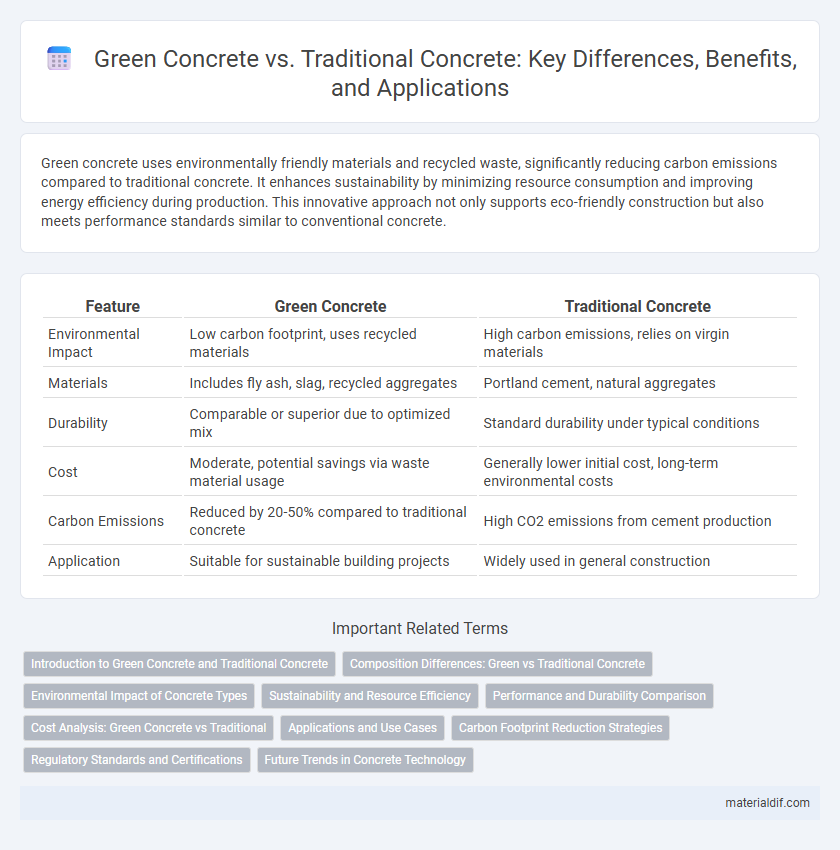

Green concrete uses environmentally friendly materials and recycled waste, significantly reducing carbon emissions compared to traditional concrete. It enhances sustainability by minimizing resource consumption and improving energy efficiency during production. This innovative approach not only supports eco-friendly construction but also meets performance standards similar to conventional concrete.

Table of Comparison

| Feature | Green Concrete | Traditional Concrete |

|---|---|---|

| Environmental Impact | Low carbon footprint, uses recycled materials | High carbon emissions, relies on virgin materials |

| Materials | Includes fly ash, slag, recycled aggregates | Portland cement, natural aggregates |

| Durability | Comparable or superior due to optimized mix | Standard durability under typical conditions |

| Cost | Moderate, potential savings via waste material usage | Generally lower initial cost, long-term environmental costs |

| Carbon Emissions | Reduced by 20-50% compared to traditional concrete | High CO2 emissions from cement production |

| Application | Suitable for sustainable building projects | Widely used in general construction |

Introduction to Green Concrete and Traditional Concrete

Green concrete incorporates eco-friendly materials such as recycled aggregates, fly ash, and slag cement to reduce carbon emissions, enhance sustainability, and minimize environmental impact. Traditional concrete primarily relies on cement, water, sand, and natural aggregates, resulting in higher carbon footprints due to cement production. Advances in green concrete technology aim to improve durability and reduce resource consumption without compromising structural integrity.

Composition Differences: Green vs Traditional Concrete

Green concrete incorporates industrial byproducts such as fly ash, slag, and recycled aggregates, reducing reliance on Portland cement and lowering carbon emissions. Traditional concrete primarily consists of cement, water, sand, and natural coarse aggregates, contributing to higher energy consumption and environmental impact. The substitution of eco-friendly materials in green concrete enhances sustainability without compromising structural integrity.

Environmental Impact of Concrete Types

Green concrete significantly reduces carbon emissions by incorporating industrial by-products such as fly ash and slag, lowering the use of Portland cement which is a major source of CO2. Traditional concrete's production emits approximately 900 kg of CO2 per cubic meter, whereas green concrete can cut these emissions by up to 30-40%. Utilizing recycled materials and waste products in green concrete also decreases landfill waste and conserves natural resources, contributing to a more sustainable construction industry.

Sustainability and Resource Efficiency

Green concrete significantly reduces carbon emissions by incorporating waste materials such as fly ash and slag, enhancing sustainability compared to traditional concrete. It utilizes recycled aggregates and industrial by-products, promoting resource efficiency and reducing landfill waste. This eco-friendly approach supports long-term environmental benefits by minimizing natural resource extraction and energy consumption during production.

Performance and Durability Comparison

Green concrete, composed of recycled materials and industrial byproducts like fly ash and slag, demonstrates enhanced durability through improved resistance to chemical attacks and reduced permeability. Traditional concrete, primarily made from Portland cement and aggregates, tends to exhibit higher carbon footprints and is more susceptible to cracking and environmental degradation over time. Performance-wise, green concrete provides comparable or superior compressive strength while promoting sustainability and extending structural lifespan.

Cost Analysis: Green Concrete vs Traditional

Green concrete often incurs higher initial costs due to the use of recycled materials and advanced production techniques, yet it offers long-term savings through increased durability and reduced maintenance expenses. Traditional concrete generally has lower upfront costs but may require more frequent repairs and replacements, leading to higher lifecycle costs. Evaluating cost-effectiveness involves considering environmental benefits alongside direct financial impacts to determine the most sustainable choice.

Applications and Use Cases

Green concrete, made using recycled materials and industrial by-products, excels in sustainable construction projects, such as eco-friendly buildings, road pavements, and water infrastructure, reducing carbon footprint. Traditional concrete remains favored in high-strength applications like bridges, dams, and heavy-load foundations due to its proven durability and structural performance. Both types offer specific benefits, with green concrete prioritized for environmental impact in residential and commercial developments, while traditional concrete supports critical infrastructure demanding maximum strength.

Carbon Footprint Reduction Strategies

Green concrete incorporates alternative materials such as fly ash, slag, and recycled aggregates to significantly reduce carbon emissions compared to traditional Portland cement, which is responsible for approximately 8% of global CO2 emissions. Carbon footprint reduction strategies in green concrete emphasize the use of low-energy production methods, incorporation of industrial by-products, and enhanced durability to extend service life and reduce lifecycle emissions. Innovations like carbon capture technologies and geopolymer cements further contribute to lowering the environmental impact of concrete production.

Regulatory Standards and Certifications

Green concrete complies with increasingly stringent environmental regulatory standards such as LEED and BREEAM certifications, emphasizing reduced carbon emissions and sustainable material usage. Traditional concrete often meets basic structural and durability codes but lacks specific environmental certifications that track lifecycle impacts. Regulatory frameworks increasingly favor green concrete for projects targeting net-zero carbon goals and sustainability certifications.

Future Trends in Concrete Technology

Green concrete integrates industrial byproducts like fly ash and slag to reduce carbon emissions, representing a key trend in sustainable construction materials. Advancements in nano-materials and bio-based additives enhance the durability and environmental performance of green concrete compared to traditional Portland cement mixtures. Future concrete technology emphasizes carbon capture, recycling, and self-healing properties to minimize environmental impact and extend infrastructure lifespan.

Green Concrete vs Traditional Concrete Infographic

materialdif.com

materialdif.com