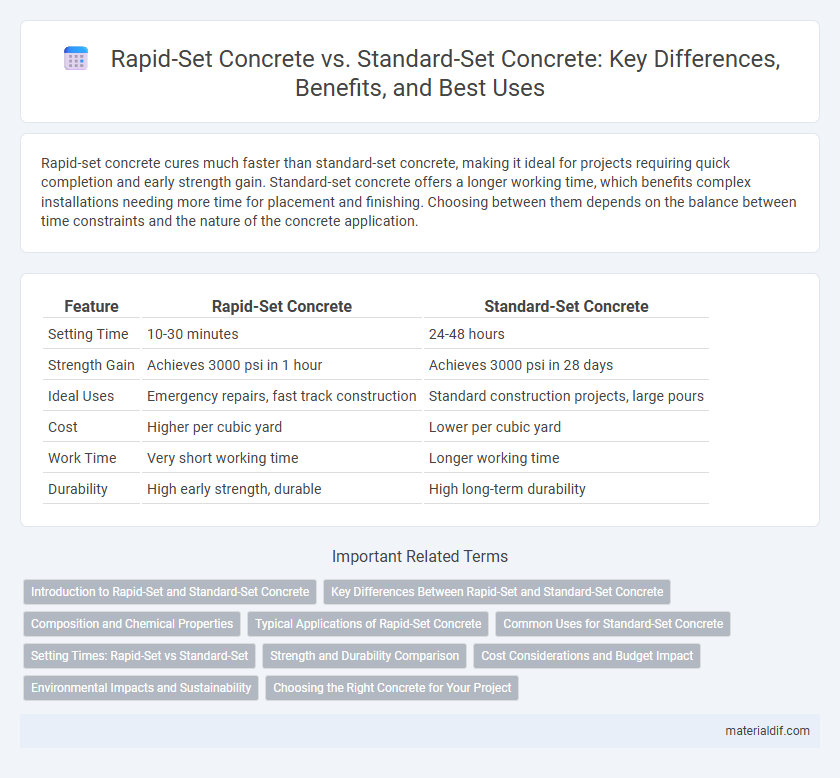

Rapid-set concrete cures much faster than standard-set concrete, making it ideal for projects requiring quick completion and early strength gain. Standard-set concrete offers a longer working time, which benefits complex installations needing more time for placement and finishing. Choosing between them depends on the balance between time constraints and the nature of the concrete application.

Table of Comparison

| Feature | Rapid-Set Concrete | Standard-Set Concrete |

|---|---|---|

| Setting Time | 10-30 minutes | 24-48 hours |

| Strength Gain | Achieves 3000 psi in 1 hour | Achieves 3000 psi in 28 days |

| Ideal Uses | Emergency repairs, fast track construction | Standard construction projects, large pours |

| Cost | Higher per cubic yard | Lower per cubic yard |

| Work Time | Very short working time | Longer working time |

| Durability | High early strength, durable | High long-term durability |

Introduction to Rapid-Set and Standard-Set Concrete

Rapid-set concrete cures significantly faster than standard-set concrete, reaching initial set times within 15 to 30 minutes compared to several hours for standard formulations. This accelerated curing process is ideal for time-sensitive construction projects requiring early strength development. Standard-set concrete, made with ordinary Portland cement, provides a predictable setting time and long-term durability suited for typical structural applications.

Key Differences Between Rapid-Set and Standard-Set Concrete

Rapid-set concrete achieves initial set in as little as 15 minutes, making it ideal for time-sensitive projects, while standard-set concrete typically takes 24 to 48 hours to set. The high early strength of rapid-set formulations supports faster load application, whereas standard-set mixes develop strength more gradually, reaching full capacity in 28 days. Rapid-set concrete often contains special accelerators and additives to enhance curing speed, contrasting with the more straightforward composition of standard-set concrete designed for typical construction schedules.

Composition and Chemical Properties

Rapid-set concrete typically contains higher proportions of calcium aluminate cement and accelerators such as calcium chloride, which significantly reduce the setting time by promoting faster hydration reactions. Standard-set concrete primarily uses ordinary Portland cement with a balanced mix of silicates and aluminates, resulting in a slower, controlled curing process as calcium silicate hydrates form over time. The chemical properties of rapid-set concrete emphasize rapid exothermic reactions and early strength gain, while standard-set concrete focuses on long-term durability and gradual strength development through slower oxidation and crystallization processes.

Typical Applications of Rapid-Set Concrete

Rapid-set concrete is ideal for emergency repairs, road patching, and fast-track construction projects due to its quick curing time, often setting within 15 to 60 minutes. Its typical applications include airport runways, bridge decks, and industrial floors where minimal downtime is crucial. This type of concrete is also preferred for utility repairs and precast concrete elements requiring rapid turnaround.

Common Uses for Standard-Set Concrete

Standard-set concrete is commonly used in residential and commercial construction projects such as sidewalks, driveways, foundations, and slabs where extended working time is necessary for proper placement and finishing. It allows builders to accommodate complex formwork, detailed reinforcement, and transportation over long distances without premature setting. Its durable strength and versatility make it suitable for large-scale infrastructure, including bridges and roadways, that require gradual curing for optimal structural integrity.

Setting Times: Rapid-Set vs Standard-Set

Rapid-set concrete typically sets within 15 to 30 minutes, enabling faster project turnover and early strength development. Standard-set concrete generally requires 24 to 48 hours to set, allowing more working time but delaying subsequent construction activities. Choosing between rapid-set and standard-set concrete depends on project timelines and specific application requirements where early strength or extended workability is prioritized.

Strength and Durability Comparison

Rapid-set concrete achieves initial strength within 1 to 4 hours, making it ideal for projects requiring quick turnaround, while standard-set concrete typically reaches similar strength levels after 24 to 48 hours. In terms of long-term durability, both types demonstrate comparable compressive strengths, often exceeding 3,000 psi, but rapid-set formulations may include additives that enhance resistance to freeze-thaw cycles and chemical exposure. Selecting rapid-set concrete is advantageous for time-sensitive repairs, whereas standard-set concrete remains preferred for conventional construction due to its well-established curing and performance profile.

Cost Considerations and Budget Impact

Rapid-set concrete typically incurs higher initial costs compared to standard-set concrete due to specialized additives that accelerate curing time. However, the reduced labor hours and faster project completion with rapid-set concrete often lead to overall cost savings and minimized budget overruns. In construction budgeting, the decision between rapid-set and standard-set concrete should weigh upfront material expenses against time-sensitive financial benefits and operational efficiencies.

Environmental Impacts and Sustainability

Rapid-set concrete reduces construction time, minimizing onsite emissions and energy consumption compared to standard-set concrete, which requires longer curing periods. The accelerated curing process of rapid-set concrete often decreases water usage, enhancing sustainability by conserving vital resources. However, rapid-set formulations may involve higher energy inputs during production, necessitating a balanced assessment of lifecycle environmental impacts.

Choosing the Right Concrete for Your Project

Rapid-set concrete cures significantly faster than standard-set concrete, making it ideal for projects with tight deadlines or urgent repairs. Standard-set concrete offers superior long-term strength and durability, suitable for large-scale construction requiring extended curing times. Selecting the right concrete depends on project timeline, environmental conditions, and structural requirements to ensure optimal performance and longevity.

Rapid-Set Concrete vs Standard-Set Concrete Infographic

materialdif.com

materialdif.com