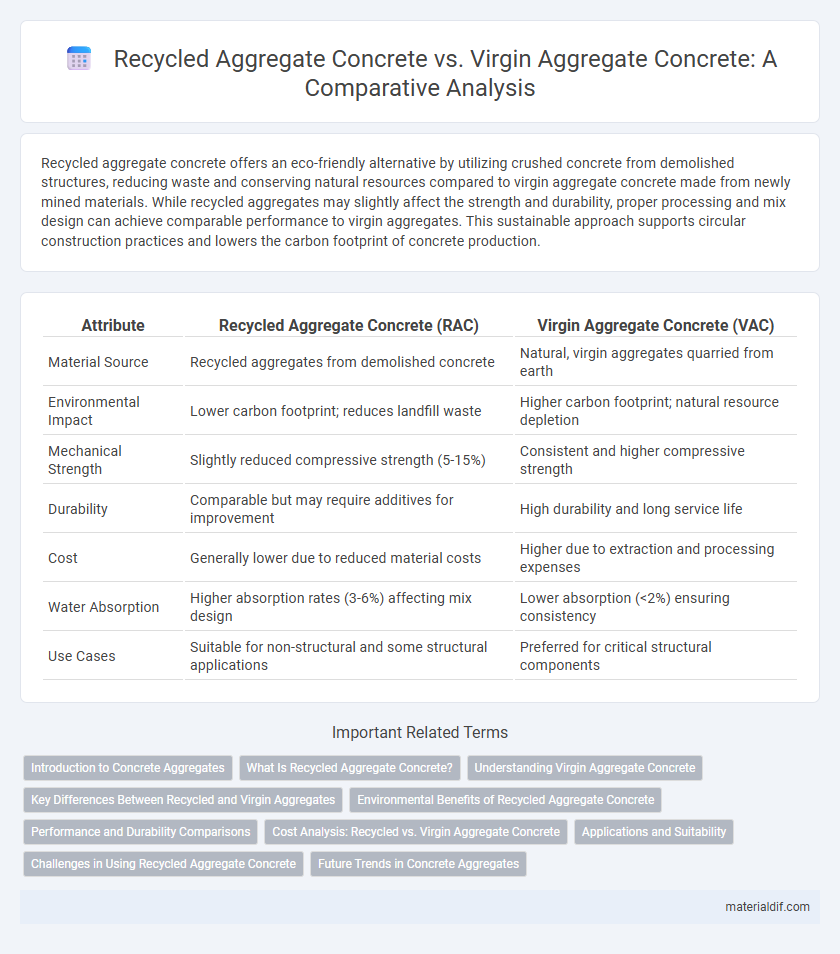

Recycled aggregate concrete offers an eco-friendly alternative by utilizing crushed concrete from demolished structures, reducing waste and conserving natural resources compared to virgin aggregate concrete made from newly mined materials. While recycled aggregates may slightly affect the strength and durability, proper processing and mix design can achieve comparable performance to virgin aggregates. This sustainable approach supports circular construction practices and lowers the carbon footprint of concrete production.

Table of Comparison

| Attribute | Recycled Aggregate Concrete (RAC) | Virgin Aggregate Concrete (VAC) |

|---|---|---|

| Material Source | Recycled aggregates from demolished concrete | Natural, virgin aggregates quarried from earth |

| Environmental Impact | Lower carbon footprint; reduces landfill waste | Higher carbon footprint; natural resource depletion |

| Mechanical Strength | Slightly reduced compressive strength (5-15%) | Consistent and higher compressive strength |

| Durability | Comparable but may require additives for improvement | High durability and long service life |

| Cost | Generally lower due to reduced material costs | Higher due to extraction and processing expenses |

| Water Absorption | Higher absorption rates (3-6%) affecting mix design | Lower absorption (<2%) ensuring consistency |

| Use Cases | Suitable for non-structural and some structural applications | Preferred for critical structural components |

Introduction to Concrete Aggregates

Concrete aggregates play a critical role in determining the strength and durability of concrete mixes. Recycled aggregate concrete (RAC) utilizes processed materials from demolished concrete structures, offering a sustainable alternative to traditional virgin aggregate concrete (VAC) sourced from natural quarries. The selection between recycled and virgin aggregates significantly impacts environmental footprint, mechanical properties, and cost efficiency in construction projects.

What Is Recycled Aggregate Concrete?

Recycled Aggregate Concrete (RAC) is a sustainable construction material made by replacing virgin aggregates with recycled aggregates derived from crushed concrete debris and demolition waste. RAC offers environmental benefits by reducing landfill waste and conserving natural resources while maintaining comparable structural performance to Virgin Aggregate Concrete (VAC). Its use supports green building practices by lowering carbon footprint and promoting resource efficiency in concrete production.

Understanding Virgin Aggregate Concrete

Virgin Aggregate Concrete consists of natural aggregates extracted directly from quarries or riverbeds, ensuring consistent quality and strength compared to recycled materials. These aggregates provide superior bonding with cement paste, resulting in higher durability and load-bearing capacity for structural applications. Understanding the properties of virgin aggregates, such as particle shape, size distribution, and mineral composition, is crucial for optimizing concrete performance in construction projects.

Key Differences Between Recycled and Virgin Aggregates

Recycled aggregate concrete incorporates aggregates derived from crushed concrete waste, offering environmental benefits and cost savings, while virgin aggregate concrete uses newly extracted natural aggregates known for consistent quality and strength. Key differences include higher porosity and lower density in recycled aggregates, which can affect the concrete's durability and compressive strength compared to virgin aggregates. The variability in recycled aggregate properties necessitates careful mix design and quality control to achieve performance comparable to virgin aggregate concrete.

Environmental Benefits of Recycled Aggregate Concrete

Recycled Aggregate Concrete (RAC) significantly reduces environmental impact by minimizing landfill waste and decreasing the extraction of natural resources compared to Virgin Aggregate Concrete. The use of recycled aggregates lowers the carbon footprint of concrete production due to reduced energy consumption in material processing and transportation. Incorporating recycled aggregates also conserves natural habitats and mitigates resource depletion, promoting sustainable construction practices.

Performance and Durability Comparisons

Recycled Aggregate Concrete (RAC) demonstrates comparable compressive strength to Virgin Aggregate Concrete (VAC) when optimized mix designs are used, although RAC may exhibit slightly higher water absorption rates due to the presence of adhered mortar. Durability assessments reveal that RAC can achieve similar resistance to freeze-thaw cycles and chloride ion penetration, but proper treatment of recycled aggregates is crucial to mitigate porosity and improve interfacial transition zones. Long-term performance studies indicate that with adequate quality control, RAC offers sustainable alternatives without significant compromises in structural integrity or lifespan compared to conventional VAC.

Cost Analysis: Recycled vs. Virgin Aggregate Concrete

Recycled aggregate concrete (RAC) typically offers cost savings of 10-30% compared to virgin aggregate concrete due to lower material procurement expenses and reduced landfill fees. Virgin aggregate concrete involves higher costs associated with quarrying, transportation, and environmental compliance, driving overall project budgets upward. Lifecycle analyses often highlight RAC's economic benefits when factoring in sustainability incentives and reduced carbon taxes.

Applications and Suitability

Recycled aggregate concrete (RAC) is widely used in non-structural applications such as pavements, sidewalks, and landscaping due to its cost-effectiveness and environmental benefits, while virgin aggregate concrete (VAC) remains preferred for high-strength structural components like bridges and high-rise buildings because of its superior durability and performance consistency. RAC is suitable for sustainable construction projects seeking LEED certification and reduced carbon footprint, though VAC offers enhanced load-bearing capacity and long-term reliability for critical infrastructure. The choice between RAC and VAC depends on specific project requirements, balancing sustainability goals with structural demands.

Challenges in Using Recycled Aggregate Concrete

Recycled Aggregate Concrete (RAC) presents challenges such as lower compressive strength and higher water absorption compared to Virgin Aggregate Concrete (VAC), impacting durability and structural performance. Variability in recycled aggregate quality, including contaminants and adhered mortar, leads to inconsistent concrete properties and potential long-term deterioration. Addressing these issues requires advanced processing techniques and mix design optimization to achieve performance parity with conventional VAC.

Future Trends in Concrete Aggregates

Recycled Aggregate Concrete (RAC) is gaining significant traction due to its sustainability benefits, reducing reliance on natural resources and minimizing construction waste. Advancements in processing technologies are enhancing the quality and performance of recycled aggregates, making RAC increasingly comparable to Virgin Aggregate Concrete (VAC) in durability and strength. Emerging trends suggest a growing integration of recycled materials in high-performance concrete applications, driven by stricter environmental regulations and the global push towards circular economy practices in the construction sector.

Recycled Aggregate Concrete vs Virgin Aggregate Concrete Infographic

materialdif.com

materialdif.com