both materials contribute to sustainable construction by recycling industrial by-products and improving the overall performance of concrete.

Table of Comparison

| Property | Slag Cement Concrete | Fly Ash Concrete |

|---|---|---|

| Binder Source | Ground Granulated Blast Furnace Slag (GGBFS) | Class F or Class C Fly Ash from coal combustion |

| Strength Development | Slower early strength, higher long-term strength | Moderate early strength, improves over time |

| Durability | High resistance to sulfate attack and chloride penetration | Enhanced resistance to alkali-silica reaction and sulfate attack |

| Workability | Improved workability and finishability | Better workability; can reduce water demand |

| Carbon Footprint | Lower CO2 emissions compared to OPC | Significant reduction in CO2 emissions vs. Portland cement |

| Setting Time | Longer initial setting time | Moderate to delayed setting time |

| Cost | Generally higher than fly ash concrete | Usually more economical |

| Typical Applications | Marine structures, sulfate-rich environments, high durability demands | Bridges, pavements, mass concrete, sustainable construction |

Introduction to Slag Cement and Fly Ash in Concrete

Slag cement, derived from granulated blast furnace slag, enhances concrete durability and resistance to chemical attack by promoting denser microstructures. Fly ash, a byproduct of coal combustion, improves workability and long-term strength of concrete through pozzolanic reactions that reduce permeability. Both materials serve as supplementary cementitious components, optimizing sustainability and performance in concrete mixtures.

Chemical Composition Differences

Slag cement concrete primarily contains calcium silicates, aluminates, and ferrites derived from granulated blast furnace slag, resulting in lower calcium oxide content compared to fly ash concrete. Fly ash concrete consists mainly of aluminosilicate glass with higher levels of silica, alumina, and iron oxide, contributing to its pozzolanic properties. The distinct chemical compositions influence hydration reactions, mechanical strength, and durability characteristics in each type of concrete.

Strength Development and Performance

Slag cement concrete exhibits higher early strength gain due to its latent hydraulic properties, enhancing durability and resistance to chemical attacks compared to fly ash concrete. Fly ash concrete, while slower in strength development, improves workability and long-term strength through pozzolanic reactions, resulting in reduced permeability and enhanced sulfate resistance. Both materials contribute to sustainable construction by utilizing industrial byproducts, but slag cement concrete offers superior early performance whereas fly ash concrete excels in durability over extended periods.

Workability and Setting Time

Slag cement concrete typically exhibits improved workability due to its smoother particle texture, which enhances flow and reduces water demand compared to fly ash concrete. Fly ash concrete often has a longer setting time because of the slower pozzolanic reaction, providing extended workability but delaying strength gain. In contrast, slag cement concrete achieves faster setting times, making it suitable for projects requiring quicker formwork removal and early finishing.

Durability and Resistance to Chemicals

Slag cement concrete exhibits superior durability and enhanced resistance to chemical attacks such as sulfates and chlorides compared to fly ash concrete, making it ideal for aggressive environments. Fly ash concrete, while providing moderate chemical resistance, tends to exhibit slower strength gain and reduced durability under prolonged exposure to harsh chemicals. Selecting slag cement concrete improves longevity and structural integrity in infrastructure subjected to corrosive elements.

Environmental Impact and Sustainability

Slag cement concrete reduces CO2 emissions by recycling byproducts from steel production, significantly lowering environmental impact compared to traditional Portland cement. Fly ash concrete utilizes coal combustion residuals, diverting waste from landfills and enhancing durability, which extends the lifespan of concrete structures. Both materials promote sustainability by reducing reliance on virgin raw materials and minimizing the carbon footprint of concrete production.

Cost Comparison and Economic Benefits

Slag cement concrete generally offers lower initial material costs compared to fly ash concrete due to the abundance of ground granulated blast-furnace slag from steel production. Fly ash concrete provides enhanced long-term economic benefits through improved durability and reduced maintenance expenses, leveraging the pozzolanic reaction that increases strength and reduces permeability. Overall, slag cement concrete is often favored for budget-sensitive projects, while fly ash concrete delivers greater lifecycle cost savings in infrastructure requiring longevity.

Applications in Construction Projects

Slag cement concrete offers enhanced durability and resistance to sulfate attack, making it ideal for marine structures, bridges, and foundations exposed to harsh environments. Fly ash concrete excels in improving workability and reducing heat of hydration, which is beneficial for large-scale pours in dams, pavements, and high-rise buildings. Both materials contribute to sustainable construction by utilizing industrial by-products and improving the long-term performance of concrete structures.

Challenges and Limitations

Slag cement concrete faces challenges such as slower early strength gain and potential variability in slag quality, which can affect consistency and durability. Fly ash concrete limitations include reduced early strength development and sensitivity to curing conditions, potentially leading to reduced freeze-thaw resistance. Both materials require careful mix design adjustment and quality control to optimize performance in structural applications.

Choosing Between Slag Cement and Fly Ash Concrete

Slag cement concrete offers enhanced durability and sulfate resistance due to its latent hydraulic properties, making it ideal for harsh environments, while fly ash concrete improves workability and reduces water demand through its pozzolanic reaction, contributing to lower heat of hydration. The choice between slag cement and fly ash concrete depends on project-specific factors such as exposure conditions, desired mechanical properties, and sustainability goals, with slag cement preferred in aggressive chemical environments and fly ash favored for early strength gain and cost efficiency. Consideration of local material availability, curing conditions, and environmental impact also plays a critical role in optimizing concrete performance and longevity.

Slag Cement Concrete vs Fly Ash Concrete Infographic

materialdif.com

materialdif.com