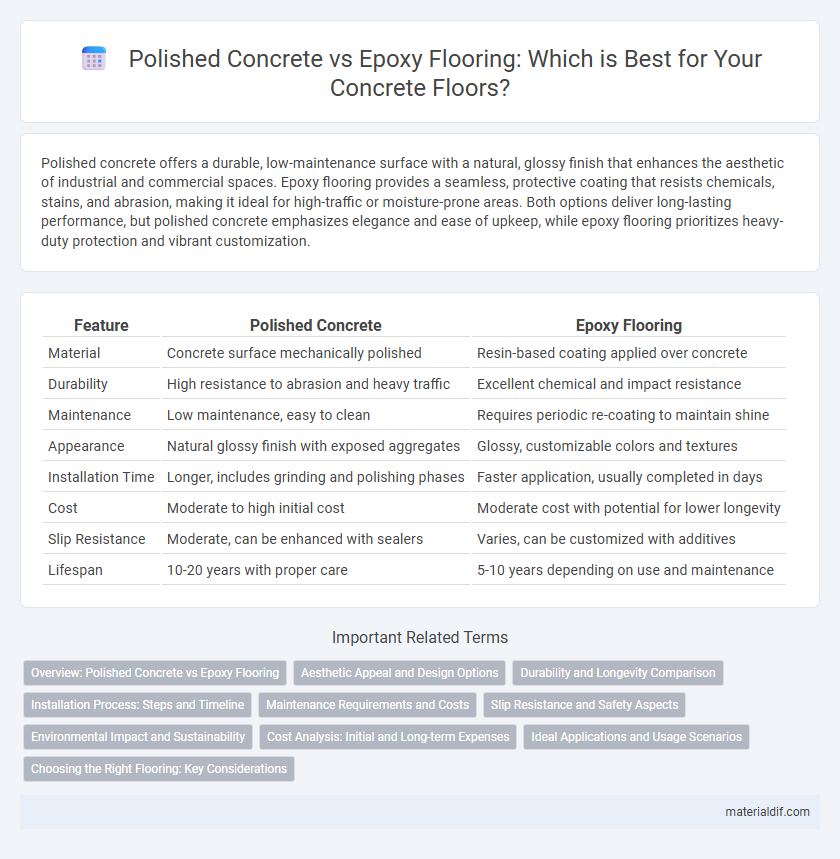

Polished concrete offers a durable, low-maintenance surface with a natural, glossy finish that enhances the aesthetic of industrial and commercial spaces. Epoxy flooring provides a seamless, protective coating that resists chemicals, stains, and abrasion, making it ideal for high-traffic or moisture-prone areas. Both options deliver long-lasting performance, but polished concrete emphasizes elegance and ease of upkeep, while epoxy flooring prioritizes heavy-duty protection and vibrant customization.

Table of Comparison

| Feature | Polished Concrete | Epoxy Flooring |

|---|---|---|

| Material | Concrete surface mechanically polished | Resin-based coating applied over concrete |

| Durability | High resistance to abrasion and heavy traffic | Excellent chemical and impact resistance |

| Maintenance | Low maintenance, easy to clean | Requires periodic re-coating to maintain shine |

| Appearance | Natural glossy finish with exposed aggregates | Glossy, customizable colors and textures |

| Installation Time | Longer, includes grinding and polishing phases | Faster application, usually completed in days |

| Cost | Moderate to high initial cost | Moderate cost with potential for lower longevity |

| Slip Resistance | Moderate, can be enhanced with sealers | Varies, can be customized with additives |

| Lifespan | 10-20 years with proper care | 5-10 years depending on use and maintenance |

Overview: Polished Concrete vs Epoxy Flooring

Polished concrete offers a durable, low-maintenance surface with a natural glossy finish achieved through mechanical grinding and sealing, making it ideal for high-traffic commercial and industrial spaces. Epoxy flooring provides a seamless, customizable coating resistant to chemicals and abrasion, suitable for warehouses, garages, and environments requiring enhanced chemical protection. Both options improve floor longevity and aesthetics, but polished concrete emphasizes natural stone durability, whereas epoxy flooring excels in versatility and surface protection.

Aesthetic Appeal and Design Options

Polished concrete offers a sleek, natural finish with varying sheen levels that enhance the underlying aggregate for a modern, industrial look, while epoxy flooring provides a wide range of colors, patterns, and custom designs, including metallic and decorative chips, allowing for more creative and vibrant aesthetics. The durability and low-maintenance nature of polished concrete makes it ideal for minimalist and contemporary spaces, whereas epoxy's versatility suits both commercial and residential environments seeking bold, customized flooring solutions. Both options can be tailored to specific design needs but differ significantly in texture, reflectivity, and color variety.

Durability and Longevity Comparison

Polished concrete offers exceptional durability with a lifespan of 10-20 years under heavy foot or vehicle traffic due to its dense, abrasion-resistant surface. Epoxy flooring provides strong chemical resistance and impact protection but typically lasts 5-10 years before requiring reapplication or repair. Choosing polished concrete ensures long-term wear with minimal maintenance, while epoxy flooring may need periodic refinishing to maintain its integrity.

Installation Process: Steps and Timeline

Polished concrete installation involves surface grinding, honing, and polishing steps that typically take 2 to 4 days depending on the area size and desired shine level. Epoxy flooring requires thorough surface cleaning and priming, followed by multiple layers of epoxy application with curing times between each coat, usually spanning 3 to 7 days. Thorough surface preparation is critical in both processes to ensure durability and proper adhesion, but epoxy demands longer curing periods compared to the relatively faster polishing timeline.

Maintenance Requirements and Costs

Polished concrete requires minimal maintenance, involving regular dust mopping and occasional wet cleaning, making it cost-effective over time due to its durability and resistance to stains and wear. Epoxy flooring demands more frequent upkeep such as cleaning to prevent yellowing and periodic reapplication to maintain its glossy finish, which increases ongoing maintenance costs. Initial installation costs for polished concrete are typically higher, but reduced maintenance expenses generally result in lower total cost of ownership compared to epoxy flooring.

Slip Resistance and Safety Aspects

Polished concrete offers a naturally textured surface that enhances slip resistance, making it suitable for areas prone to moisture and heavy foot traffic. Epoxy flooring provides a smooth, glossy finish but can become slippery when wet unless additives like anti-slip aggregates are incorporated. Prioritizing slip resistance in both materials is essential for maintaining workplace safety and reducing the risk of falls.

Environmental Impact and Sustainability

Polished concrete offers a sustainable flooring solution by utilizing the existing slab, minimizing the need for additional materials and reducing waste, which lowers its overall environmental footprint. Epoxy flooring involves synthetic resins that require chemical production processes and may emit volatile organic compounds (VOCs), posing challenges for indoor air quality and recyclability. The lifecycle impact of polished concrete generally results in lower carbon emissions and better sustainability, making it a preferred choice for eco-conscious construction projects.

Cost Analysis: Initial and Long-term Expenses

Polished concrete generally offers lower initial costs compared to epoxy flooring due to its simpler installation process and minimal material requirements. Over time, polished concrete requires less maintenance and repair, reducing long-term expenses, while epoxy flooring may necessitate periodic recoating and potential damage repairs that increase overall costs. Evaluating factors like durability, maintenance frequency, and installation complexity is critical for an accurate cost analysis between these flooring options.

Ideal Applications and Usage Scenarios

Polished concrete is ideal for high-traffic commercial spaces, warehouses, and retail environments due to its durability, low maintenance, and natural aesthetic appeal. Epoxy flooring suits industrial facilities, garages, and areas requiring chemical resistance and customizable color finishes, offering superior protection against spills and abrasion. Selecting between polished concrete and epoxy depends on factors such as wear resistance, visual preference, and specific environmental demands.

Choosing the Right Flooring: Key Considerations

Polished concrete offers durability, low maintenance, and a natural, glossy finish ideal for high-traffic areas, while epoxy flooring provides superior chemical resistance, a wider range of color options, and seamless installation suited for industrial or decorative environments. Key considerations include the intended use, budget, longevity, and aesthetic preferences, with polished concrete typically favored for sustainability and cost-effectiveness, whereas epoxy is chosen for customization and enhanced protection. Evaluating factors such as slip resistance, curing time, and maintenance requirements ensures the choice aligns with specific functional and design needs.

Polished Concrete vs Epoxy Flooring Infographic

materialdif.com

materialdif.com