Portland cement is a traditional binder widely used in concrete production, characterized by its high carbon footprint due to clinker calcination. Geopolymer binders offer a sustainable alternative by utilizing industrial by-products such as fly ash and slag, which significantly reduce CO2 emissions during manufacturing. This innovative binder also exhibits superior chemical resistance and durability compared to conventional Portland cement.

Table of Comparison

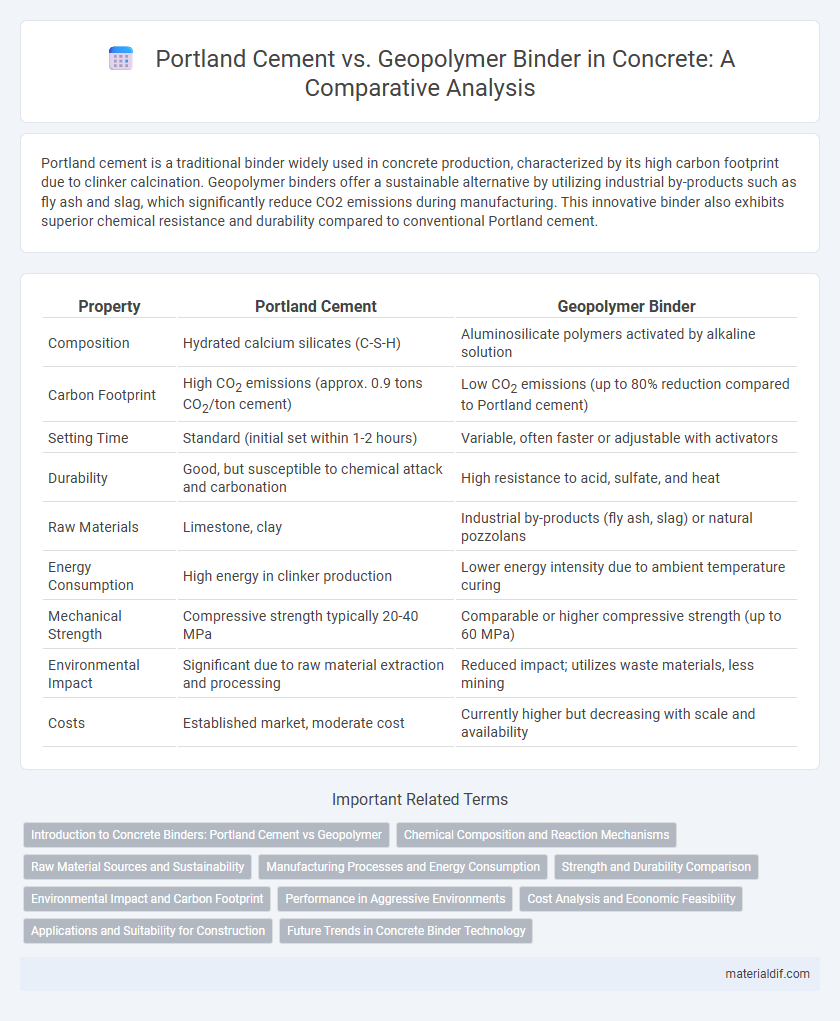

| Property | Portland Cement | Geopolymer Binder |

|---|---|---|

| Composition | Hydrated calcium silicates (C-S-H) | Aluminosilicate polymers activated by alkaline solution |

| Carbon Footprint | High CO2 emissions (approx. 0.9 tons CO2/ton cement) | Low CO2 emissions (up to 80% reduction compared to Portland cement) |

| Setting Time | Standard (initial set within 1-2 hours) | Variable, often faster or adjustable with activators |

| Durability | Good, but susceptible to chemical attack and carbonation | High resistance to acid, sulfate, and heat |

| Raw Materials | Limestone, clay | Industrial by-products (fly ash, slag) or natural pozzolans |

| Energy Consumption | High energy in clinker production | Lower energy intensity due to ambient temperature curing |

| Mechanical Strength | Compressive strength typically 20-40 MPa | Comparable or higher compressive strength (up to 60 MPa) |

| Environmental Impact | Significant due to raw material extraction and processing | Reduced impact; utilizes waste materials, less mining |

| Costs | Established market, moderate cost | Currently higher but decreasing with scale and availability |

Introduction to Concrete Binders: Portland Cement vs Geopolymer

Portland cement, a traditional binder in concrete, primarily consists of calcium silicates that hydrate to form a strong, durable matrix. Geopolymer binders, derived from aluminosilicate materials, offer enhanced chemical resistance and lower carbon emissions compared to Portland cement. Understanding the differences in composition and environmental impact is crucial for optimizing sustainable concrete applications.

Chemical Composition and Reaction Mechanisms

Portland cement primarily consists of calcium silicates, such as tricalcium silicate (C3S) and dicalcium silicate (C2S), which hydrate to form calcium silicate hydrate (C-S-H) gel and calcium hydroxide, driving strength development. Geopolymer binders are aluminosilicate-based materials that polymerize through alkali activation, forming a three-dimensional network of Si-O-Al bonds without producing calcium hydroxide. The chemical reaction mechanisms in Portland cement involve hydration and crystalline product formation, whereas geopolymerization relies on dissolution, reorientation, and polycondensation of silicate and aluminate species.

Raw Material Sources and Sustainability

Portland cement primarily relies on limestone and clay, emitting significant CO2 during calcination, while geopolymer binders utilize industrial byproducts like fly ash or slag, reducing carbon footprint. Geopolymers offer enhanced sustainability by repurposing waste materials and requiring lower energy-intensive processing compared to Portland cement production. This shift supports resource conservation and mitigates environmental impact in the concrete industry.

Manufacturing Processes and Energy Consumption

Portland cement manufacturing involves the calcination of limestone and clay at about 1450degC, consuming substantial energy primarily from fossil fuels, resulting in high CO2 emissions. Geopolymer binders are synthesized at significantly lower temperatures, often below 100degC, using industrial byproducts like fly ash or slag, which reduces energy consumption by up to 80% compared to Portland cement. This lower thermal demand not only cuts energy costs but also minimizes carbon footprint, making geopolymers a sustainable alternative in concrete production.

Strength and Durability Comparison

Portland cement typically achieves compressive strengths ranging from 20 to 40 MPa within 28 days, while geopolymer binders can surpass these values, often reaching strengths above 50 MPa due to their inorganic polymer matrix. Geopolymer concrete exhibits superior durability with enhanced resistance to chemical attack, sulfate exposure, and high temperatures compared to Portland cement-based concrete. The dense microstructure of geopolymer binders reduces permeability, resulting in improved longevity and reduced maintenance costs in aggressive environments.

Environmental Impact and Carbon Footprint

Portland cement production emits approximately 0.9 tons of CO2 per ton of cement, contributing significantly to global greenhouse gas emissions, whereas geopolymer binders can reduce carbon footprint by up to 80% due to lower energy requirements and the use of industrial by-products like fly ash or slag. Geopolymer binders also minimize reliance on limestone calcination, cutting CO2 emissions associated with chemical decomposition in traditional cement manufacturing. This shift to geopolymer technology represents a sustainable alternative in the concrete industry, aligning with efforts to reduce environmental impact and mitigate climate change.

Performance in Aggressive Environments

Portland cement often suffers from reduced durability in aggressive environments due to its susceptibility to sulfate attack, chloride penetration, and carbonation, leading to cracking and deterioration. Geopolymer binders exhibit superior performance by resisting chemical degradation and maintaining structural integrity under harsh conditions such as high acidity, saltwater exposure, and elevated temperatures. Their inherent chemical stability and dense microstructure offer enhanced durability for infrastructure in marine, industrial, and acidic environments.

Cost Analysis and Economic Feasibility

Portland cement production involves high energy consumption and raw material costs, which significantly impact its overall price, whereas geopolymer binders utilize industrial by-products like fly ash and slag, reducing feedstock expenditure. Geopolymer binders demonstrate potential economic benefits through lower energy requirements and reduced carbon taxes, enhancing economic feasibility in sustainable construction projects. A thorough cost analysis reveals that while initial investment in geopolymer technology may be higher, long-term savings from operational efficiency and environmental incentives can offset expenses compared to traditional Portland cement.

Applications and Suitability for Construction

Portland cement is widely used in traditional construction for its strength and durability in concrete structures such as buildings, bridges, and roads, making it suitable for a broad range of load-bearing applications. Geopolymer binders excel in high-performance and sustainable construction projects, offering superior chemical resistance and lower carbon footprint, ideal for industrial flooring, fire-resistant panels, and waste containment. Both materials offer unique advantages depending on environmental conditions and project requirements, with Portland cement favored for conventional infrastructure and geopolymer binders preferred in eco-friendly and specialized applications.

Future Trends in Concrete Binder Technology

Portland cement remains the dominant binder in concrete production, but geopolymer binders are emerging as sustainable alternatives due to their significantly lower carbon footprint and enhanced chemical resistance. Research in future trends highlights the potential of geopolymer technology to reduce greenhouse gas emissions by up to 80% compared to traditional Portland cement. Innovations are focused on optimizing raw material utilization, improving durability, and scaling industrial applications to meet global demands for eco-friendly construction practices.

Portland cement vs geopolymer binder Infographic

materialdif.com

materialdif.com