Air-entrained concrete contains microscopic air bubbles that improve its durability and resistance to freeze-thaw cycles, making it ideal for cold climates. Non-air-entrained concrete lacks these bubbles, resulting in higher density and strength but increased susceptibility to cracking under freeze-thaw stress. Choosing between air-entrained and non-air-entrained concrete depends on environmental conditions and specific performance requirements.

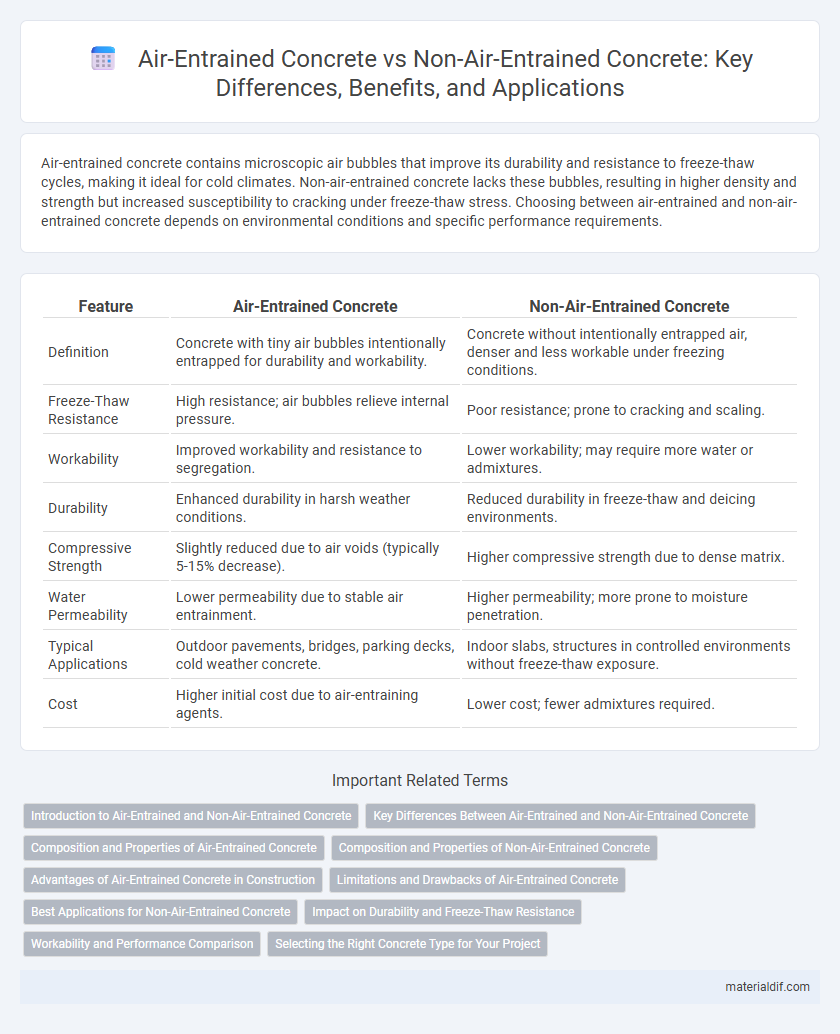

Table of Comparison

| Feature | Air-Entrained Concrete | Non-Air-Entrained Concrete |

|---|---|---|

| Definition | Concrete with tiny air bubbles intentionally entrapped for durability and workability. | Concrete without intentionally entrapped air, denser and less workable under freezing conditions. |

| Freeze-Thaw Resistance | High resistance; air bubbles relieve internal pressure. | Poor resistance; prone to cracking and scaling. |

| Workability | Improved workability and resistance to segregation. | Lower workability; may require more water or admixtures. |

| Durability | Enhanced durability in harsh weather conditions. | Reduced durability in freeze-thaw and deicing environments. |

| Compressive Strength | Slightly reduced due to air voids (typically 5-15% decrease). | Higher compressive strength due to dense matrix. |

| Water Permeability | Lower permeability due to stable air entrainment. | Higher permeability; more prone to moisture penetration. |

| Typical Applications | Outdoor pavements, bridges, parking decks, cold weather concrete. | Indoor slabs, structures in controlled environments without freeze-thaw exposure. |

| Cost | Higher initial cost due to air-entraining agents. | Lower cost; fewer admixtures required. |

Introduction to Air-Entrained and Non-Air-Entrained Concrete

Air-entrained concrete contains microscopic air bubbles intentionally introduced during mixing to enhance durability and resistance to freeze-thaw cycles, making it ideal for cold climates. Non-air-entrained concrete lacks these air bubbles, offering higher density and compressive strength but lower resistance to freeze damage. The choice between air-entrained and non-air-entrained concrete depends on environmental exposure and structural requirements, balancing strength and durability.

Key Differences Between Air-Entrained and Non-Air-Entrained Concrete

Air-entrained concrete contains microscopic air bubbles that improve freeze-thaw durability and resistance to scaling, whereas non-air-entrained concrete lacks these bubbles and is more susceptible to cracking in cold climates. The air void system in air-entrained concrete enhances workability and reduces water demand, leading to better overall durability and longevity. In contrast, non-air-entrained concrete typically exhibits higher strength but lower resistance to exposure-related damage, making it suitable for applications in milder environments.

Composition and Properties of Air-Entrained Concrete

Air-entrained concrete contains tiny, uniformly distributed air bubbles introduced through air-entraining agents, enhancing durability and resistance to freeze-thaw cycles by reducing internal stress. The air voids improve workability and reduce bleeding without compromising compressive strength significantly, distinguishing it from non-air-entrained concrete, which lacks these microscopic air pockets and is more prone to cracking under freeze-thaw conditions. This composition makes air-entrained concrete ideal for cold climates and structures exposed to moisture, offering superior longevity and structural integrity.

Composition and Properties of Non-Air-Entrained Concrete

Non-air-entrained concrete is composed primarily of cement, fine and coarse aggregates, and water, without intentional incorporation of microscopic air bubbles. This type of concrete exhibits higher density and compressive strength due to its lower porosity but is more susceptible to freeze-thaw damage and scaling in cold climates. Its properties offer greater resistance to abrasion and chemical attack, making it suitable for structures not exposed to harsh weather conditions.

Advantages of Air-Entrained Concrete in Construction

Air-entrained concrete improves durability by enhancing resistance to freeze-thaw cycles and reducing scaling in cold climates. It increases workability, allowing for easier placement and finishing without compromising strength. The microscopic air bubbles also provide better flexibility under stress, minimizing cracking and extending the lifespan of concrete structures.

Limitations and Drawbacks of Air-Entrained Concrete

Air-entrained concrete, while enhancing freeze-thaw durability, faces limitations such as reduced compressive strength compared to non-air-entrained concrete, typically by 5 to 15 percent. Its increased air content can lead to lower density and altered workability, potentially impacting structural applications that require high strength. Additionally, improper air-entrainment can cause issues like excessive air voids, which may result in surface blemishes and decreased durability under certain exposure conditions.

Best Applications for Non-Air-Entrained Concrete

Non-air-entrained concrete is best applied in environments where freeze-thaw cycles are minimal and water exposure is limited, such as indoor floors, foundations, and pavements in dry climates. Its lower air content enhances compressive strength and durability in structural applications without severe weathering effects. This type of concrete is ideal for projects demanding high strength and abrasion resistance rather than freeze-thaw resistance.

Impact on Durability and Freeze-Thaw Resistance

Air-entrained concrete contains microscopic air bubbles that improve its durability by reducing internal pressure during freeze-thaw cycles, thereby preventing cracking and scaling. Non-air-entrained concrete lacks this protective air void system, making it more susceptible to freeze-thaw damage and decreased lifespan in cold climates. The enhanced freeze-thaw resistance of air-entrained concrete significantly extends the service life of concrete structures exposed to harsh environmental conditions.

Workability and Performance Comparison

Air-entrained concrete improves workability by incorporating microscopic air bubbles that enhance slump and ease of placement, especially in cold weather applications, whereas non-air-entrained concrete tends to be stiffer and less workable. The performance of air-entrained concrete excels in freeze-thaw durability and resistance to scaling, reducing cracking and extending lifespan, while non-air-entrained concrete is more susceptible to damage under cyclical freezing conditions. However, non-air-entrained concrete typically achieves higher compressive strength due to the absence of air voids that slightly reduce density.

Selecting the Right Concrete Type for Your Project

Air-entrained concrete incorporates microscopic air bubbles to enhance freeze-thaw durability and resistance to scaling, making it ideal for outdoor or cold climate projects. Non-air-entrained concrete offers higher compressive strength and is suitable for interior or non-freezing environments where surface wear is minimal. Selecting the right concrete type depends on environmental exposure, structural requirements, and durability needs to ensure long-term performance and cost efficiency.

Air-Entrained Concrete vs Non-Air-Entrained Concrete Infographic

materialdif.com

materialdif.com