Fiber-reinforced concrete offers enhanced crack resistance and durability by dispersing fibers throughout the mix, making it ideal for pet structures requiring impact absorption. Steel-reinforced concrete provides superior tensile strength and load-bearing capacity, suitable for larger or more heavily used pet enclosures. Choosing between fiber and steel reinforcement depends on the specific design needs, maintenance considerations, and environmental exposure of the pet concrete application.

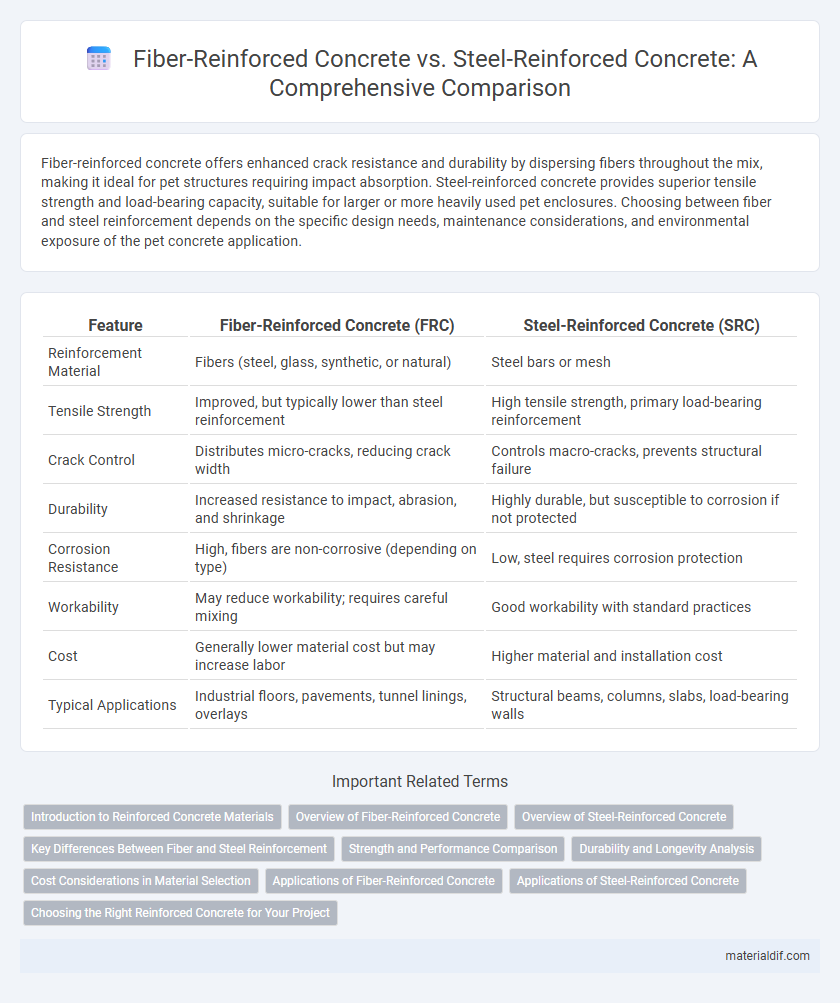

Table of Comparison

| Feature | Fiber-Reinforced Concrete (FRC) | Steel-Reinforced Concrete (SRC) |

|---|---|---|

| Reinforcement Material | Fibers (steel, glass, synthetic, or natural) | Steel bars or mesh |

| Tensile Strength | Improved, but typically lower than steel reinforcement | High tensile strength, primary load-bearing reinforcement |

| Crack Control | Distributes micro-cracks, reducing crack width | Controls macro-cracks, prevents structural failure |

| Durability | Increased resistance to impact, abrasion, and shrinkage | Highly durable, but susceptible to corrosion if not protected |

| Corrosion Resistance | High, fibers are non-corrosive (depending on type) | Low, steel requires corrosion protection |

| Workability | May reduce workability; requires careful mixing | Good workability with standard practices |

| Cost | Generally lower material cost but may increase labor | Higher material and installation cost |

| Typical Applications | Industrial floors, pavements, tunnel linings, overlays | Structural beams, columns, slabs, load-bearing walls |

Introduction to Reinforced Concrete Materials

Fiber-reinforced concrete incorporates discrete fibers such as steel, glass, or synthetic materials to enhance tensile strength, crack resistance, and durability. Steel-reinforced concrete relies on steel bars or mesh embedded within the concrete to provide structural support and improve load-bearing capacity. Both materials improve concrete's performance, but fiber reinforcement offers better crack control while steel reinforcement delivers higher tensile strength for heavy structural applications.

Overview of Fiber-Reinforced Concrete

Fiber-reinforced concrete (FRC) incorporates discrete fibers such as steel, glass, or synthetic materials that enhance tensile strength and crack resistance without requiring traditional steel rebar. The microstructure improvement provided by fibers increases durability, reduces shrinkage, and controls plastic shrinkage cracking, making FRC suitable for pavements, industrial floors, and precast elements. Compared to steel-reinforced concrete, FRC offers improved impact resistance and energy absorption while simplifying construction processes by minimizing corrosion concerns associated with steel reinforcement.

Overview of Steel-Reinforced Concrete

Steel-reinforced concrete combines concrete's compressive strength with steel's tensile strength, creating a composite material widely used in construction. This reinforcement method enhances structural durability, crack resistance, and load-bearing capacity in buildings, bridges, and infrastructure projects. Steel rebar embedded within concrete ensures improved performance under tension, making it a preferred choice for structural frameworks and heavy-duty applications.

Key Differences Between Fiber and Steel Reinforcement

Fiber-reinforced concrete incorporates discrete fibers such as steel, glass, or synthetic materials to enhance tensile strength and control cracking, while steel-reinforced concrete uses continuous steel bars or mesh for primary structural support. Fiber reinforcement improves durability by distributing stress and reducing shrinkage cracks, whereas steel reinforcement provides superior load-bearing capacity and ductility. The choice between fiber and steel reinforcement depends on project requirements, with fibers offering easier placement and reduced corrosion risk, and steel reinforcing critical structural elements subject to heavy loads.

Strength and Performance Comparison

Fiber-reinforced concrete offers improved crack resistance and impact strength due to the uniform distribution of synthetic or steel fibers within the matrix, enhancing tensile strength and durability. Steel-reinforced concrete provides higher load-bearing capacity and superior flexural strength, making it ideal for structural elements subjected to heavy stress. Overall, fiber-reinforced concrete excels in controlling shrinkage cracks and improving toughness, while steel reinforcement delivers greater performance under high compressive and bending forces.

Durability and Longevity Analysis

Fiber-reinforced concrete (FRC) offers superior crack resistance and improved durability under dynamic loading due to the distribution of synthetic or steel fibers within the matrix, reducing micro-crack propagation. Steel-reinforced concrete provides robust structural strength but is vulnerable to corrosion over time, especially in aggressive environments, which can compromise longevity without adequate protective measures. Studies indicate that fiber-reinforced concrete demonstrates enhanced service life and reduced maintenance costs by mitigating corrosion-induced deterioration commonly observed in traditional steel-reinforced concrete structures.

Cost Considerations in Material Selection

Fiber-reinforced concrete generally offers lower initial material costs compared to steel-reinforced concrete due to reduced labor and installation expenses. While steel reinforcement demands specialized handling and corrosion protection, fibers can be easily mixed into the concrete, lowering overall project costs. Lifecycle cost analysis often favors fiber-reinforced concrete in applications requiring improved durability and reduced maintenance.

Applications of Fiber-Reinforced Concrete

Fiber-reinforced concrete (FRC) enhances structural performance by improving crack resistance and durability in pavement, industrial flooring, and tunnel linings. Its application is prevalent in shotcrete for slope stabilization and precast concrete products where tensile strength and impact resistance are critical. FRC is favored in infrastructure requiring reduced maintenance and extended service life, such as bridge decks and airport runways.

Applications of Steel-Reinforced Concrete

Steel-reinforced concrete is extensively used in high-rise buildings, bridges, and heavy infrastructure projects, providing exceptional tensile strength and durability. Its ability to withstand dynamic loads and resist cracking makes it ideal for structural elements like beams, slabs, and columns. This reinforcement method enhances the concrete's performance in seismic zones and industrial flooring, where high load-bearing capacity is critical.

Choosing the Right Reinforced Concrete for Your Project

Fiber-reinforced concrete offers enhanced crack resistance and improved durability through the distribution of synthetic or steel fibers, making it ideal for applications requiring high tensile strength and minimal maintenance. Steel-reinforced concrete provides superior structural support and load-bearing capacity due to embedded steel bars, preferred in large-scale construction like bridges and high-rise buildings. Selecting between fiber and steel reinforcement depends on project-specific factors such as load demands, environmental exposure, and long-term performance requirements.

Fiber-Reinforced Concrete vs Steel-Reinforced Concrete Infographic

materialdif.com

materialdif.com