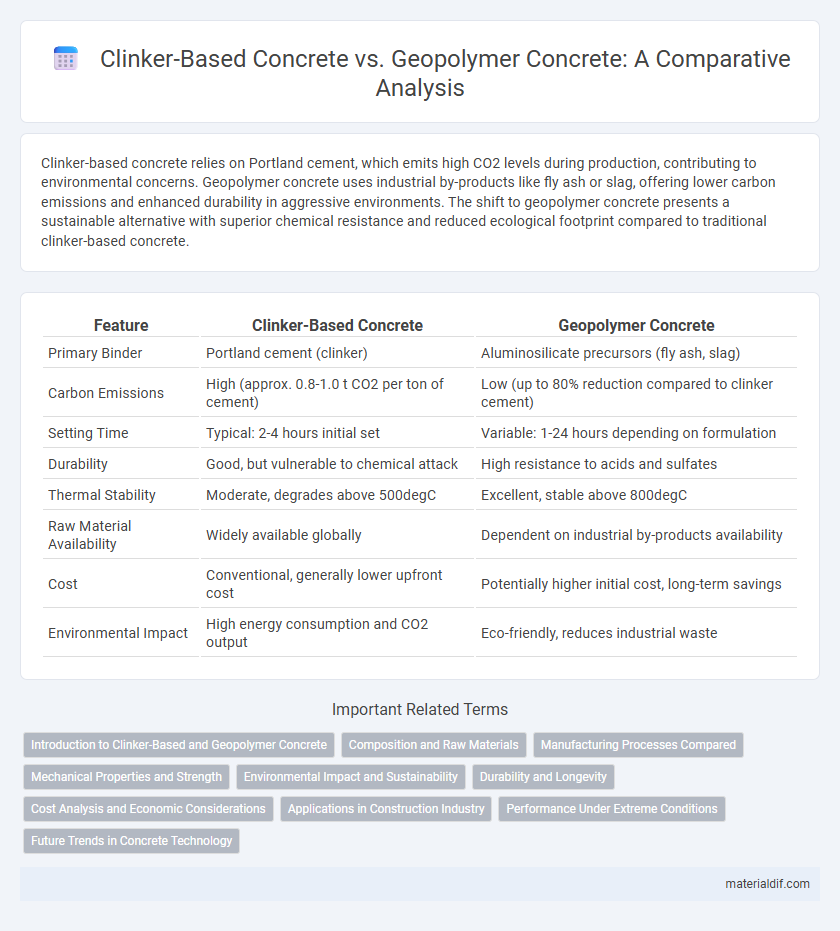

Clinker-based concrete relies on Portland cement, which emits high CO2 levels during production, contributing to environmental concerns. Geopolymer concrete uses industrial by-products like fly ash or slag, offering lower carbon emissions and enhanced durability in aggressive environments. The shift to geopolymer concrete presents a sustainable alternative with superior chemical resistance and reduced ecological footprint compared to traditional clinker-based concrete.

Table of Comparison

| Feature | Clinker-Based Concrete | Geopolymer Concrete |

|---|---|---|

| Primary Binder | Portland cement (clinker) | Aluminosilicate precursors (fly ash, slag) |

| Carbon Emissions | High (approx. 0.8-1.0 t CO2 per ton of cement) | Low (up to 80% reduction compared to clinker cement) |

| Setting Time | Typical: 2-4 hours initial set | Variable: 1-24 hours depending on formulation |

| Durability | Good, but vulnerable to chemical attack | High resistance to acids and sulfates |

| Thermal Stability | Moderate, degrades above 500degC | Excellent, stable above 800degC |

| Raw Material Availability | Widely available globally | Dependent on industrial by-products availability |

| Cost | Conventional, generally lower upfront cost | Potentially higher initial cost, long-term savings |

| Environmental Impact | High energy consumption and CO2 output | Eco-friendly, reduces industrial waste |

Introduction to Clinker-Based and Geopolymer Concrete

Clinker-based concrete relies primarily on Portland cement as its binding agent, produced through the calcination of limestone and clay at high temperatures, resulting in a material known for its high compressive strength and durability. Geopolymer concrete utilizes aluminosilicate materials such as fly ash or metakaolin activated by alkaline solutions, offering enhanced resistance to chemical attacks and significantly lower carbon emissions compared to traditional cement. Both types serve structural applications, yet geopolymer concrete presents a sustainable alternative by reducing reliance on clinker, the primary source of CO2 emissions in cement production.

Composition and Raw Materials

Clinker-based concrete primarily consists of Portland cement clinker combined with aggregates, water, and additives, relying heavily on limestone, clay, and gypsum as raw materials. Geopolymer concrete uses industrial by-products such as fly ash or slag activated with alkaline solutions, significantly reducing the use of traditional cement and lowering carbon emissions. The key distinction lies in the chemical composition; clinker-based concrete relies on calcium silicate hydrate for strength, whereas geopolymer concrete forms aluminosilicate bonds through geopolymerization.

Manufacturing Processes Compared

Clinker-based concrete manufacturing involves the calcination of limestone and clay at high temperatures to produce clinker, which is then ground into cement and mixed with aggregates and water. Geopolymer concrete manufacturing utilizes industrial by-products like fly ash or slag, activated with alkaline solutions, resulting in lower energy consumption and reduced carbon emissions. The geopolymer process eliminates the need for clinker production, making it more environmentally sustainable and less energy-intensive compared to traditional clinker-based methods.

Mechanical Properties and Strength

Clinker-based concrete typically exhibits higher compressive strength due to the calcium silicate phases formed during hydration, providing robust mechanical properties suitable for structural applications. Geopolymer concrete, synthesized from aluminosilicate materials activated by alkaline solutions, demonstrates superior tensile strength and enhanced resistance to chemical and thermal degradation. Studies reveal geopolymer concrete's rapid strength gain and long-term durability surpass traditional clinker-based concrete, making it ideal for sustainable construction requiring high-performance materials.

Environmental Impact and Sustainability

Clinker-based concrete generates significant carbon dioxide emissions during cement production, contributing to approximately 7-8% of global CO2 emissions, which raises concerns about its environmental sustainability. Geopolymer concrete, utilizing industrial by-products such as fly ash or slag, offers a low-carbon alternative by reducing reliance on traditional Portland cement and lowering greenhouse gas emissions by up to 80%. The durability and resistance to chemical attacks of geopolymer concrete further enhance its sustainability by extending service life and reducing maintenance needs in infrastructure projects.

Durability and Longevity

Clinker-based concrete exhibits high compressive strength but is prone to chemical attacks and carbonation, potentially reducing its lifespan in aggressive environments. Geopolymer concrete offers superior resistance to sulfate and acid attacks due to its aluminosilicate structure, enhancing long-term durability and reducing maintenance costs. Studies indicate geopolymer concrete can achieve service lives exceeding 50 years in harsh conditions, outperforming traditional clinker-based formulations.

Cost Analysis and Economic Considerations

Clinker-based concrete typically incurs higher production costs due to the energy-intensive calcination process and reliance on limited raw materials like limestone and clay. Geopolymer concrete offers cost advantages by utilizing industrial by-products such as fly ash and slag, reducing energy consumption and raw material expenses. Economic considerations include potential savings in carbon taxes and long-term durability benefits, making geopolymer concrete increasingly attractive for sustainable construction projects.

Applications in Construction Industry

Clinker-based concrete remains the dominant material in traditional construction due to its proven strength, durability, and ease of use in infrastructure projects such as bridges, buildings, and roads. Geopolymer concrete offers sustainable advantages with lower carbon emissions and superior chemical resistance, making it ideal for specialized applications like waste containment, marine structures, and fire-resistant buildings. The construction industry increasingly adopts geopolymer concrete for eco-friendly projects, while clinker-based concrete continues to serve large-scale conventional construction needs.

Performance Under Extreme Conditions

Clinker-based concrete exhibits high compressive strength but tends to degrade under high temperatures and chemical attack, leading to reduced durability in extreme environments. Geopolymer concrete demonstrates superior resistance to fire, acid, and sulfate exposure due to its inorganic polymer binder, maintaining mechanical stability where traditional concrete fails. Studies show geopolymer concrete's enhanced thermal stability and corrosion resistance make it ideal for infrastructure subjected to harsh conditions.

Future Trends in Concrete Technology

Clinker-based concrete remains the dominant material in construction due to its established performance and global availability, but geopolymer concrete is rapidly gaining attention for its lower carbon footprint and enhanced durability properties. Innovations in geopolymer technology aim to optimize alkaline activator formulations and incorporate industrial by-products like fly ash and slag, significantly reducing CO2 emissions linked to traditional Portland cement production. Future trends in concrete technology prioritize sustainability, durability, and performance, positioning geopolymer concrete as a key alternative in eco-friendly infrastructure development.

Clinker-Based Concrete vs Geopolymer Concrete Infographic

materialdif.com

materialdif.com